Welcome to HongChang Aluminum CO., LTD.

Visit

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Welcome to HongChang Aluminum CO., LTD.

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Double-layer coated thermal CTP plates are usually used for printing jobs that require high quality and efficiency.

Processless thermal CTP plate is a type of plate material specially designed for computer-to-plate (CTP) technology, featuring significant characteristics such as environmental protection, high efficiency, and high quality.

CTCP plates are widely used in the printing industry, especially for high-volume commercial printing jobs where speed and quality are crucial.

Thermal CTP plates have the advantages of fast plate making speed, high tolerance, accurate dot reproduction, excellent ink balance, etc., and are widely used in the printing industry.

The double layer coated sunlight type CTCP plate has high sensitivity, good developing latitude, excellent resolution, consistency, chemical resistance, and printing effect without the need for baking.

Among the wide range of CTP plate types available, high-sensitivity thermal CTP plates have emerged as the preferred solution for increasing production capacity, optimizing costs, and ensuring exceptional print quality.

CTCP refers to a computer-to-plate imaging process using traditional PS plates (Presensitized Plates) or, in some contexts, CTP plates.

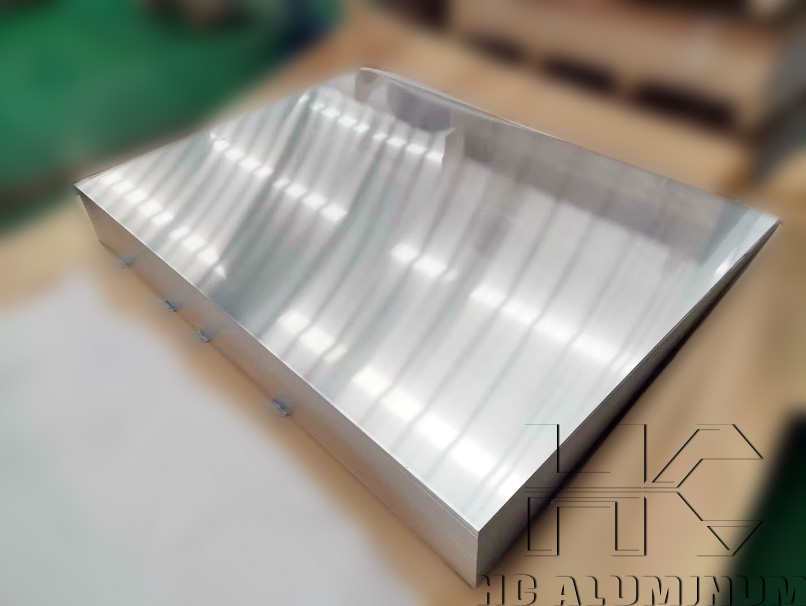

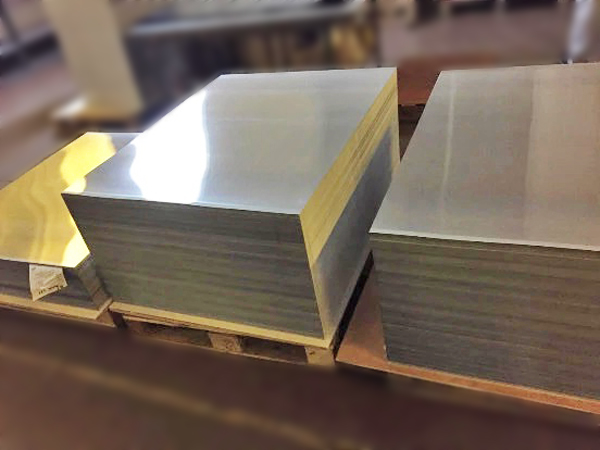

Aluminum plate base for printing plates is an aluminum base used to make printing plates (such as PS plates, CTP plates, etc.). It is widely used in offset printing plates such as positive PS plates, thermal CTP plates, photosensitive CTP plates, UV-CTP p

