If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

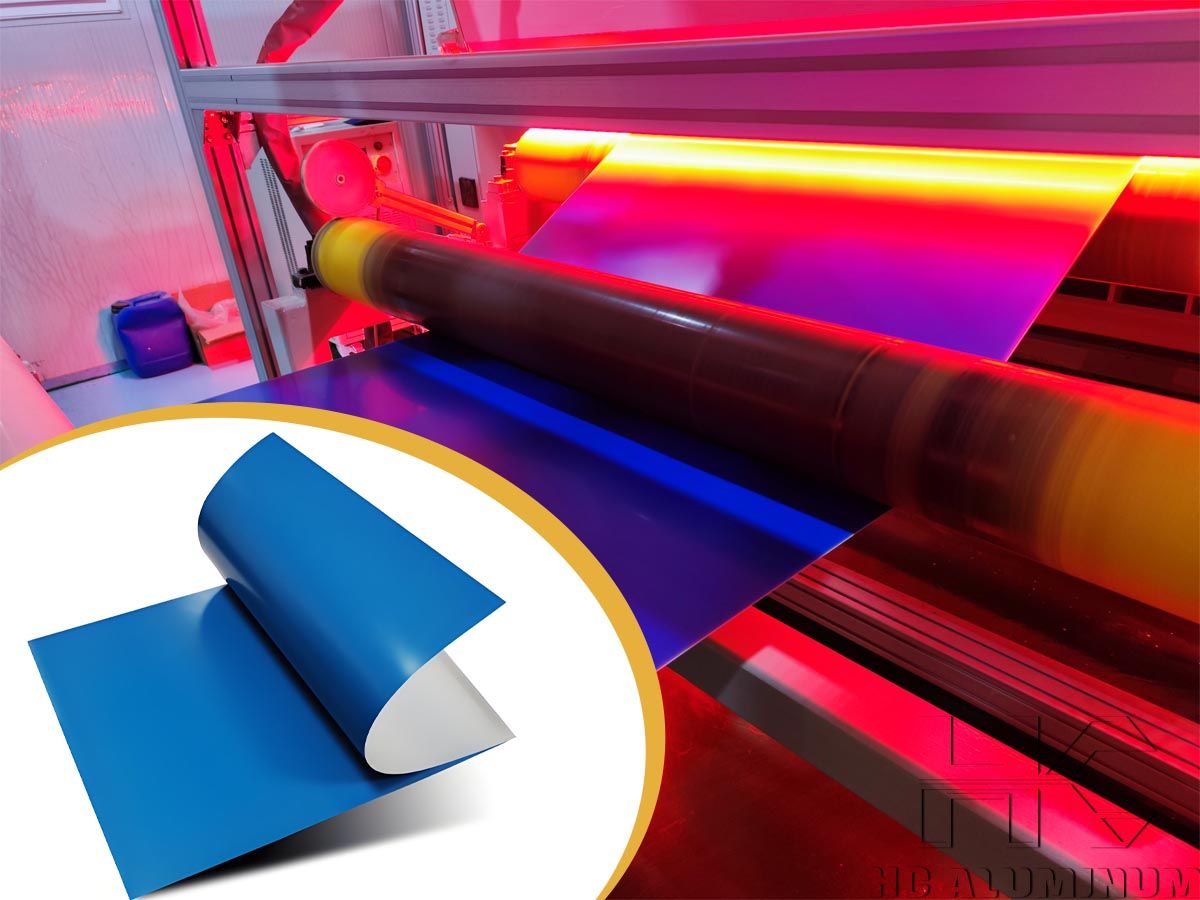

High Sensitivity Positive Thermal CTP Plate

The imaging process of thermal CTP plates begins with an "energy interaction" between an infrared laser (typically around 830 nm) and the infrared-absorbing dye in the heat-sensitive layer of the plate. The dye instantly converts light energy into thermal energy, triggering localized physical or chemical changes. Thermal CTP plates can be classified into two types:

Negative Thermal CTP Plates:

In the heated areas, a crosslinking reaction occurs, making the molecular structure stronger and insoluble during development. These areas remain on the plate and form the ink-receptive image areas.

