If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

Thermal Ctp Plate For Packaging Printing

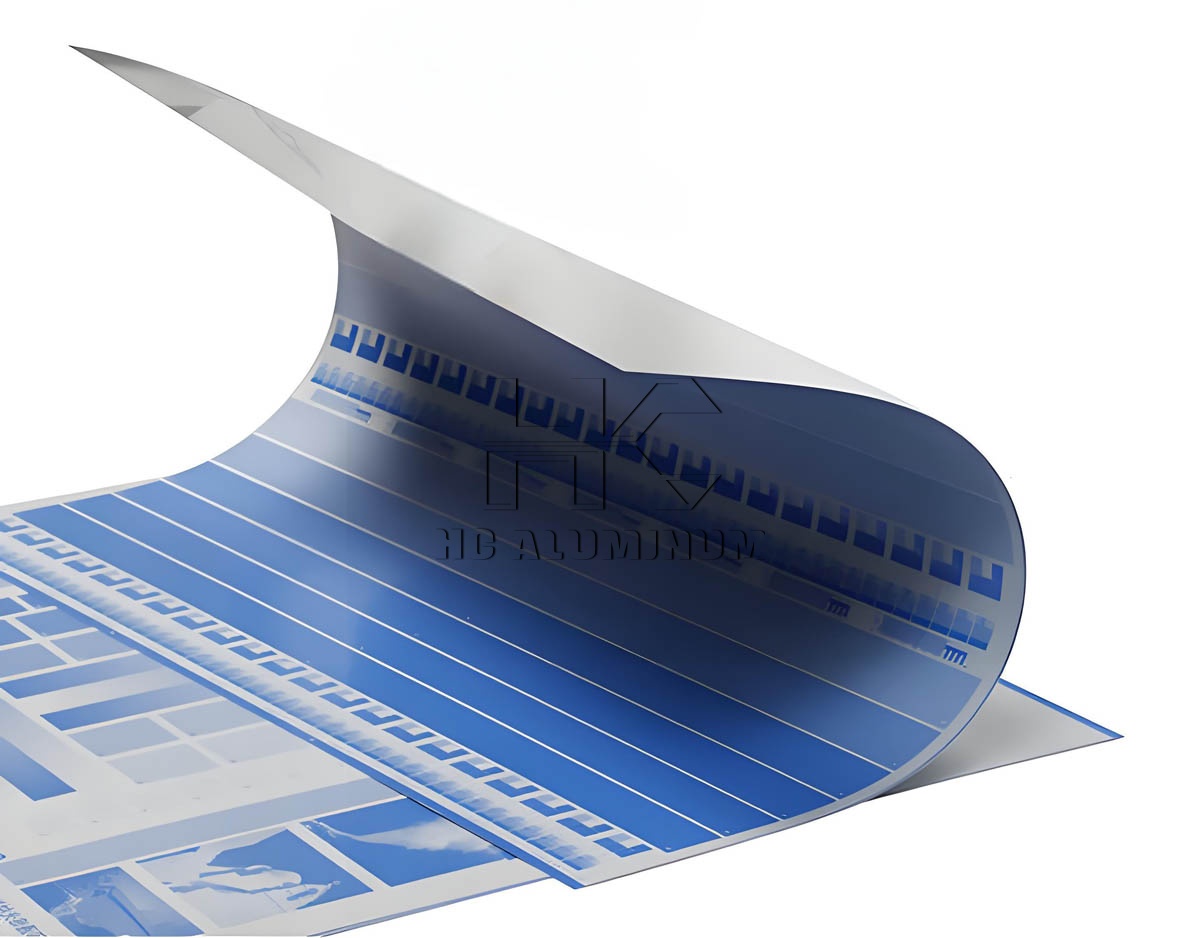

Packaging print jobs demand repeatable color, clean highlights, and reliable ink-water balance across long runs and frequent plate changes. A thermal CTP plate for packaging printing is positioned for offset packaging workflows where high-resolution thermal imaging (typically 830 nm) must translate into stable dot reproduction on press for folding cartons, labels, and flexible packaging components that require tight brand consistency.

Introduction to Thermal CTP Plates

Thermal CTP (Computer-to-Plate) plates are printing plate materials that utilize thermal lasers for direct imaging. They are widely used in the packaging printing industry, including applications such as cardboard box printing, pharmaceutical packaging, food packaging, and high-end commercial packaging printing. These plates typically use 830nm thermal lasers for exposure, offering stable imaging and insensitivity to ambient light, making them suitable for modern printing companies seeking standardized and automated plate-making processes.

Material foundation: aluminum that holds registration and chemistry

The performance of a lithographic plate begins with the aluminum substrate(1050/1060). Packaging converters commonly select premium aluminum with controlled gauge tolerance and low internal stress to minimize plate growth and improve registration on multi-color units. A well-engineered substrate supports:

Dimensional stability during plate making, baking, and pressroom temperature swings.

Uniform graining micro-topography to anchor the hydrophilic layer and manage fountain solution.