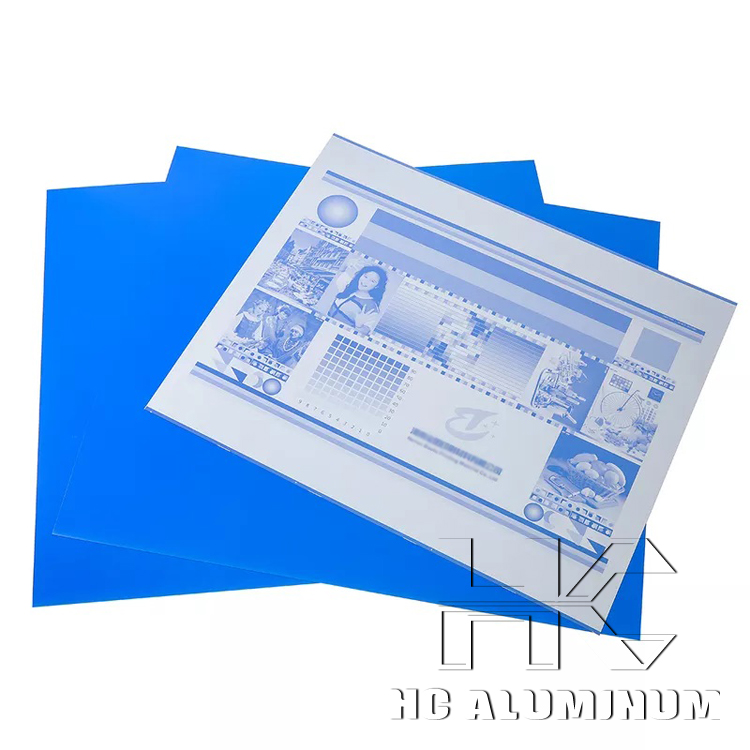

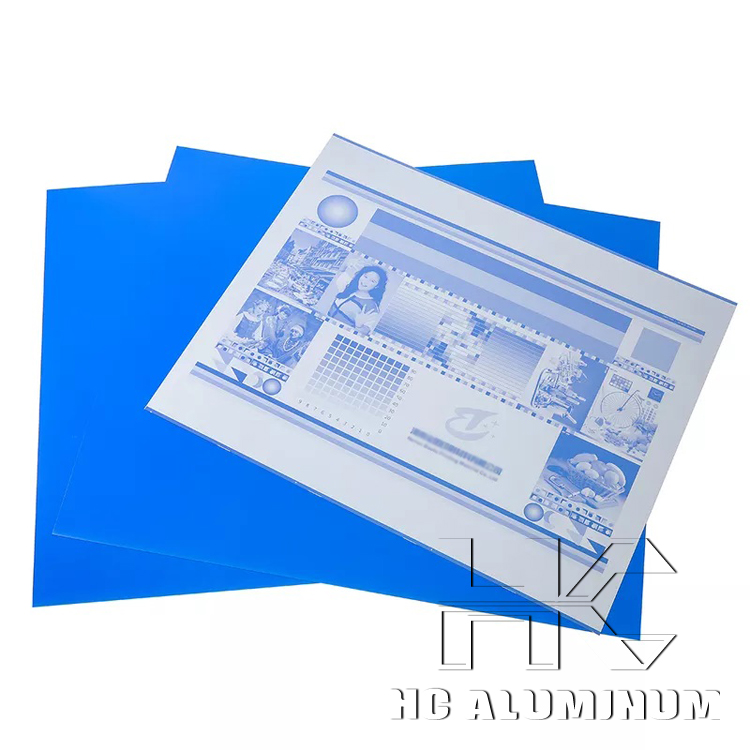

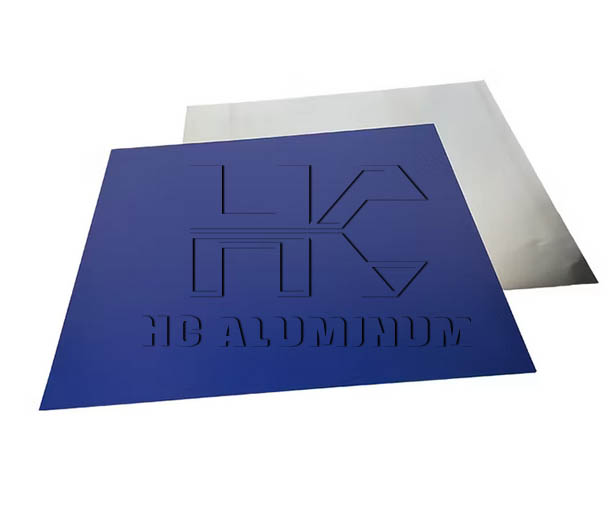

The Blue Positive UV-CTP plate (Computer-to-Plate) is a light-sensitive printing plate based on violet laser technology (405nm), specially designed for UV ink printing environments.

