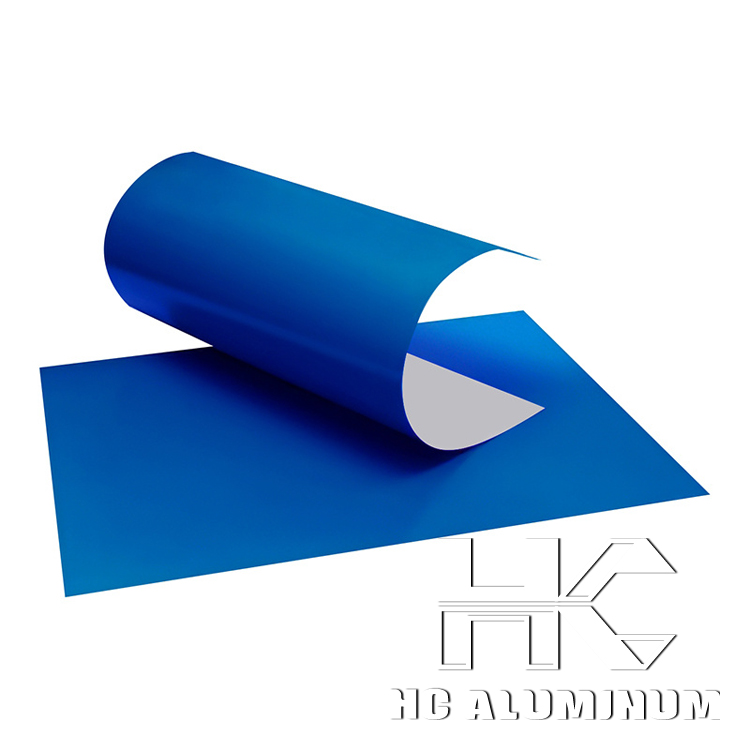

The double layer CTCP plate is a type of plate material used in computer-to-plate (CTP) technology. It is composed of two layers of different coating materials that together control the absorption of ink to improve printing quality. It has a unique double layer coating structure and a range of significant technical features.

The double layer coated positive CTCP plate has high sensitivity, good developing latitude, excellent resolution, consistency, chemical resistance, and printing effect without the need for baking.

CTP board substrate

The base of the double layer CTCP plate is typically made of 1 series aluminum alloy, including products like 1050 aluminum plate, 1050A aluminum plate, 1060 aluminum plate, 1070 aluminum plate, with the main state being H18 and a thickness range of 0.15-0.4mm to ensure stability and durability of the plate material.

Specification

Technical parameters of the double layer coated CTCP plate:

| Plate type | Positive CTCP plate (double layer coated) |

| Substrate | Electrochemical grained and anodized lithographic aluminum base |

| Material | Aluminum |

| Aluminum alloy | Standard 1050 alloy |

| Coating | Infrared sensitive, positive type light |

| Thickness | 0.15, 0.20, 0.25, 0.30, 0.40 (mm) |

| Width | 100-1600mm |

| Print run | 100,000-150,000 impressions |

| Usage | High-quality commercial and newspaper printing |

| Packaging | Optional standard packaging methods, including naked packaging, such as APL packaging |

| Storage and handling | Store in a cool, dry environment, away from extreme cold, heat, or humidity |

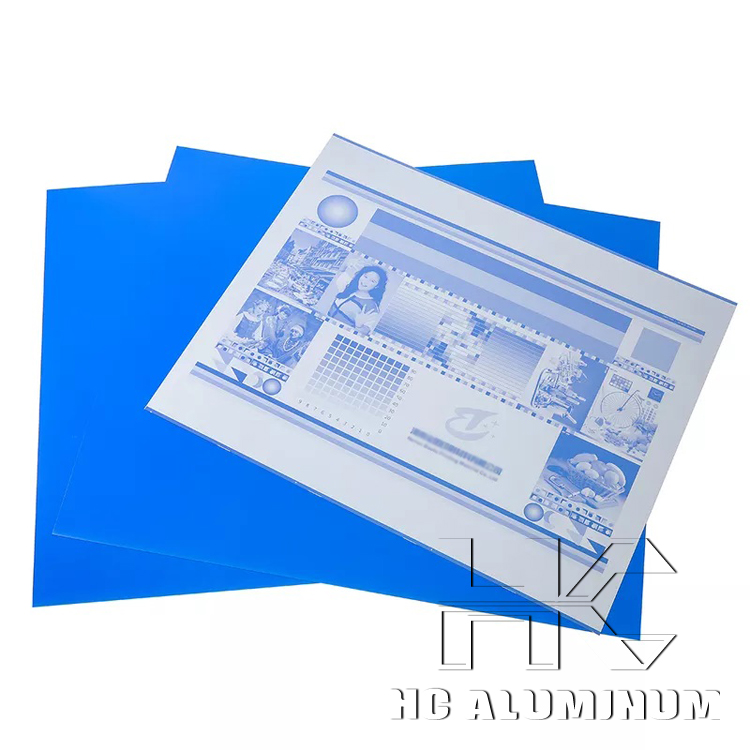

Application

Commercial printing:

1.Commercial Printing:The positive CTCP plate (double layer coated) is widely used in high-quality commercial color printing, such as brochures, posters, packaging, etc.

2.Newspaper printing: Also suitable for newspaper printing to meet high-speed, efficient printing needs.

3.Book printing: Can also be used for book printing to provide stable printing quality and an efficient plate-making process.

Advantages of the double layer coated positive CTCP plate:

1.Reduce the use of coating materials, reduce pollution, and meet environmental requirements.

2.Double layer coating improves printing quality and reduces costs.

3.Excellent hydrophilicity, good ink-water balance

4.Sensitivity

Packaging

0.15mm 100 sheets/box, 70 boxes/pallet

0.30mm 50 sheets/box, 35 boxes/pallet