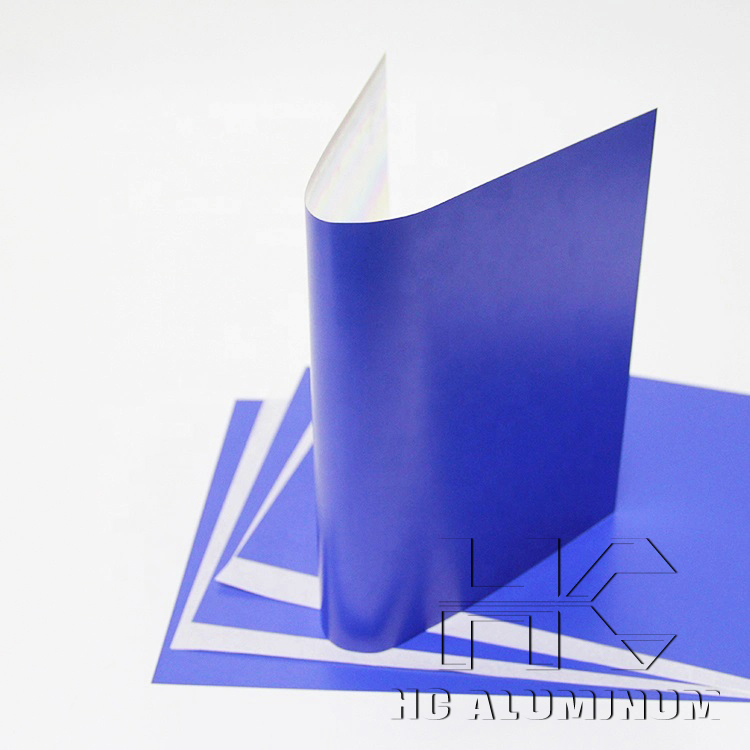

CTCP plates (Computer-to-Conventional Plate), also known as UV CTP plates, are a type of printing plate material that combines traditional printing technology with computer-to-plate (CTP) technology. It utilizes UV light with a wavelength range of 360~450 to expose and image traditional plates, inheriting the advantages of CTP such as timeliness and high quality, while effectively addressing the cost disadvantages of using specialized CTP plates in the prepress duplication process.

What materials are used for UV CTP plates?

UV CTP plates with aluminum base typically use 1-series aluminum alloys, such as 1050A, 1060, 1050, 1070, etc. These alloys have excellent physical properties and chemical stability, making them suitable as the base material for CTP plates.

The aluminum base surface is usually treated with electrolytic oxidation to improve its surface flatness and corrosion resistance, ensuring the printing quality and stability of CTP plates.

CTCP plate technical parameters:

Plate type | CTCP Plate |

| Usage | Offset Printing, Digital Printing |

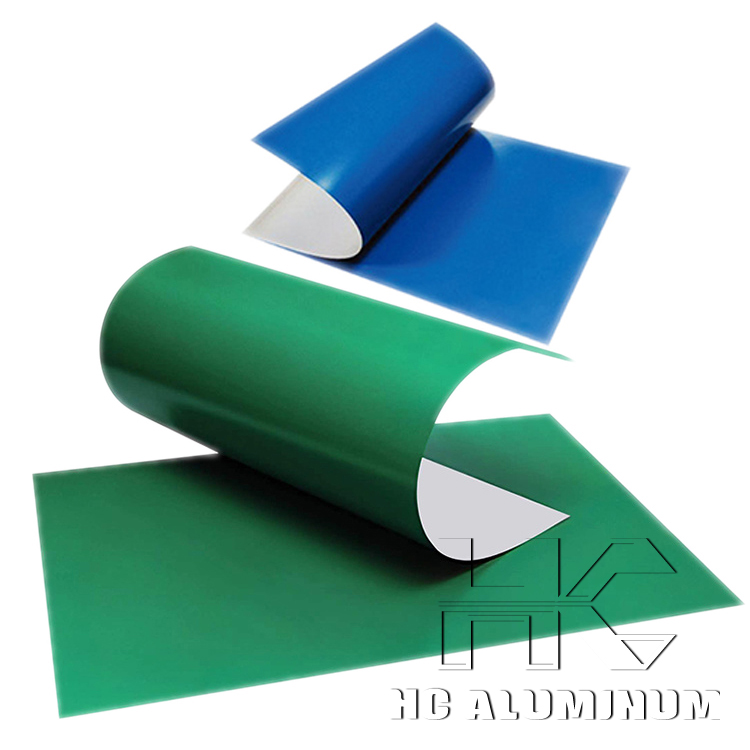

Style | Positive |

Gauge | 0.15mm,0.20mm,0.25mm,0.30mm,0.40mm |

Spectral sensitivity | 410nm |

Exposure energy | 50 - 60 Mj/Cm2 |

Developing temperature | 23+/-2 degree |

Resolution | 2~98% at 200lpi |

Developing time | 30 - 40s |

Run length | 50000 - 100000 impressions |

Shelf time | Shelf time |

Trademark | HONGCHANG or customized |

Transportation Package | Export standard, seaworthy package |

Origin | China |

HS code | 37013024 |

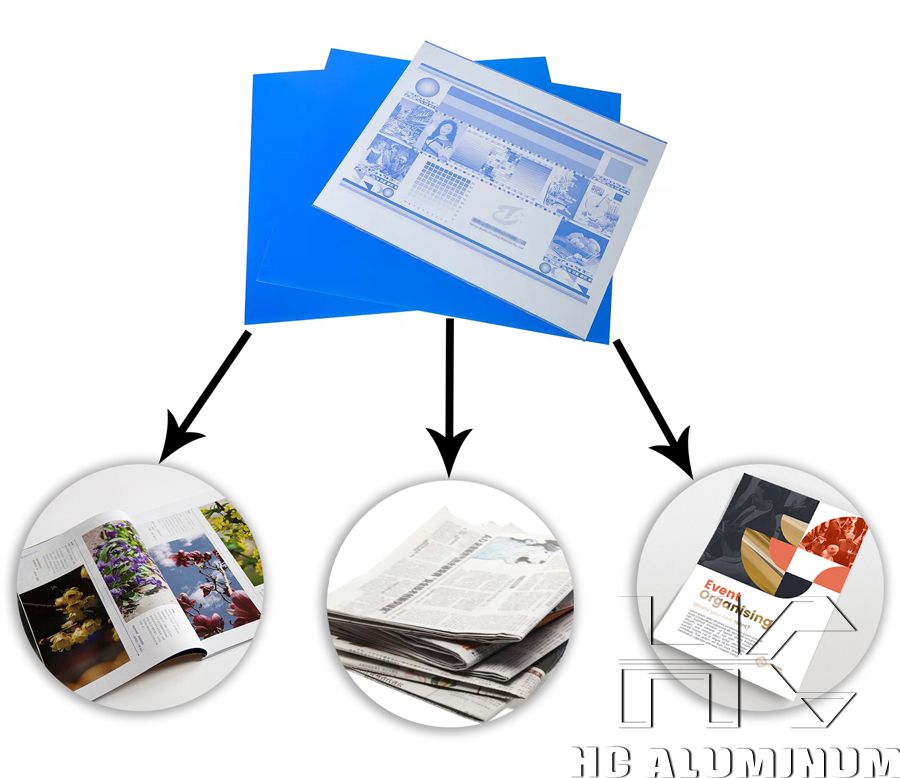

Application

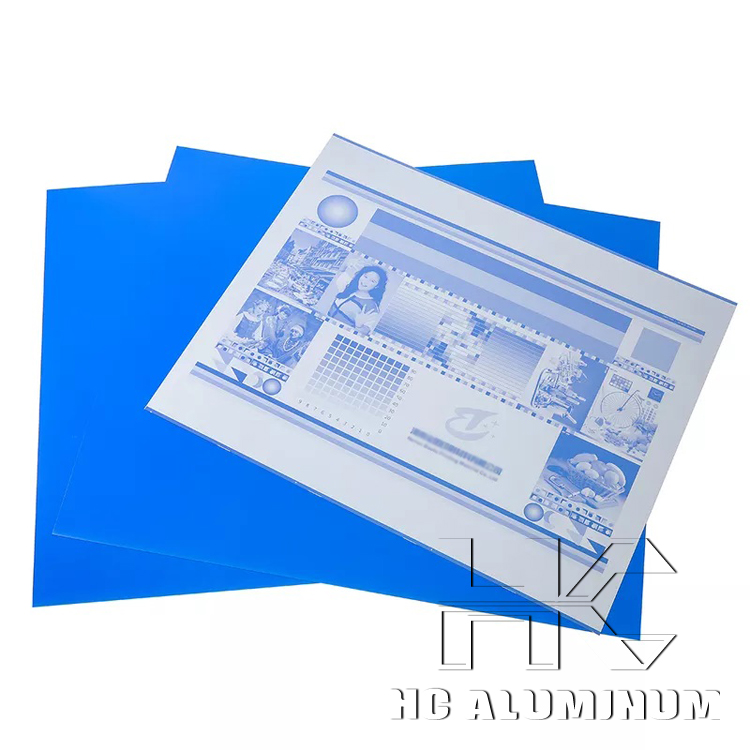

Positive CTCP plate use:

Commercial color printing, packaging printing, book and newspaper printing

Features

Technical advantages of UV CTP plates:

1. Low cost

2. Improved printing quality, precise dot reproduction

3. No need for dirty correction, leading to increased efficiency

4. No need for plate positioning, reducing printing setup time and material waste

5. Simple plate-making process, low cost, high efficiency, low error rate

6. Plate-making operation can be done in a bright room

7. High-quality aluminum base

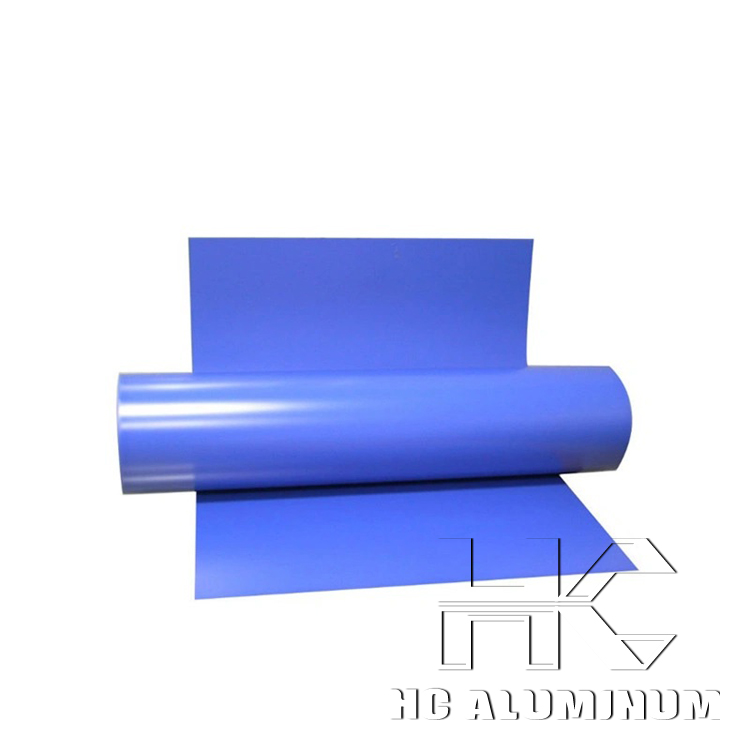

Packaging

1. 15mm 100 pieces/box

2. 30mm 50 pieces/box

Then 50 packages or 1.4 meters high placed on a pallet. A 20-foot container can accommodate 30,000 square meters.