What is a thermal CTP plate?

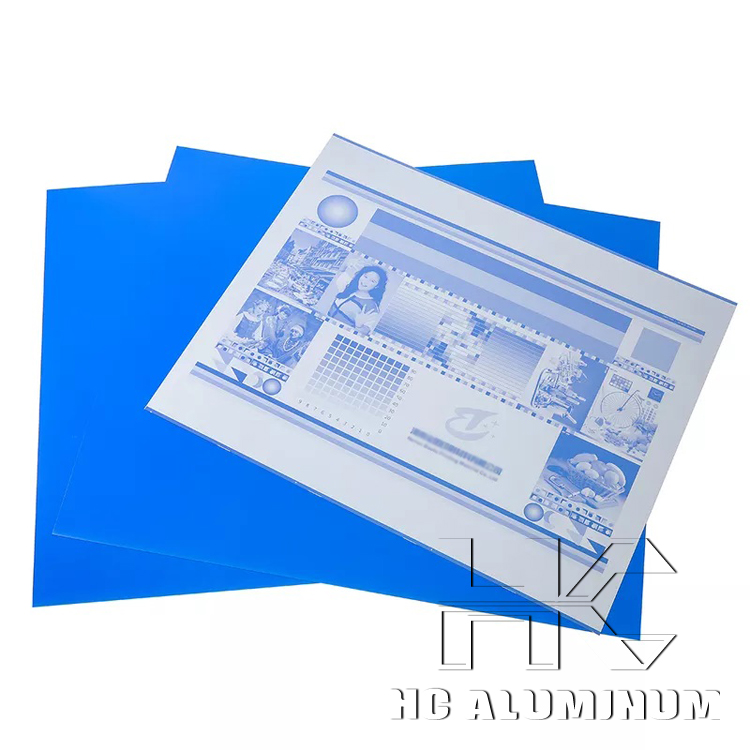

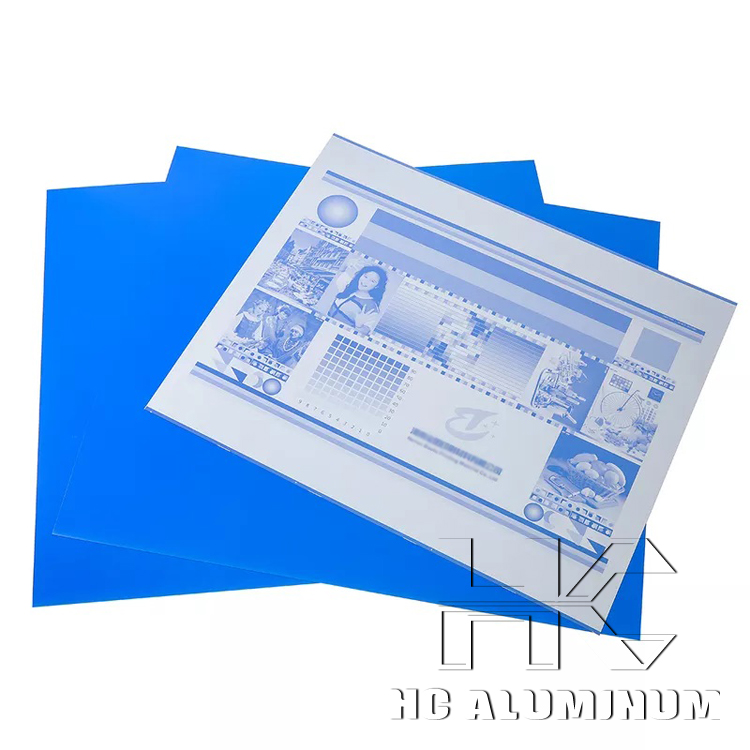

Single-layer thermal CTP plate (Computer-to-Plate) is a printing plate made using the characteristics of thermal sensitive materials and CTP technology, using 1-series aluminum alloy as the base, including 1050 aluminum alloy, 1050A aluminum alloy, 1060 aluminum alloy, etc.