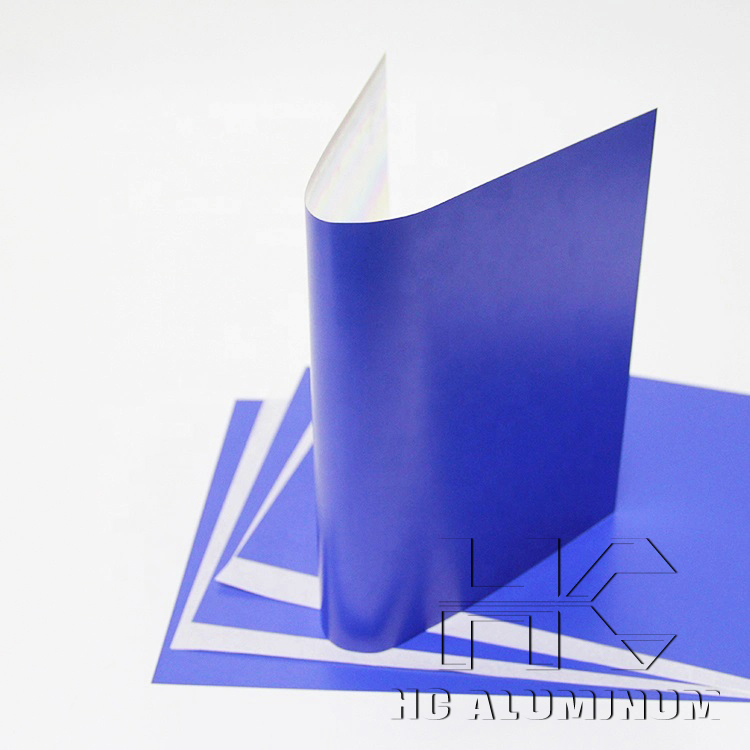

The alloys used for aluminum base sheet production in CTP sheet production are usually 1050, 1060 aluminum coil, etc. Aluminum coil is usually highly processed aluminum, and the surface is anodized to improve corrosion resistance and prepare for subsequen

The mainstream offset printing plates are divided into PS plates and CTP plates. Both have their own characteristics. CTP plate making is gradually becoming the industry's first choice with its many advantages.

