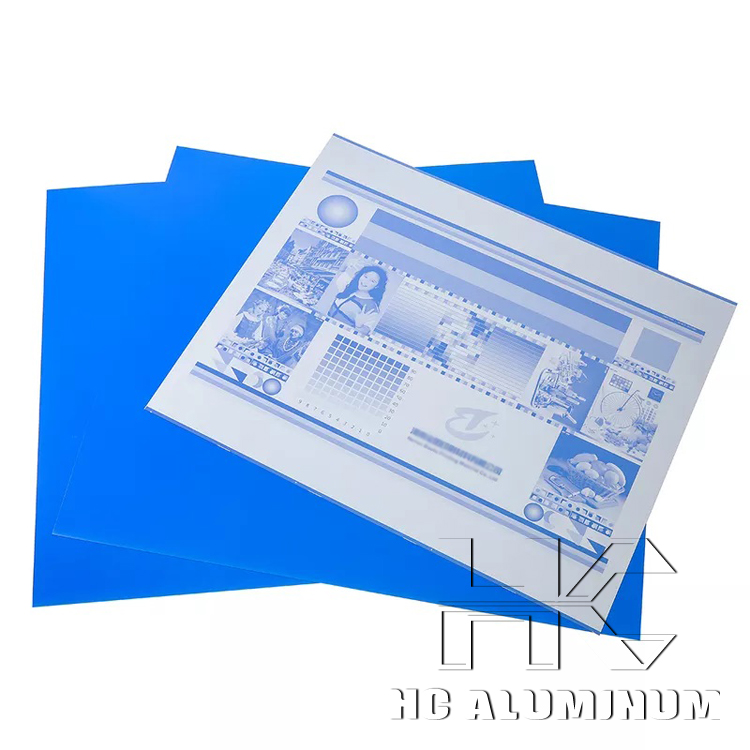

The double-layer thermal UV-CTP plate is specially tailored for UV inks, but also suitable for regular inks. When using regular inks, the plates durability will double. This product is mainly used in high-end commercial color printing and newspaper printing.

Specification

| Product type | Double-layer thermal CTP plate |

| Substrate | Electrochemical grain and cathode electroplating lithographic printing aluminum substrate |

| Aluminum alloy | 1050,1060,1050A |

| Plate thickness | 0.15mm, 0.20mm, 0.25mm, 0.30mm, 0.40mm |

| Max width | 1350mm |

| Spectral sensitivity | 830nm |

| Exposure energy | 110~130mj/Cm2 |

| Developing temperature | 22-28℃ |

| Resolution | 1~99% at 200lpi |

| Developing time | 25-35sec |

| Safety-light | 2hours under white light |

| Trademark | HONGCHANG or customized |

| Origin | China |

| HS code | 37013024 |

Features

Hot CTP plate features:

1. Resistant to UV inks.

2. High-quality aluminum base and photosensitive coating with high durability.

3. Can be operated in daylight.

4. High resolution and precise dot reproduction.

5. High developer tolerance, easy to operate.

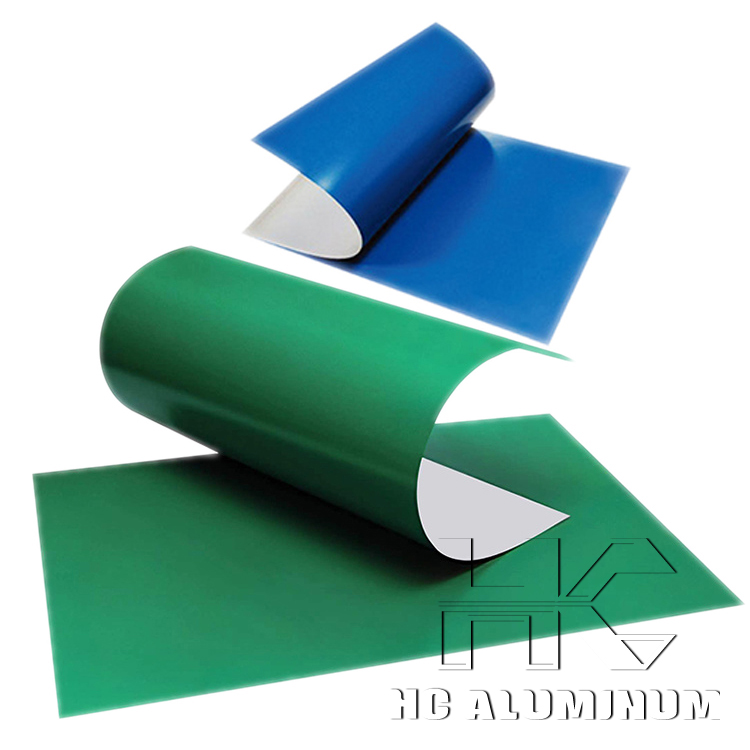

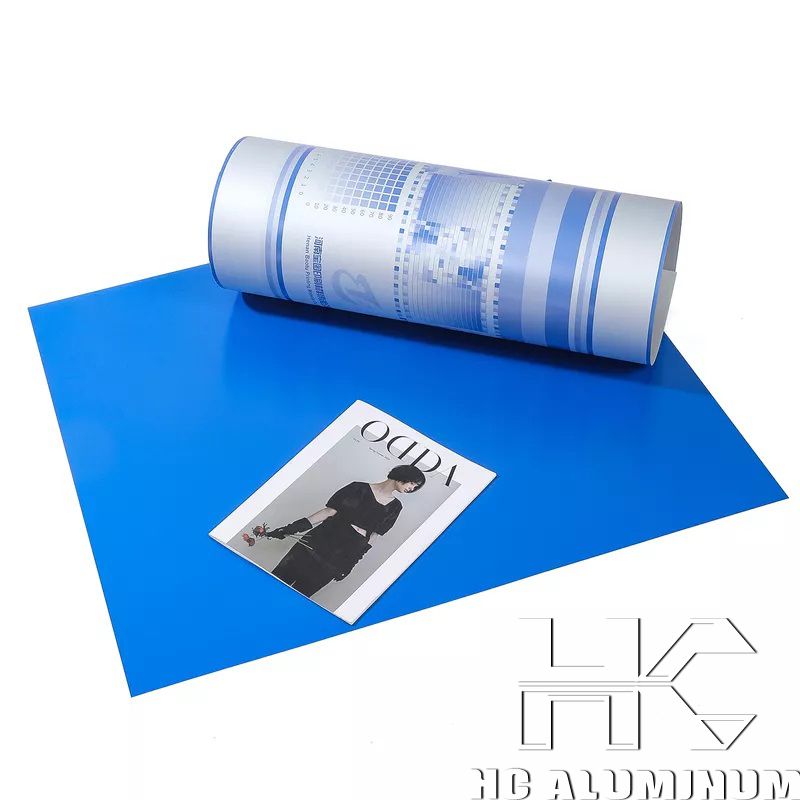

CTP board substrate

Double-layer thermal CTP plate base:

The double-layer thermal CTP plate base uses 1050, 1060, 1050A aluminum alloy, with characteristics such as no need for baking, extremely fast photosensitivity, perfect resolution, stable imaging, and ultra-high durability. It is a new innovative plate material and the preferred plate material for high-end printing.

Technical parameters for thermal CTP plate aluminum plate:

| Alloy | 1060, 1050, 1050A, etc |

| Temper | H18 |

| Thickness | 0.1-0.5mm |

| Width | 400-1600mm |

| Length | Customizable |

| Application | Positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate |

Advantages of using series 1 aluminum plate for thermal CTP plate:

Aluminum content of ≥99.50%, ≥99.60%, ≥99.70%, with the advantages of low density, high strength, moderate wear resistance, good formability, high stability, good surface treatment, etc.

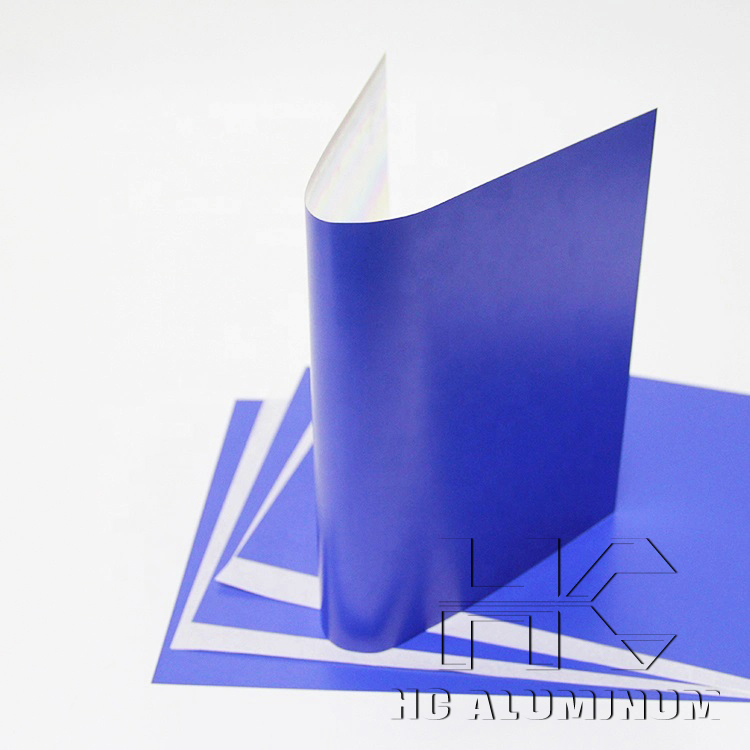

Requirements for using series 1 aluminum plate for thermal CTP plate:

1.The aluminum plate surface must be clean, flat, without cracks, corrosion pits, spots, air holes, scratches, bends, print marks, peeling, loosened branching patterns, oil marks, etc.

2.The edges must be neat, without cracks or burrs.

3.The average roughness value Ra of the surface must be between 0.17-0.21μm to avoid damage to print quality.

4.Thickness tolerance allowed is ±0.003mm, width tolerance is ±0.5mm, length tolerance is 0 to +1mm, side curvature <0.2mm, diagonal deviation <2mm.

Packaging

15mm: 100 pieces/box, 0.30mm: 50 pieces/box, then 50 packs or 1.4 meters high placed on a pallet. A 20-foot container can accommodate 30,000 square meters.