If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

1050A PS aluminum-based sheet

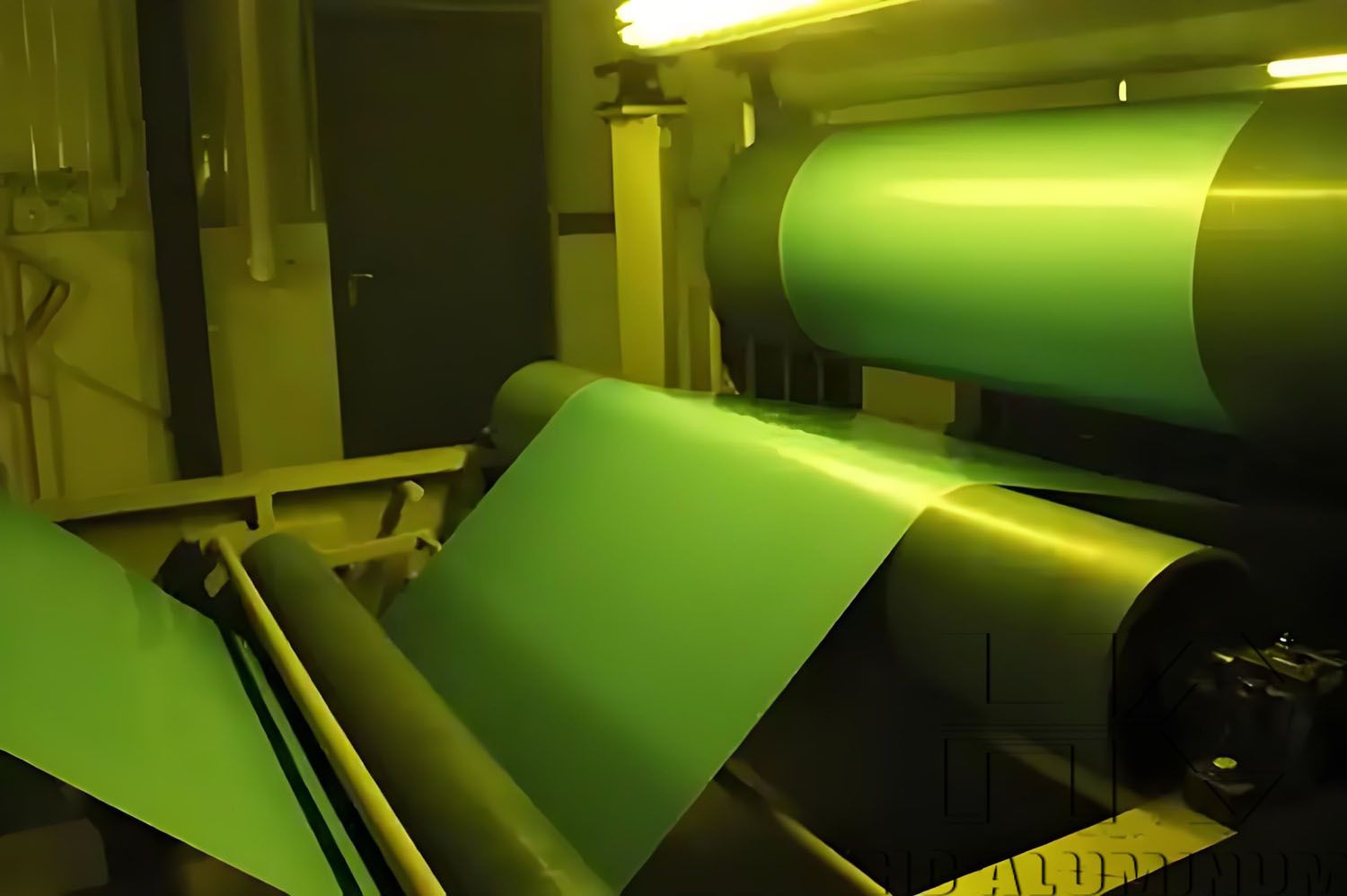

1050A aluminum sheet is a high-purity aluminum alloy material with an aluminum content of about 99.5%, similar to 1050 aluminum sheet, but with slightly higher purity and more stable performance. It is often used as a PS (Presensitized) plate substrate and is a common choice in the printing industry.

1050A alloy introduction:

1050A aluminum sheet belongs to the 1 series pure aluminum sheet, with an aluminum content of ≥99.50%, and a small amount of other elements are added to improve its performance. This alloy has the advantages of low density, high strength, moderate wear resistance, good formability, good hydrophilicity, and high stability.

1050A aluminum alloy physical and mechanical properties:

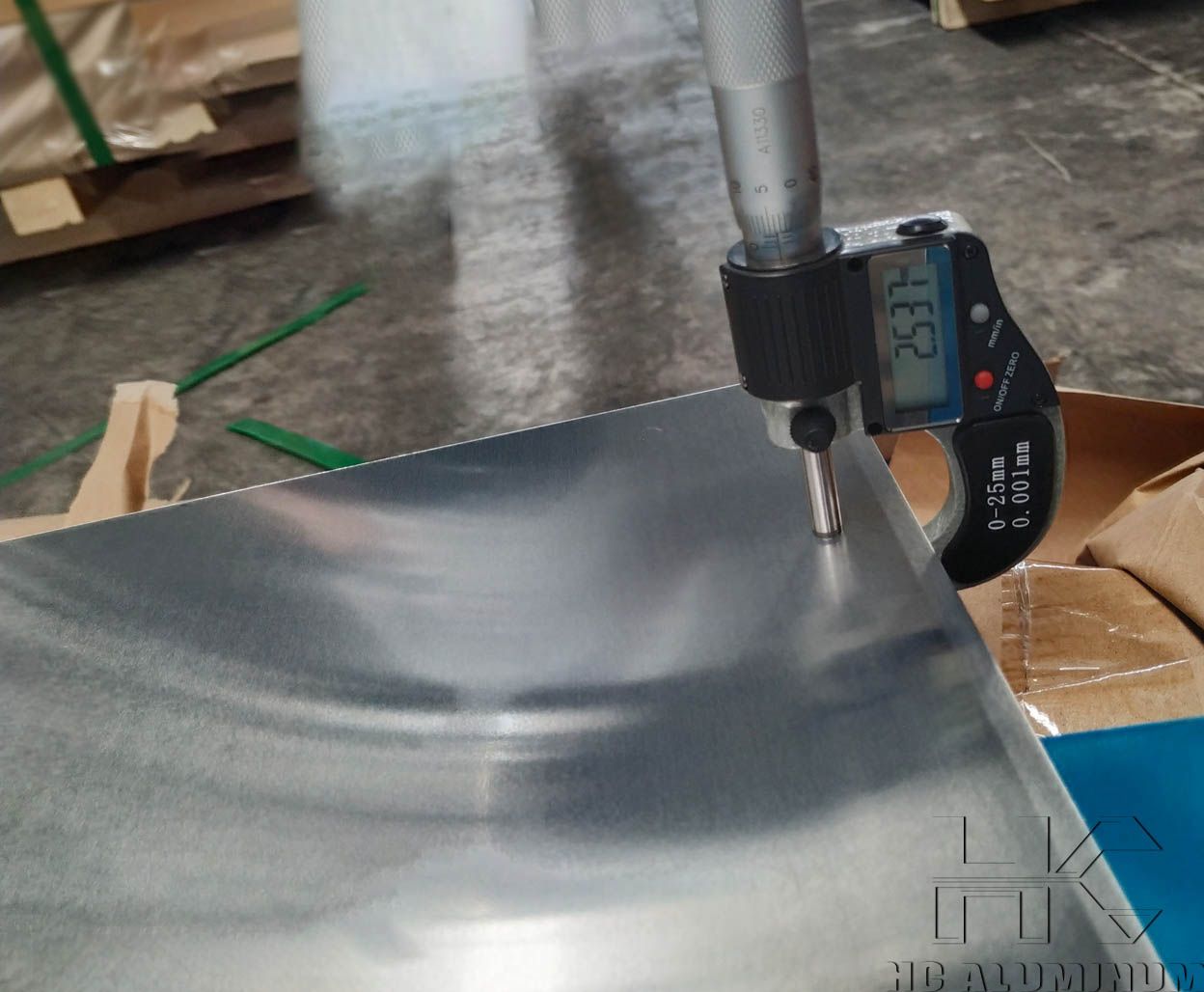

1050A aluminum sheet has good physical and mechanical properties, such as tensile strength, elongation after fracture, etc., which make it an ideal material for PS plate base. Its tensile strength is between 185-215MPa. After the baking plate treatment, the tensile strength will be reduced, but it still remains in the range of 125-140MPa. The elongation after fracture is greater than 1%, indicating that the material has good plastic deformation ability.

PS aluminum plate base specifications:

| Alloy series | 1 series |

| Alloy | 1050A |

| Temperature | H18 |

| Thickness (mm) | 0.13-0.40 |

| Width (mm) | 400-1600 |

| Length (mm) | C |

| Inner diameter (mm) | 305/405/505 (according to customer requirements) |

| Application | positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates. |

1050A chemical composition:

| Chemical composition (%) | ||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | |

| Single | Total | |||||||||||

| 1050A | 0.25 | 0.04 | 0.05 | 0.05 | 0.05 | - | 0.07 | 0.05 | - | 0.03 | - | 99.5 |

In PS plates, 1050A aluminum plate has the following advantages as a substrate:

1. Excellent corrosion resistance: high aluminum content makes it resistant to chemical solvent corrosion and prolongs service life.

2. Good ductility and formability: the material is soft and easy to process into thin plates, ensuring stability and imaging consistency.

3. Smooth and uniform surface: after polishing and anodizing, the surface is flat and defect-free, improving the accuracy of image transfer.

4. High thermal conductivity and electrical conductivity: good heat dissipation performance helps to increase the ink drying speed.

Surface quality requirements of 1050A aluminum plate for PS plate base:

The surface quality of 1050A PS aluminum plate substrate is crucial to the printing effect. Its surface should be flat, smooth, free of cracks, bubbles and other defects. In order to obtain better printing effects, it is usually necessary to perform surface treatment on the aluminum plate substrate, such as anodizing, electrolytic grinding, etc. These treatments can improve the wear resistance, corrosion resistance and hydrophilicity of the aluminum plate substrate, thereby improving the printing performance and life of the printing plate.

The 1050A aluminum plate, 1060 aluminum plate and other aluminum plates for PS/CTP plate base produced by Hongchang Aluminum have smooth surface, high cleanliness, good use effect and excellent product quality. They are exported to many countries and regions overseas, with a market share of more than 50% and are deeply favored by users.

Website: https://www.printarea-plate.com/a/1050a-ps-aluminum-based-sheet.html

Keyword: 1050A aluminum sheet PS/CTP plate base PS aluminum plate base

Previous: Hot-rolled aluminum sheet for CTP plate