Positive Thermal CTP Plates (focus of this article):

Using an 830 nm infrared laser, the heat-sensitive coating on the aluminum substrate is scanned and exposed. In the heated areas, a decomposition reaction occurs: molecular bonds in the coating break under thermal energy, and solubility increases sharply. During development, these areas are dissolved and removed by the alkaline developer, exposing the hydrophilic aluminum base, which forms the non-image areas. The unexposed regions remain on the plate, forming the ink-receptive image areas. The entire process resembles a microscopic form of "thermal engraving."

Structure of a Positive Thermal CTP Plate

A high-performance positive thermal CTP plate typically consists of the following layers:

High-Purity Aluminum Substrate

Usually made from 1050 or 1060 aluminum, electrochemically grained and anodized to ensure excellent hydrophilicity and run length.

Heat-Sensitive Coating

Highly sensitive to 830 nm laser exposure, with a uniform coating that delivers sharp image edges.

Protective Layer (Optional)

Enhances scratch resistance during transportation, storage, and plate handling.

Technical Specifications of the CTP Plate

| Plate type | Positive thermal CTP plate |

| Spectral sensitivity | 830 nm |

| Exposure energy | 110 - 130 mJ/cm² |

| Substrate material | High-purity electrochemically grained aluminum |

| Common aluminum grades | 1050 / 1060 |

| Plate thickness | 0.15 / 0.20 / 0.25 / 0.30 mm |

| Resolution | 1 - 99% (200 lpi or higher) |

| Screen type | AM / FM |

| Development | Positive development |

| Developer temperature | 23 ± 2 °C |

| Development latitude | Wide |

| Run length | 100,000 - 150,000 impressions (unbaked) |

| Compatible equipment | Mainstream 830 nm thermal CTP devices |

| Storage conditions | 18-25 °C, humidity ≤ 65% |

Core Technical Advantages of Positive Thermal CTP Plates

1.Exceptional dot quality

Thanks to minimal thermal diffusion, image edges are extremely sharp, enabling precise reproduction of 1%–99% dots at 200 lpi or even higher, easily meeting the demands of high-definition printing.

2.Outstanding stability

Heat is the sole triggering factor. The plate is insensitive to ambient stray light, allowing daylight handling. Moreover, the plate remains highly stable before exposure, requires no preheating, and is convenient for storage and transportation.

3.Strong production adaptability

High sensitivity enables compatibility with a wide range of plate setters, from high-end commercial printers to newspaper web presses. The wide exposure latitude makes the plate less sensitive to fluctuations in development conditions.

4.Excellent press performance

Fast ink acceptance and easy ink–water balance help reduce start-up waste and improve press efficiency.

5.Convenience of Daylight Operation

Thermal technology is insensitive to visible light. This allows operators to load and unload plates under normal indoor lighting conditions, eliminating the need for expensive darkroom environments and significantly optimizing workflow efficiency and workplace comfort.

Typical Applications

Commercial brochures and promotional materials

Newspapers, magazines, and textbook printing

Packaging cartons and label printing

Fast turnaround and short-run printing jobs

Environmental and Process Advantages

Compared with traditional computer-to-film (CTF) plate making, positive thermal CTP technology offers a simplified workflow:

(1)No film required, reducing material consumption

(2)Lower developer usage and easier waste liquid treatment

(3)Support for low-chemistry or processless solutions (for certain models)

Against the backdrop of increasingly strict environmental regulations, high-sensitivity positive thermal CTP plates are more aligned with the future direction of green printing.

Website: https://www.printarea-plate.com/a/high-sensitivity-positive-thermal-ctp-plate.html

Keyword: 830nm thermal CTP plate thermal CTP plate positive thermal CTP plate negative thermal CTP plate CTP plate TP plate manufacturer printing plate manufacturer aluminum substrate 1050 aluminum sheet 1060 aluminum sheet CTP aluminum base