Working principle

Working principle of thermal CTP

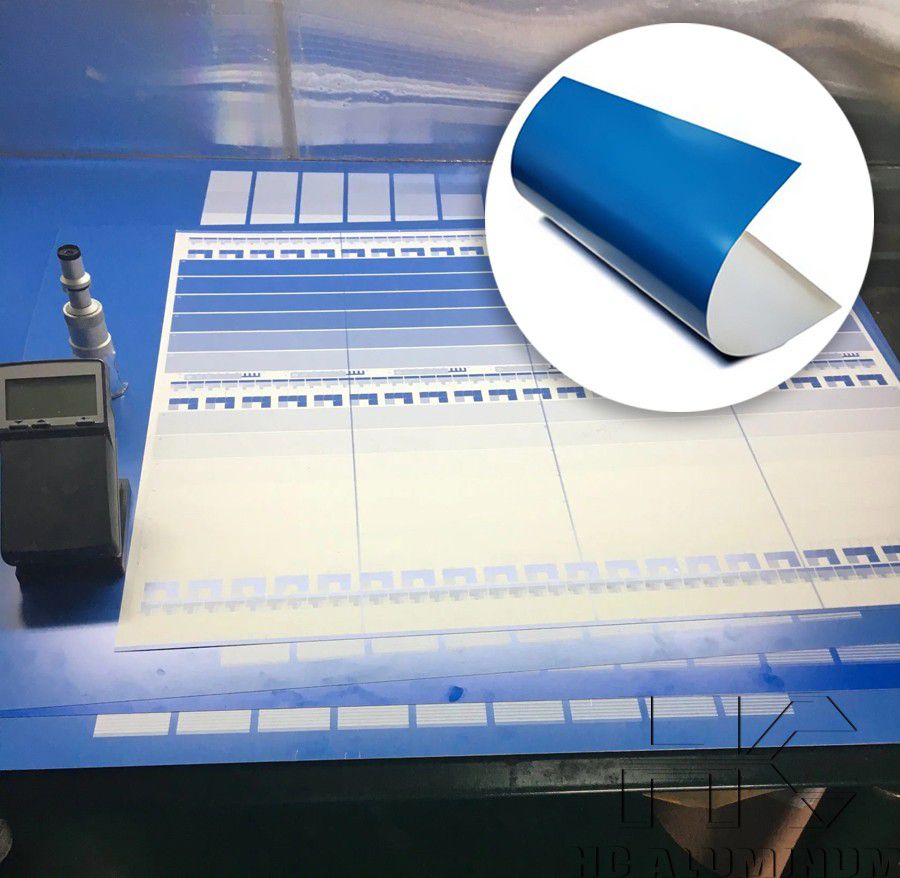

By using the characteristics of thermal sensitive materials, the digital image is directly transferred to the surface of the printing plate under the action of the heating by the print head. Typically, the print head releases heat energy on the printing plate based on the signal of the digital image, causing the thermal sensitive material to change color locally, forming the pattern and text of the image.

