If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

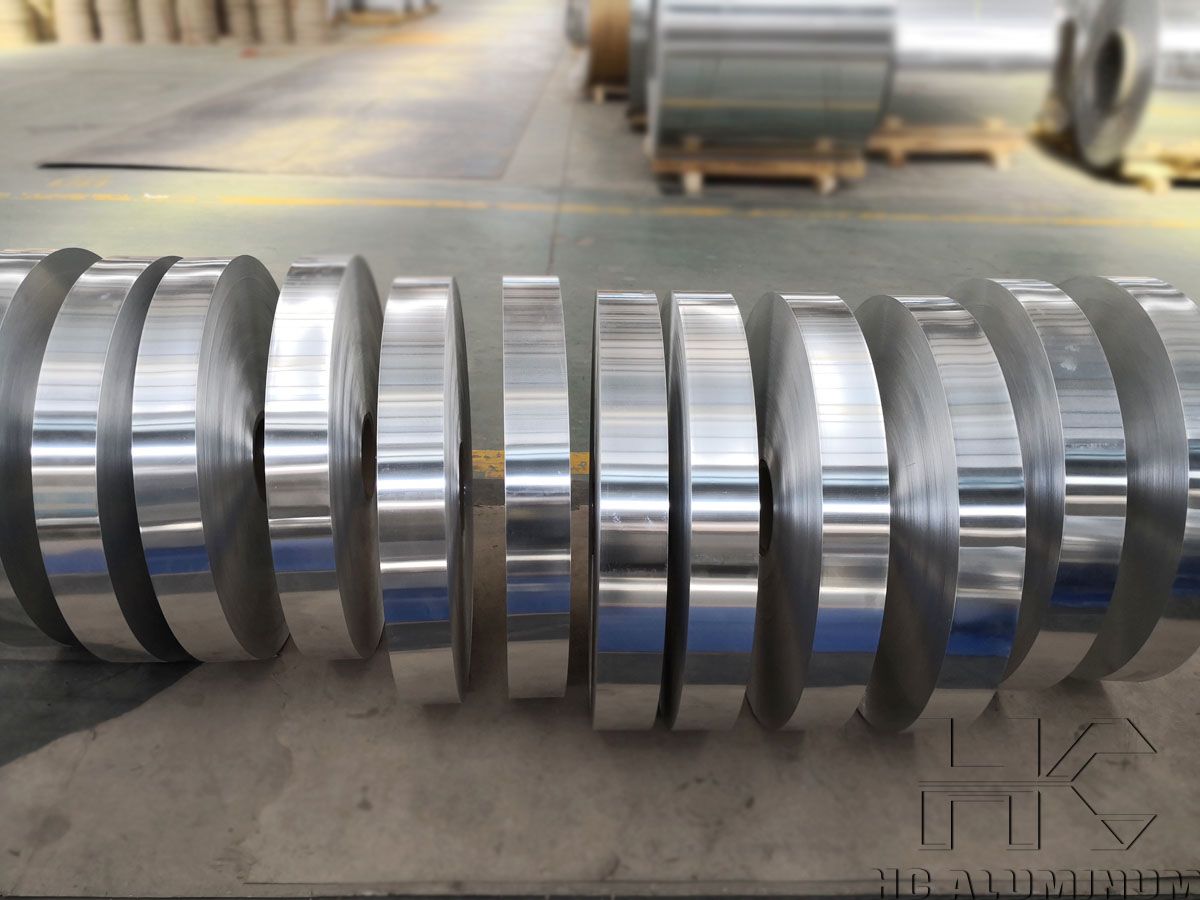

Aluminum strip for computer direct typesetting printing plate

Aluminum strip is a special aluminum-based material dedicated to the printing industry, mainly used to make printing plates for computer direct platemaking (CTP, Computer-To-Plate) technology. This kind of aluminum strip plays an important role in the modern printing industry.

Aluminum strip usually uses alloys such as 1050 and 1060. These alloys have the advantages of high aluminum content (≥99.50% and ≥99.60% respectively), low density, high strength, easy forming, high stability and good surface treatment. It is processed by electrolytic grinding, anodizing and other processes, and a layer of photosensitive material is coated on the surface for CTP printing.

Specifications:

| Alloy | 1050/1060, etc. |

| Temper | H18 |

| Thickness | 0.13-0.40mm |

| Width | 680-1240mm |

| Length | customized according to customer needs |

| Application | positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates. |

Mechanical properties of 1 series aluminum strip:

| Alloy | Tensile strength (normal temperature) | Tensile strength (baked plate) | Elongation after fracture |

1050A | 185~215MPA | 125~140MPA | >1% |

| 1060 | 200~230MPA | 125~140MPA | >1% |

Performance characteristics of aluminum strip for printing plate base:

1. High precision and high quality: aluminum strip can ensure high precision and high quality of printing plate.

2. Efficient and fast: CTP technology can greatly shorten the plate making cycle, and aluminum strip can be quickly replaced and adjusted to improve production efficiency.

3. Environmental protection and energy saving: aluminum strip is a recyclable material, and CTP technology can reduce the use of chemicals and wastewater discharge.

4. Durable and stable: aluminum strip has high strength and wear resistance, and can withstand pressure and friction during printing.

5. Strong adaptability: Aluminum strips can adapt to a variety of printing methods and process requirements.

6. Cost-effectiveness: The use of aluminum strips can bring higher economic benefits to enterprises.

Application areas:

Mainly used for lithography (offset printing) plate making, widely used in books, newspapers, packaging and other fields.

CTP technology can directly transfer digital images to the printing plate base through a computer, eliminating the intermediate steps of traditional plate making, and has the advantages of high precision, high efficiency and low pollution.

CTP plate making plate base manufacturing process:

Aluminum smelting and casting: Prepare high-purity aluminum ingots, smelt and cast into aluminum slabs.

Hot rolling and cold rolling: Aluminum plates are hot rolled and cold rolled for multiple times to achieve the required thickness.

Surface treatment: including cleaning, brushing, chemical treatment, anodizing or coating treatment to meet the adhesion requirements of printed coatings.

Cutting and coiling: Cut large aluminum coils into required sizes for the convenience of downstream customers.

Introduction to the appearance requirements of CTP substrate:

The aluminum substrate is required to be clean and flat, without cracks, corrosion pits, spots, vents, scratches, folds, marks, peeling, pine-like patterns, oil marks and other defects; non-metallic indentation and adhesion, horizontal skin, horizontal lines and other defects are not allowed on the surface; slight color difference, bright stripes and other problems are not allowed; there should be no bulges, ruffles and other phenomena.

MC Aluminum CTP substrate uses 1050A aluminum plate and 1060 aluminum plate with good appearance quality and physical and mechanical properties, and has good use effect. When casting CTP substrate, high-quality raw materials are selected, and advanced equipment and professional casting workers are used in the production process. Strictly follow the standards to ensure excellent product quality.