Welcome to HongChang Aluminum CO., LTD.

Visit

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Welcome to HongChang Aluminum CO., LTD.

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

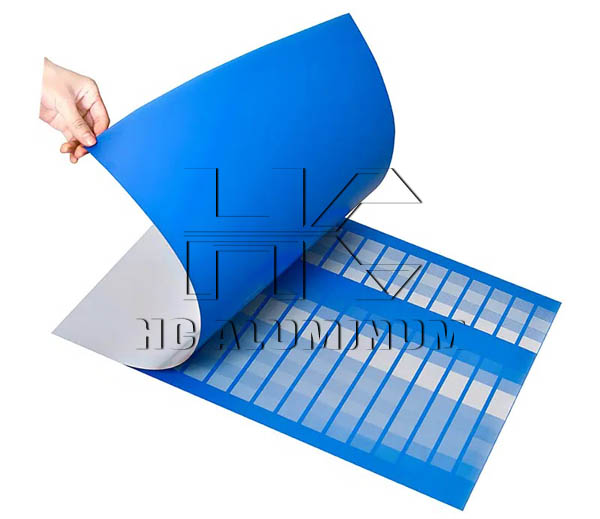

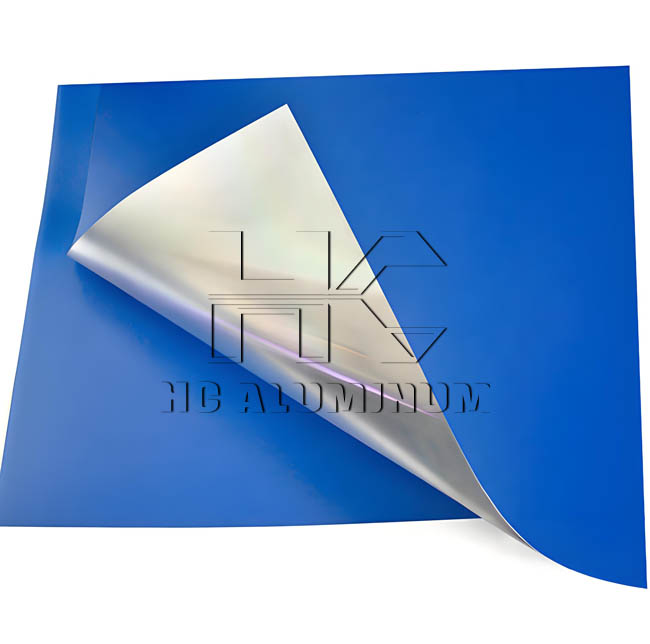

Processless thermal CTP plate is a type of plate material specially designed for computer-to-plate (CTP) technology, featuring significant characteristics such as environmental protection, high efficiency, and high quality.

Double-layer coated thermal CTP plates are usually used for printing jobs that require high quality and efficiency.

CTCP plates are widely used in the printing industry, especially for high-volume commercial printing jobs where speed and quality are crucial.

Thermal CTP plates have the advantages of fast plate making speed, high tolerance, accurate dot reproduction, excellent ink balance, etc., and are widely used in the printing industry.

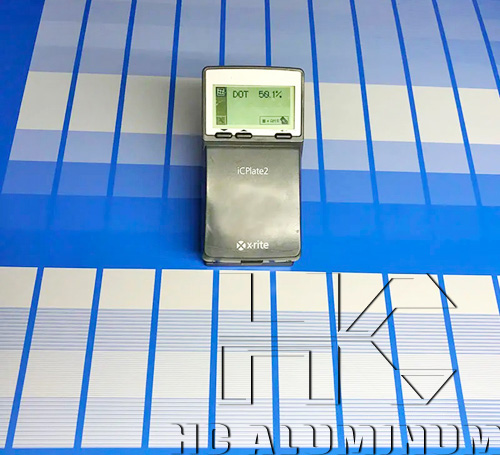

Processless thermal CTP plates use 830 nm thermal imaging technology and require no chemical development, offering high plate-making efficiency and excellent stability, making them ideal for high-volume commercial and packaging printing applications.