Applications

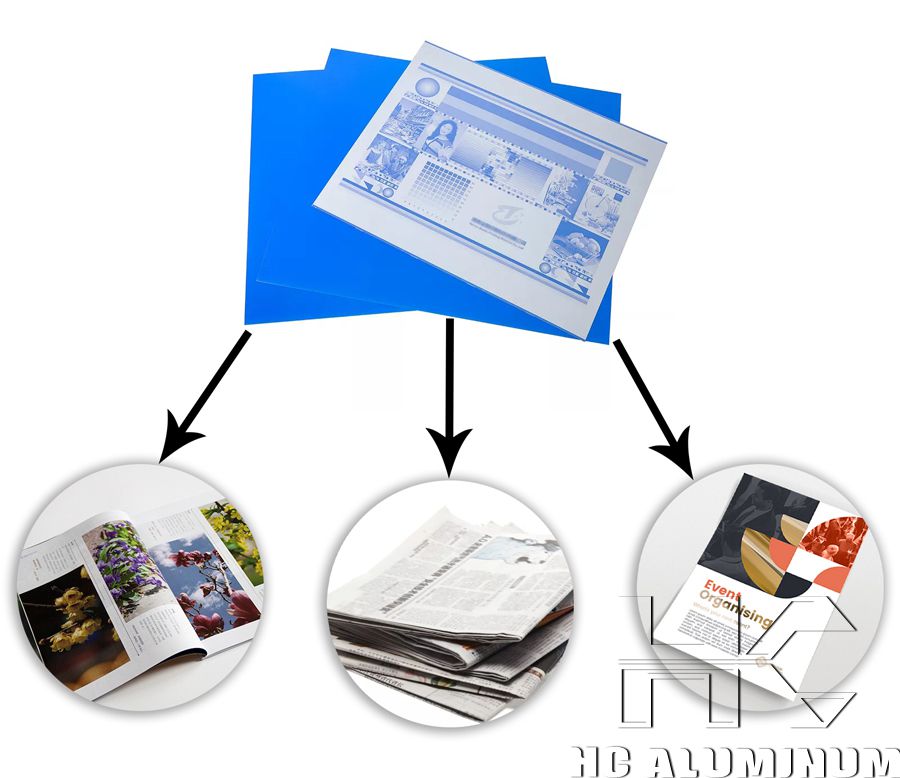

Applications of thermal CTP plates:

Positive thermal CTP plates can meet the requirements of a variety of high-end commercial color printing, newspaper printing, magazine printing, and packaging box printing. Thermal CTP plates have the advantages of fast plate making speed, high tolerance, accurate dot reproduction, excellent ink balance, and high durability.

Features:

Thermal CTP plate technology features:

1.Good dot reproduction, high resolution, and sharp and clear dot edges

2.Good printing adaptability

3.Low sensitivity to natural light, can be operated in daylight conditions

4.High tolerance in development, easy to operate

5.Environmentally friendly and energy-saving

6.Digital production, reducing plate making costs, improving printing quality stability and consistency.

7.Excellent hydrophilicity, maintaining optimal water-ink balance

Printing has high overall requirements for plate materials, usually using high-quality aluminum plate materials such as 1050 aluminum plate, 1050A aluminum plate, 1060 aluminum plate, etc., with advantages of low density, high strength, good formability, good hydrophilicity, high stability, good surface treatment, etc., to ensure the quality of printed products.

Specifications

Thermal CTP plate technical parameters:

Product typ | Single-layer thermal CTP plate |

Application type | High grade commercial and newspaper printing |

Thickness | 0.15mm,0.20mm,0.25mm,0.30mm,0.40mm |

Max width | 1350mm |

| Spectral sensitivity | 830nm |

| Exposure energy | 110~130mj/Cm2 |

| Developing temperature | 22-28℃ |

| Resolution | 1~99% at 200lpi |

| Developing time | 25-35sec |

| Safety-light | 2hours under white light |

| Run length | Unbaked: 50 000 - 100 000 impressions |

| Baked | more than 100 000impressions |

| Shelf time | 18 months |

| Trademark | HONGCHANG or customized |

| Transportation Package | Export standard, seaworthy package |

| Specification | 0.15mm 100PCS/box;0.25mm 50PCS/box;0.30mm 50PCS/box; 0.40mm 30 PCX/box; customized. |