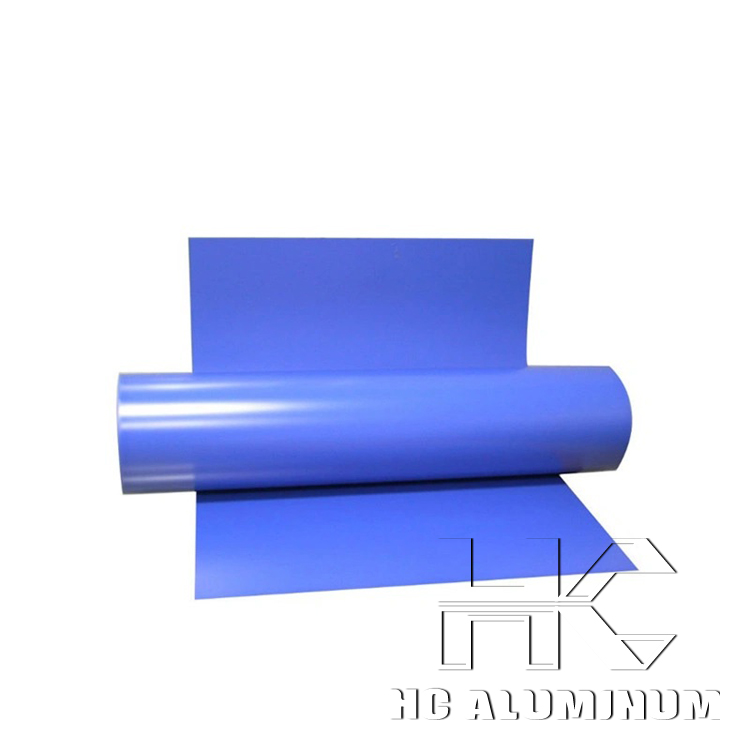

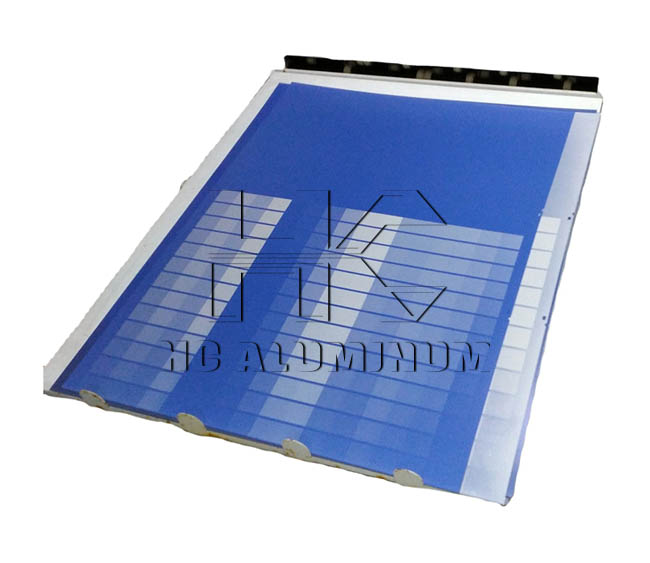

A thermal CTP plate is an aluminum-based printing plate coated with a thermally sensitive imaging layer. It is imaged by an 830 nm thermal laser CTP setter without the use of film, significantly improving prepress efficiency.

Common alloy grades of aluminum sheets commonly used in offset printing are 1050, 1060, 1070, etc., which have the advantages of low density, high strength, and good forming.

Offset thermal CTP aluminum plate is a high-end printing plate made of aluminum plate as the substrate, coated with photosensitive material on the surface, ...

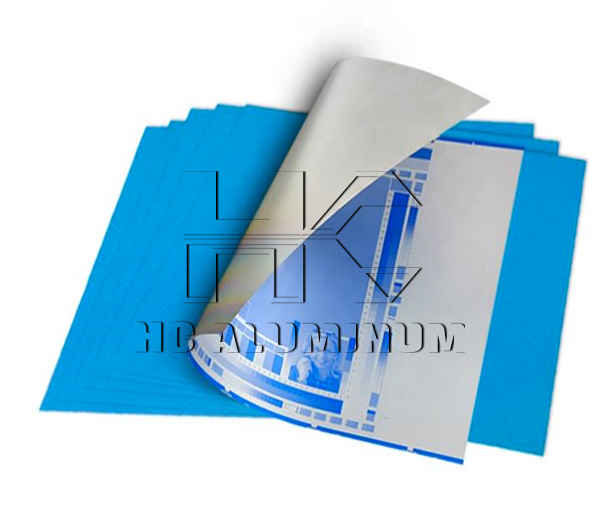

Aluminum CTP plates are widely used in modern printing, especially in commercial printing, book printing and other fields.

Aluminum coils for CTP/PS base plates are mostly made of high-purity aluminum alloys, such as 1050, 1060, 1100, etc. The aluminum content of these alloys is ≥99.50%, ≥99.60% and ≥99.00%, respectively. They have the advantages of high purity, low density,

Keyword,Search Intentbest thermal CTP plates for long run offset printing,Commercialwholesale price per square meter CTP plate for offset,TransactionalUV CTP plates vs thermal CTP plates comparison for offset,Investigational830nm thermal CTP plate manufac

In CTP printing aluminum substrates, the commonly used aluminum plate base alloys are 1050, 1060, etc.

A 0.15mm thick aluminum PS plate is a lightweight printing plate specification, usually made of 1050, 1060 or 1070 series aluminum alloys with a purity of 99.3% or higher.

CTP technology enables direct digital image output onto printing plates, eliminating the need for traditional film-based plate-making.

MC Aluminum is a manufacturer specializing in the production of 1060-h18 aluminum sheets for printing platemaking. The thickness range of production is between 0.13-0.40mm, and it can be customized.

Thermal CTP plates have higher exposure accuracy, more stable imaging characteristics and wider environmental adaptability, and are the preferred plate material in commercial printing, newspaper printing and other fields.