In the field of newspaper printing, offset printing technology has become mainstream due to its fast speed, stable printing quality and adaptability to large-scale printing.

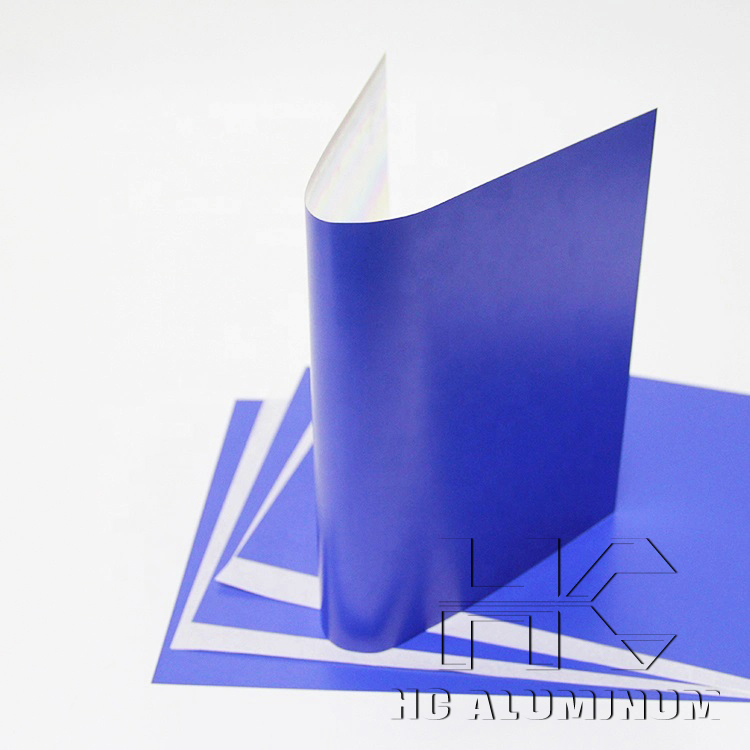

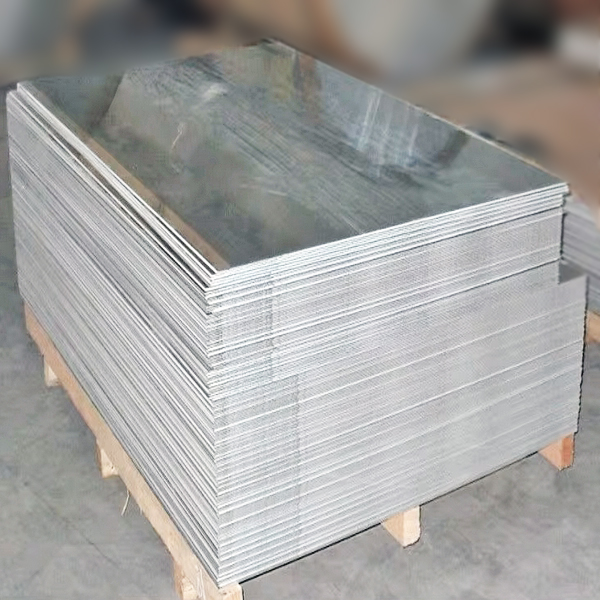

Hot-rolled 1100 CTP aluminum sheet belongs to the pure aluminum sheet series, with relatively low strength, but excellent ductility, formability, weldability and corrosion resistance;

In the printing industry, PS sheet (pre-coated photosensitive sheet) refers to a sheet made by coating a non-silver photosensitive (thermal) resin layer on an aluminum substrate sheet. For photosensitive sheet substrates, 1050, 1060, 1070, 1050A aluminum

Thermal CTP plates are one of the core plate materials used with mainstream printing presses, offering high efficiency, high stability, and high resolution.

