If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

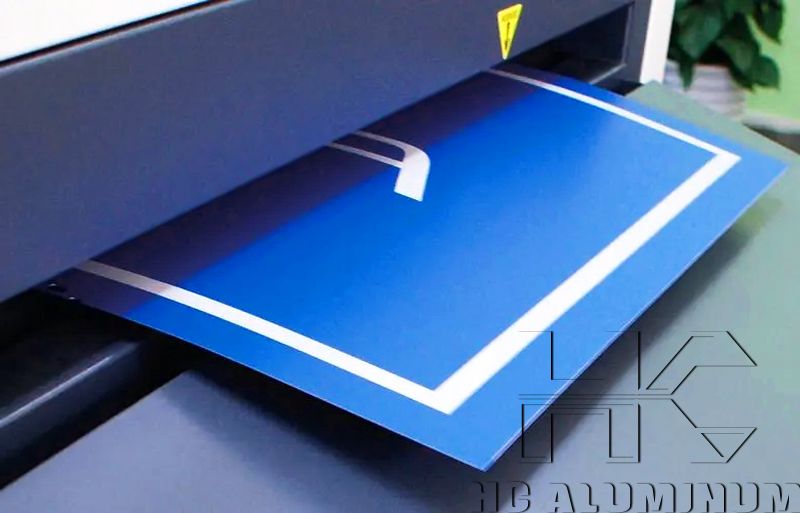

CTP 1050/1060 Aluminum Coil Offset Printing

CTP aluminum plate base is a material used in the printing industry. It is a printing platemaking technology that directly transfers the numbers, pictures or pages edited in the electronic prepress processing system or color desktop system to the printing press without subsequent processing.

1050/1060 CTP plate base advantages:

1050 and 1060 aluminum coils are commonly used for CTP (computer-to-plate) plate bases and are high-end products of PS plates. It has the advantages of high density, high strength, moderate wear resistance, easy forming, good hydrophilicity, and high stability, making it an ideal choice for CTP plate bases.

CTP plate base specifications:

| Alloy | 1050, 1060, 1050A, 1070, etc |

| Temper | H18 |

| Thickness | 0.1-0.5mm |

| Width | 400-1600mm |

| Length | 100-16000mm |

| Application | positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates |

CTP plate base application areas: positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates.

Technical requirements of CTP plate for aluminum coils:

1. Surface quality: CTP plate base requires a clean and flat surface without various defects and flaws, such as cracks, corrosion pits, scratches, etc. The surface is not allowed to have non-metallic indentation and adhesion, horizontal skin, horizontal lines and other defects.

2. Dimensional accuracy: The allowable deviation of thickness is ±0.003mm, the allowable deviation of width is ±0.5mm, and the allowable deviation of length is 0~+1mm. The side curvature is less than 0.2mm, and the allowable deviation of diagonal is less than 2mm.

3. Surface roughness: The average Ra value is between 0.17~0.21μm to ensure the printing quality and effect.

4. Flatness requirements: The aluminum plate is required to have extremely high flatness. Most CTP equipment uses scanning imaging. If the plate flatness is poor, it will affect the quality of laser imaging.