CTCP (Computer to Conventional Plate) printing plate refers to the use of traditional PS plates with direct digital imaging, forming a new generation of UV-CTP plates.

Blue thermal CTP printing plate is the core material in modern printing technology and is widely used in various types of high-precision and large-scale printing production. This printing plate combine

The CTCP plate is mainly composed of a high-quality aluminum substrate and a photosensitive coating.

With the vigorous development of the printing industry, the demand for printing plates has shown a significant growth trend. Among them, the demand for PS plates/CTP plates, which are the main printing plates, is particularly prominent. The PS version of

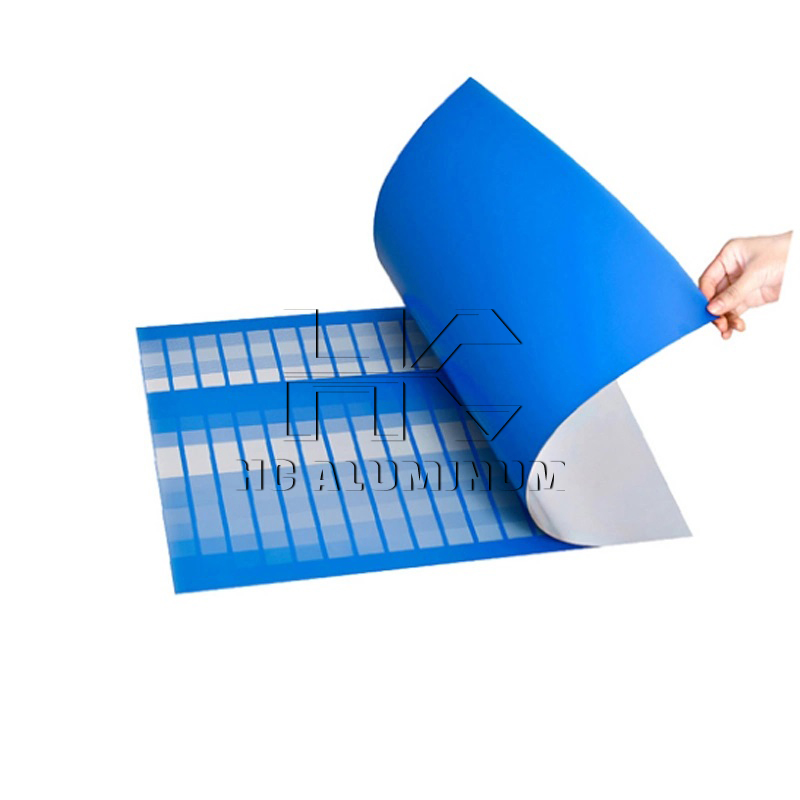

PS/CTP are both rolled into a certain thickness of thin plate through hot and cold rolling process. The surface of the plate is coated with a layer of photosensitive resin after a specific process treatment, and then dried to make a printing plate for var

The biggest advantage for printing companies to use blue CTCP printing plates is the simplification of production processes and the improvement of efficiency.

In the field of newspaper printing, offset printing technology has become mainstream due to its fast speed, stable printing quality and adaptability to large-scale printing.

CTP aluminum substrate made of 1050, 1060, 1070 aluminum sheets, these aluminum alloys are known for their high purity and good processing performance. 1 series aluminum plate can provide good conductivity, ductility and corrosion resistance, suitable for

The PS/CTP base uses 1050/1060 aluminum plate, which ensures printing quality and stability due to its excellent mechanical properties, corrosion resistance and flatness.

Aluminum PS plates are the core consumables of offset printing presses. The base material is primarily 1050, 1060, or 1070 aluminum alloy. The surface is electrolytically oxidized to create a grain structure and then coated with a photosensitive resin.

Thermal CTP plates are commonly available in thicknesses of 0.15mm, 0.20mm, 0.25mm, and 0.30mm. They use thermal technology and are imaged by an 830nm infrared laser, requiring no chemical development, making them suitable for commercial printing applicat

Hongchang Aluminum focuses on the research and development and production of offset printing plates. Its products cover offset printing plates, thermal CTP plates, and raw material aluminum substrates, and are widely used in books, packaging and other fie

Hongchang Aluminum currently produces four main types of CTP plates, including heat-sensitive, silver salt, photopolymerization and processing-free types.