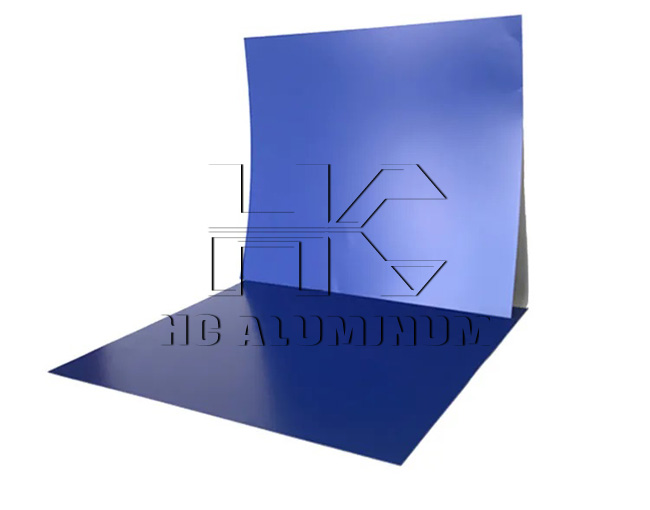

Hongchang's high-quality CTP aluminum substrate uses 1 series high-purity aluminum, which is flat and corrosion-resistant, ensuring high-resolution imaging and stable printing strength, and is widely used in the digital printing industry.

The aluminum plates used in printing houses are mainly PS plate aluminum plate base and CTP plate aluminum plate base, generally made of 1050, 1060, 1070 and other aluminum alloy materials.

Hongchang Aluminum focuses on the research and development and production of offset printing plates. Its products cover offset printing plates, thermal CTP plates, and raw material aluminum substrates, and are widely used in books, packaging and other fie

1-Series photopolymer plate aluminum substrates are made from 1050, 1050A, 1060, and 1070 aluminum sheets as the supporting material for photopolymer plates (such as PS plates and CTP plates).

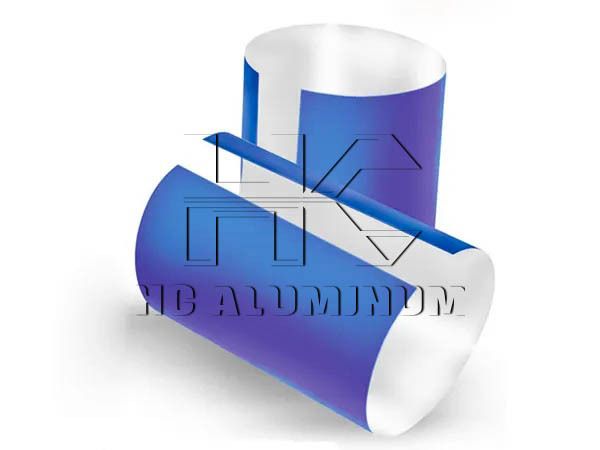

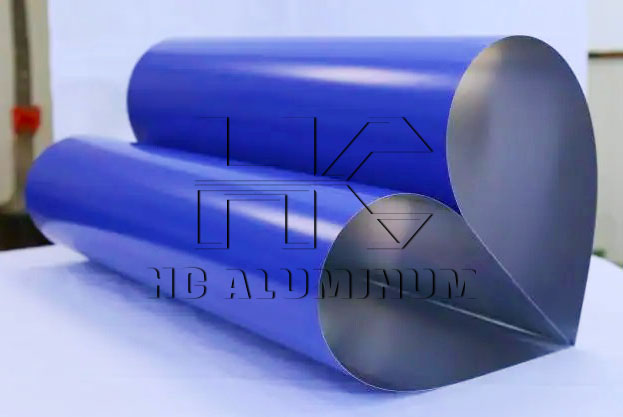

The main raw material for CTP plates is the printing plate material, which is typically made from aluminum base plates (also called aluminum plates) that are treated with a coating to accept image transfer.