| HS code | 37013024 |

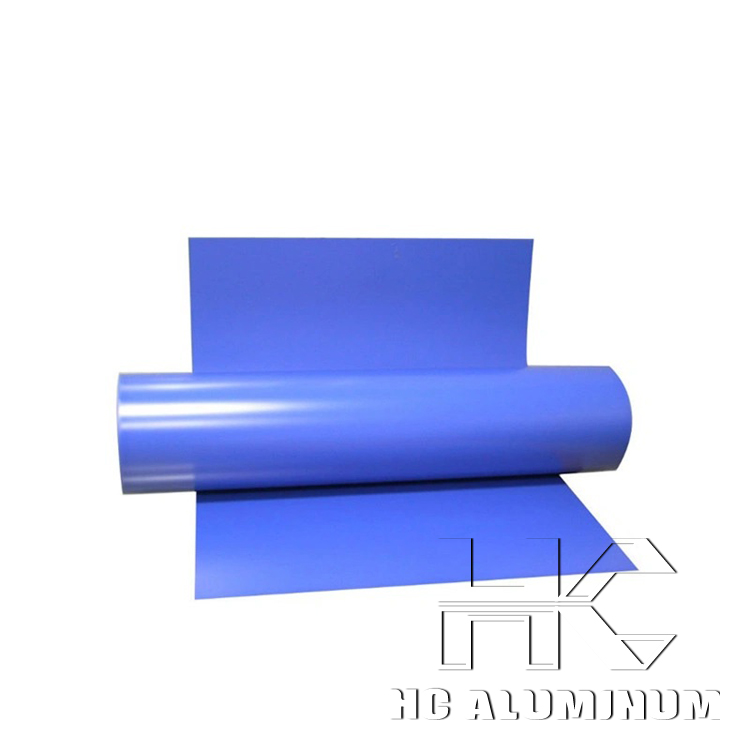

Thermal CTP plate aluminum plate specifications:

| Alloy | 1060, 1050, 1050A |

| Temper | H18 |

| Thickness | 0.1-0.5mm |

| Width | 400-1600mm |

| Length | Customized |

| Application | Positive PS plate, Thermal CTP plate, Photosensitive CTP plate, UV-CTP plate |

Thermal CTP plate aluminum plate size deviation:

| Thickness tolerance | ±0.003mm |

| Width tolerance | ±0.5mm |

| Length tolerance | Error of 0 to +1mm |

| Side curvature | <0.2mm |

| Diagonal tolerance | <2mm |

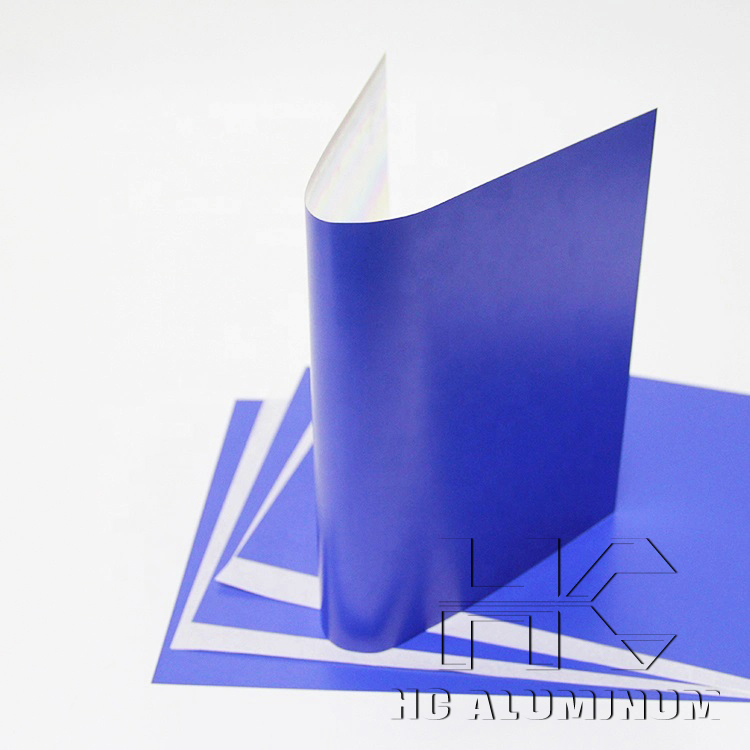

High surface quality requirements for Thermal CTP plate aluminum plate:

1.Clean and flat:The aluminum plate surface must be clean and flat, free of cracks, corrosion pits, dots, air holes, scratches, creases, marks, peeling, loose branch-like patterns, oil stains, etc.

2.No defects: The surface must not have non-metallic indentations and adhesions, scabs, cross-grain, etc.

3.Color consistency: No slight color difference, bright bars, etc.

Packaging

1.Good packaging to prevent damage to goods:

15mm, 100pcs/pkg 0.2mm, 50pcs/pkg 0.25mm, 50pcs/pkg 0.3mm, 50pcs/pkg

Plate-plastic cover-carton (wooden stick edges)-wooden pallet-hard carton cover-plastic cover

2.Samples

In order for our customers to better understand our quality, we provide 8-10 samples free of charge, with shipping costs paid upon delivery.