If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

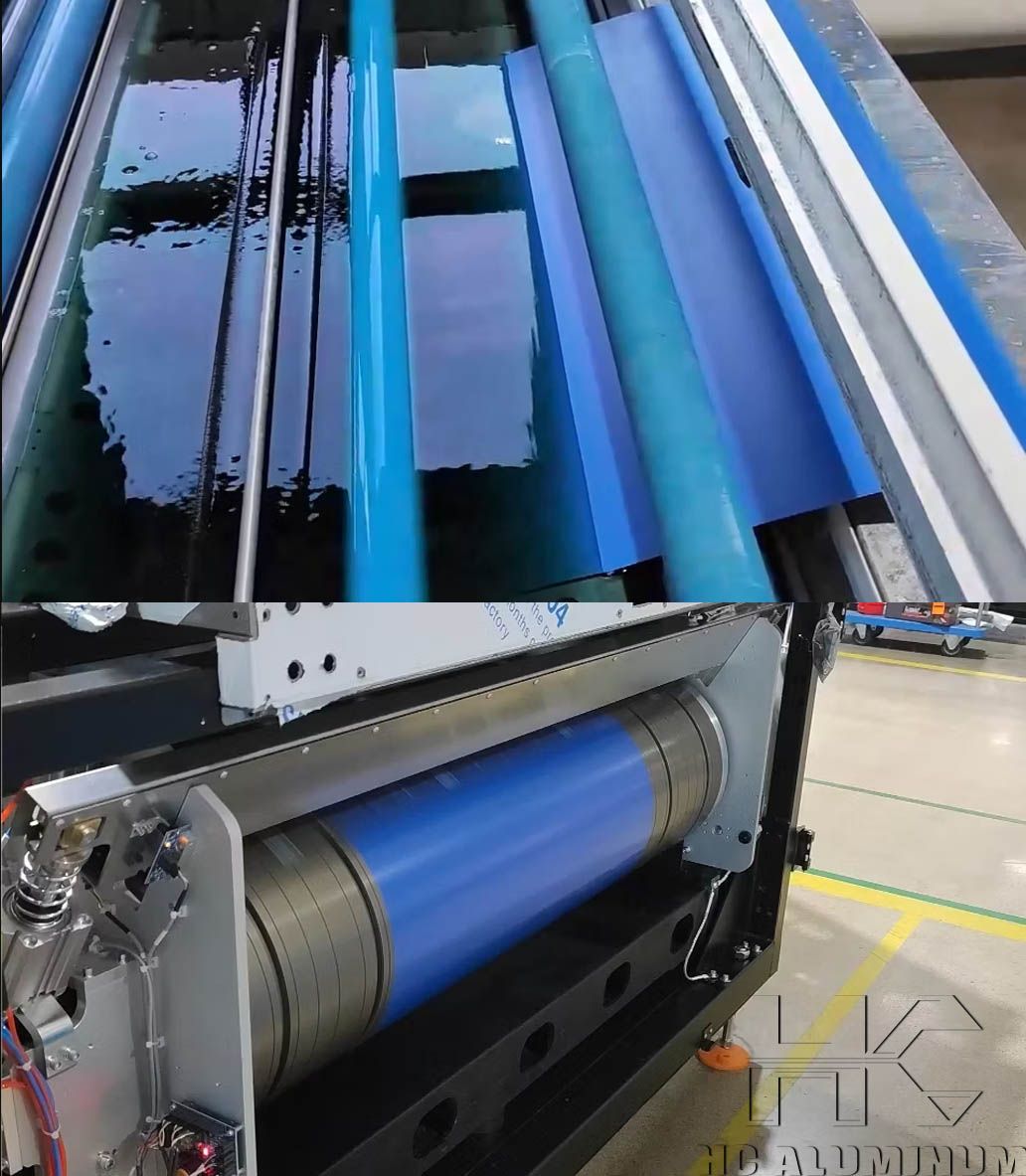

Aluminum offset thermal CTP plate

Aluminum offset thermal CTP plate is a modern platemaking technology for offset printing. Its core is to transfer digital printing files directly to the printing plate of aluminum substrate without the need for traditional film intermediate medium. This technology is widely used in commercial printing, packaging printing and publishing industries.

Aluminum substrate material:

Adopt high-purity aluminum alloy (usually containing a small amount of magnesium, silicon and other elements), such as 1050 aluminum alloy, 1060 aluminum alloy, 1070 aluminum alloy, etc., after stretching, rolling and anodizing, so that its surface finish is high, thickness is uniform and corrosion-resistant. Aluminum substrate has excellent pressure resistance and dimensional stability, and can withstand the mechanical pressure of high-speed printing presses.

Features:

1. High printing quality: Aluminum offset thermal CTP plate has excellent printing quality, which can present delicate and clear images and text.

2. Strong printing durability: The plate has a high printing durability, which can meet the needs of large-scale printing and reduce production costs.

3. Environmental protection: It is made of environmentally friendly materials, has no pollution to the environment, and meets the environmental protection requirements of the modern printing industry.

4. Easy operation: The thermal CTP plate can be operated in a bright room, which simplifies the plate making process and improves work efficiency.

Requirements for making plates with aluminum plates for thermal CTP plates:

1. Cleanliness: The surface of the aluminum plate must be kept highly clean, free of pollutants such as oil, dust, fingerprints, etc., which helps to ensure a good combination of the photosensitive layer and the aluminum plate substrate.

2. Flatness: The surface of the aluminum plate should be flat and smooth, and no cracks, corrosion pits, vents, scratches, folds, marks, peeling, pine branch patterns, oil marks and other defects are allowed. The gap between the unfolded surface and the plane of the aluminum coil, the number of waves, cracked edges, burrs, etc. must also meet the specified requirements.

3. Color and gloss: The surface of the aluminum plate is not allowed to have slight color difference, bright strips and other problems to ensure the color consistency and stability of the printed product.

4. Grain uniformity: The graining treatment on the aluminum plate surface should be uniform to ensure uniform bonding between the photosensitive layer and the aluminum plate substrate and avoid peeling or falling off.

5. Surface roughness: The roughness of the aluminum plate surface needs to be controlled within a certain range to ensure good bonding between the photosensitive layer and the aluminum plate substrate and the clarity of the printed matter.

Website: https://www.printarea-plate.com/a/aluminum-offset-thermal-ctp-plate.html

Keyword: Aluminum alloy thermal ctp plate aluminum substrate

Previous: Blue thermal CTP printing plate