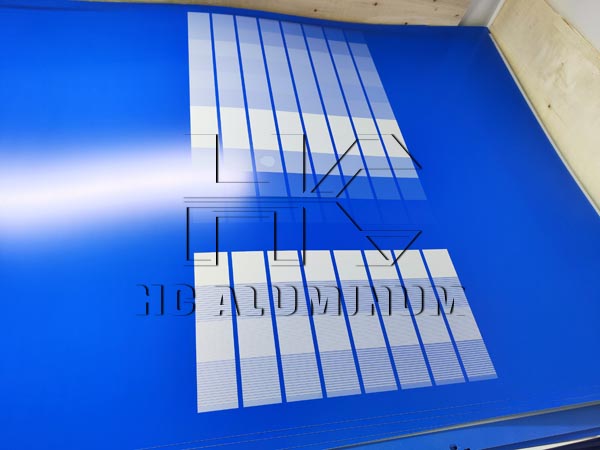

High sensitivity positive thermal CTP plates with excellent dot reproduction, stable imaging performance, and wide exposure latitude.Suitable for commercial and packaging offset printing.

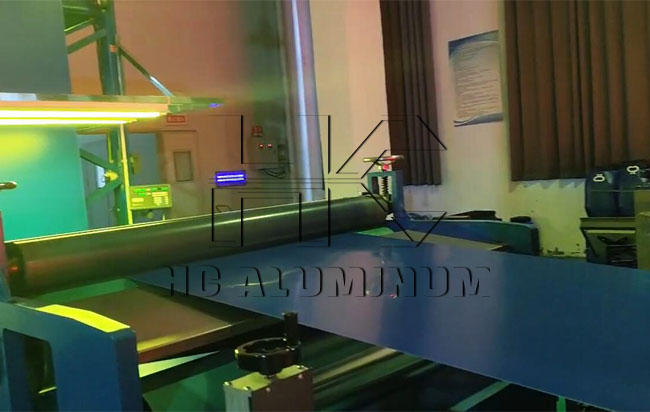

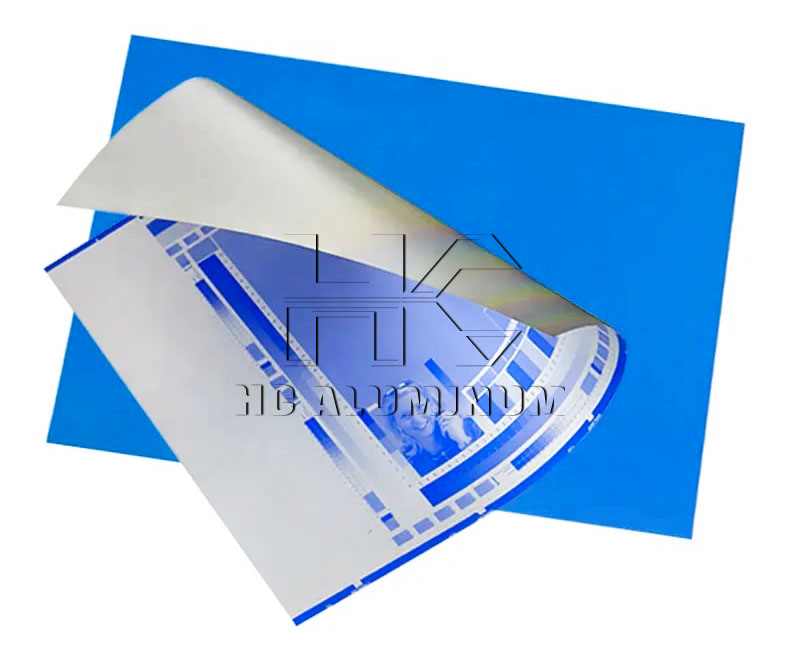

Aluminum offset thermal CTP plate is a modern platemaking technology for offset printing. Its core is to transfer digital printing files directly to the printing plate of aluminum substrate without the need for traditional film intermediate medium.