Consistent oxide and surface energy so that coating laydown and imaging response remain uniform across the sheet or coil.

In practice, substrate preparation is not only about strength; it is about building a repeatable surface architecture that keeps the non-image area strongly water-loving while allowing the imaged area to become ink receptive with sharp edges.

Coating system design: sensitivity, latitude, and durability in one stack

A modern thermal CTP plate for packaging typically uses a multilayer coating concept tuned for both imaging fidelity and press robustness. While formulations differ (positive-working vs negative-working), the coating system generally integrates:

A thermally sensitive imaging layer that converts laser energy into a solubility change or ablation-like switching behavior.

Functional binders and IR absorbers that define imaging speed, resolution, and tolerance to laser power drift.

Additives for scratch resistance and chemical resistance, important for packaging inks, alcohol-free dampening, and frequent wash cycles.

For packaging printing, the coating is often optimized for a wide processing latitude because production environments may vary in developer activity, replenishment rates, and water quality. The plate is expected to maintain predictable dot reproduction (including small text, barcodes, and fine screens) while resisting blinding, toning, or premature wear.

Manufacturing process: from coil to plate with controlled interfaces

Thermal plate consistency is built through process control that treats each interface (metal to oxide, oxide to coating) as critical:

Degreasing and cleaning remove rolling oils and particles that would otherwise create coating voids and imaging defects.

Electrochemical graining forms a controlled micro-roughness to support water retention and improve coating adhesion.

Anodizing creates a hard, porous aluminum oxide layer that improves wear resistance and corrosion performance; pore structure also influences coating anchoring and development behavior.

Sealing and surface treatment tune hydrophilicity and stabilize the oxide against press chemistry.

Precision coating and drying apply the thermal imaging layer with tight coat weight and uniformity; drying conditions are managed to avoid skinning, solvent retention, or sensitivity drift.

Finishing and inspection (cutting, punching, interleaving, and surface checks) focus on avoiding micro-scratches and ensuring repeatable imaging response.

The key manufacturing insight is that packaging applications amplify variability: high coverage solids, aggressive inks, and long runs punish weak oxide layers or marginal coating adhesion. Stable anodizing and coating uniformity directly translate into press run stability.

Core specifications for packaging-grade thermal CTP plates

| Item | Typical Range / Option | Notes for Packaging Printing |

|---|---|---|

| Imaging wavelength | 830 nm | Compatible with mainstream thermal platesetters |

| Plate thickness | 0.15-0.40 mm | Selected by cylinder packing and run length needs |

| Resolution capability | Up to 200 lpi (application dependent) | Supports fine screens, small text, barcodes |

| Coating type | Thermal positive or thermal negative | Chosen based on workflow and ink/water balance preferences |

| Processing | Developer processing or processless (variant dependent) | Processing latitude is critical for consistency |

| Run length | Medium to long (press conditions dependent) | Influenced by inks, fountain solution, abrasion, and optional baking |

| Surface base | Grained and anodized aluminum | Provides hydrophilicity and wear resistance |

| Safe-light handling | Yellow safe light (typical) | Follow plate chemistry requirements for storage and handling |

Practical performance in packaging workflows

In folding cartons and label work, plates face a combination of high ink density areas and fine detail elements (reversed text, micro-lines, and highlight dots). Thermal imaging's advantage is its inherent stability against ambient light and its ability to hold edge definition, which helps control dot gain and maintain smoother tonal transitions.

On press, packaging printers benefit when the plate's hydrophilic non-image area remains stable under modern dampening systems. A robust anodic layer and well-tuned surface treatment reduce background toning and make startup faster, especially in mixed-image layouts that combine solids and vignettes.

Where long runs or abrasive substrates are used, thermal plates are often paired with post-imaging treatments (such as baking, when applicable) to enhance mechanical and chemical resistance. The outcome sought in packaging printing is not just durability, but consistency: fewer mid-run adjustments, predictable trapping, and reliable reproduction across repeat jobs.

Integration considerations: matching plate behavior to ink and dampening chemistry

Packaging printing frequently involves specialized inks (high-pigment, metallic, or low-migration systems) and dampening practices that differ from commercial print. Plate selection should account for:

Developer compatibility and stability under site water conditions.

Resistance to plate cleaners and press washes used for packaging inks.

Tolerance to alcohol-reduced or alcohol-free dampening.

Ability to maintain clean non-image areas during high-coverage solid printing.

By aligning the aluminum surface, anodic structure, and coating chemistry with the pressroom's ink and fountain solution system, a thermal CTP plate for packaging printing can deliver stable imaging-to-press translation, dependable registration, and repeatable color across demanding packaging schedules.

Website: https://www.printarea-plate.com/a/thermal-ctp-plate-for-packaging-printing.html

Keyword: thermal CTP plate offset printing thermal CTP plates 830nm thermal CTP plates thermal CTP plate manufacturers printing plates

Previous: High Sensitivity Thermal Ctp Plate

Next: This is the last one!