Offset printing is commonly used in newspaper production, with PS plates (Presensitized Plates) or CTP plates being the primary materials.

1350mm CTP plates, featuring high stability, durability, and excellent photosensitivity, are widely used in high-end printing applications. Available in a variety of custom sizes, they help printing companies improve efficiency and quality.

The CTCP plate produced by HONGCHANG Aluminum is renowned for its high resolution, superior quality, excellent compatibility, and cost-effectiveness.

1050A aluminum sheet is a high-purity aluminum alloy material with an aluminum content of about 99.5%, similar to 1050 aluminum sheet, but with slightly higher purity and more stable performance.

CTP plates primarily use aluminum plates, which not only improves printing efficiency but also reduces plate-making costs.

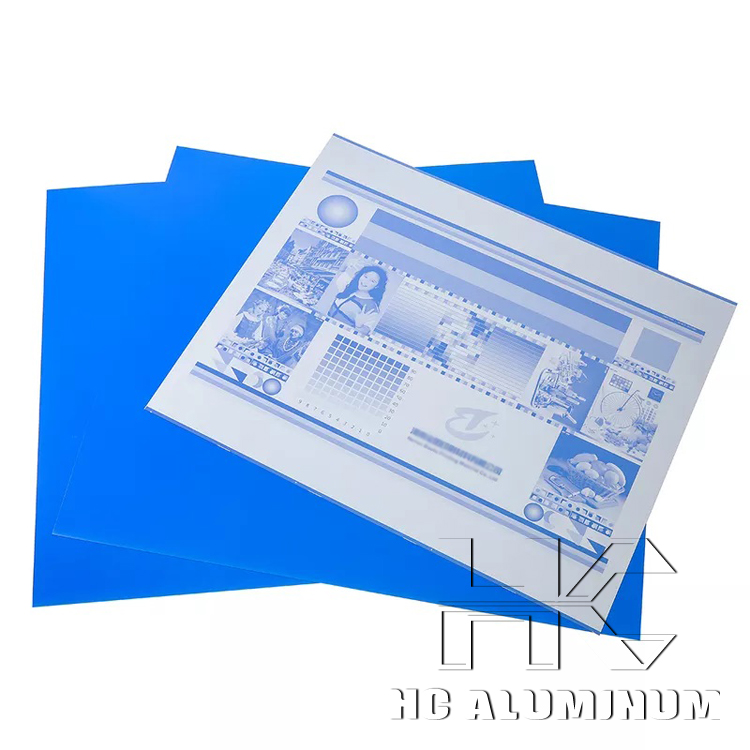

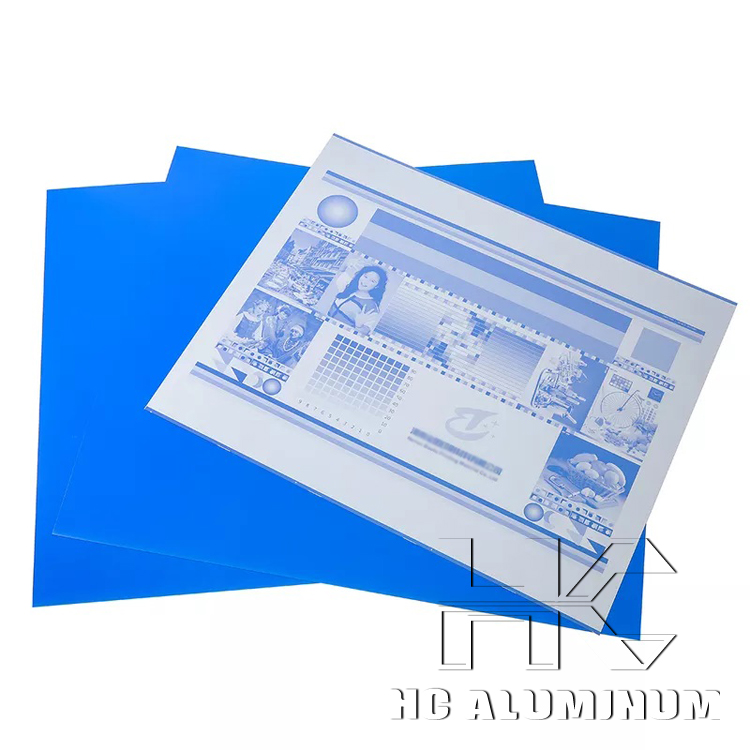

The mainstream offset printing plates are divided into PS plates and CTP plates. Both have their own characteristics. CTP plate making is gradually becoming the industry's first choice with its many advantages.

0.3mm thick CTP plates are especially suitable for medium to large-sized printing equipment and scenarios with high requirements for printing accuracy and durability.

CTCP (Computer to Conventional Plate) printing plate refers to the use of traditional PS plates with direct digital imaging, forming a new generation of UV-CTP plates.

Aluminum strip is a special aluminum-based material dedicated to the printing industry, mainly used to make printing plates for computer direct platemaking (CTP, Computer-To-Plate) technology. This kind of aluminum strip plays an important role in the mod

CTCP uses traditional PS plates and ultraviolet light, while CTP uses special plates and lasers.

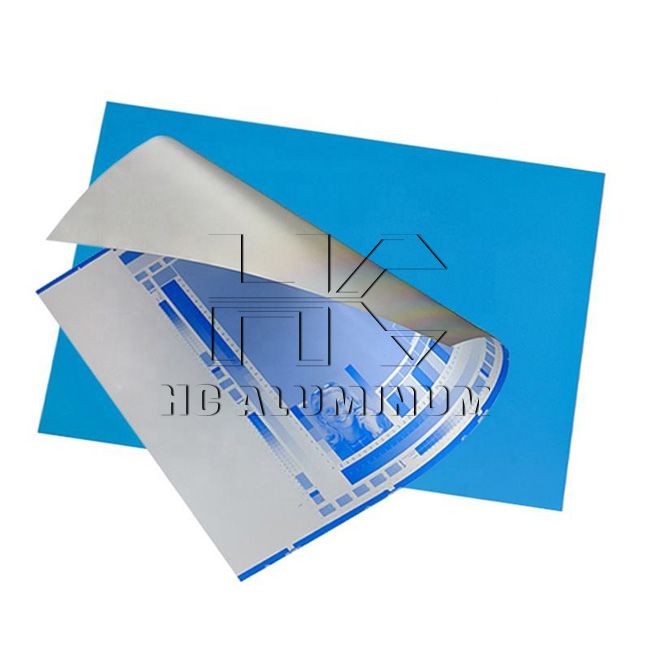

PS/CTP are both rolled into a certain thickness of thin plate through hot and cold rolling process. The surface of the plate is coated with a layer of photosensitive resin after a specific process treatment, and then dried to make a printing plate for var

CTP aluminum plate base is a material used in the printing industry. It is a printing platemaking technology that directly transfers the numbers, pictures or pages edited in the electronic prepress processing system or color desktop system to the printing

The core advantages of 830 nm thermal CTP plates lie in their operational stability and the convenience of working in a brightly lit environment.

Thermal CTP plates have higher exposure accuracy, more stable imaging characteristics and wider environmental adaptability, and are the preferred plate material in commercial printing, newspaper printing and other fields.

Process-free CTP plates effectively solve the problems of hazardous waste and emissions, and reduce electricity and water consumption, allowing you to achieve "green" printing.

Hongchang Aluminum currently produces four main types of CTP plates, including heat-sensitive, silver salt, photopolymerization and processing-free types.

Thermal CTP plates use an infrared thermal laser around 830nm to create images directly on aluminum-coated plates, eliminating the need for traditional film transfer processes.

Offset thermal CTP aluminum plate is a high-end printing plate made of aluminum plate as the substrate, coated with photosensitive material on the surface, ...