If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

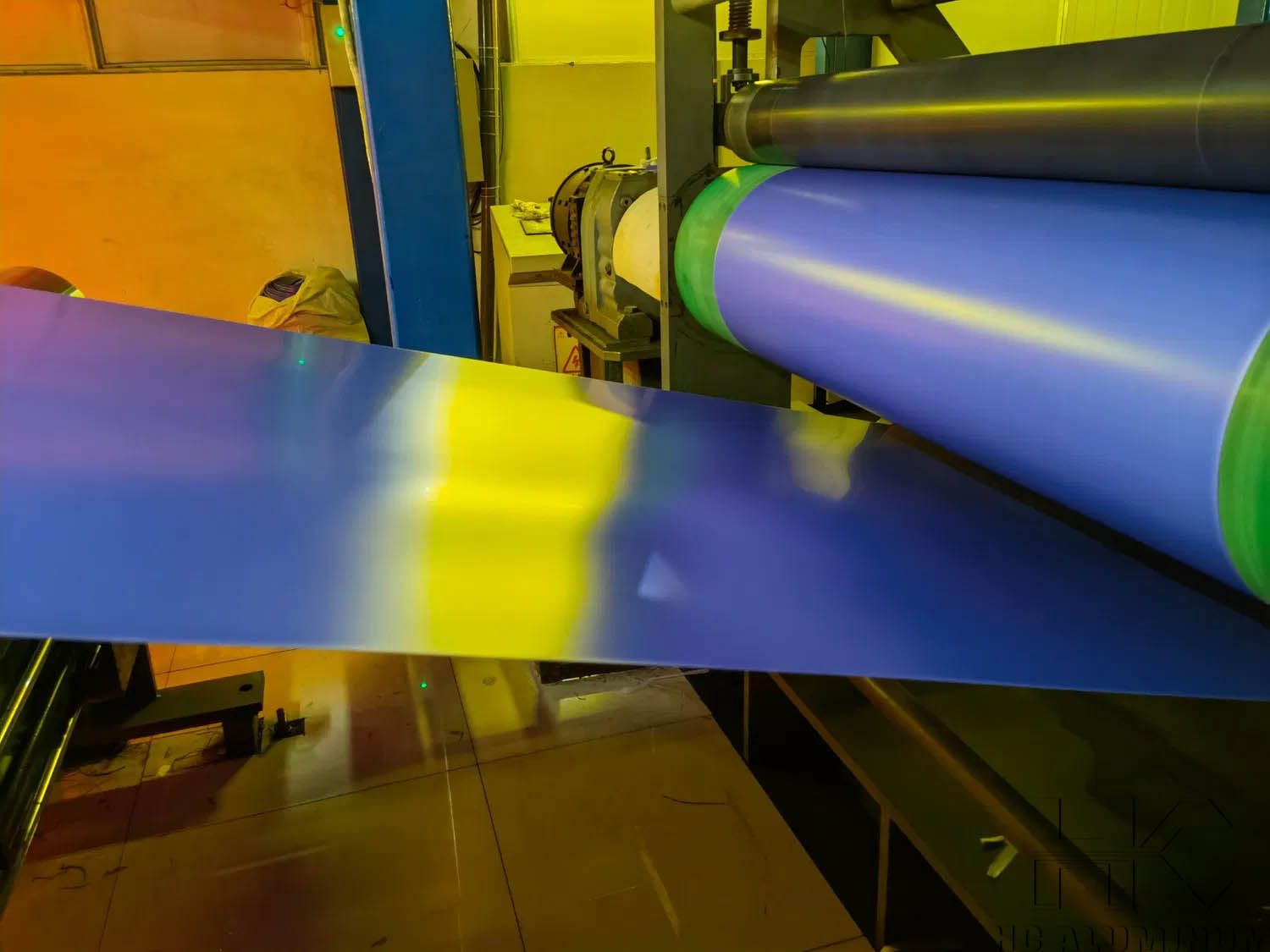

Offset thermal CTP aluminum plate

Offset thermal CTP aluminum plate is a high-end printing plate made of aluminum plate as the substrate, coated with photosensitive material on the surface, and produced by computer direct platemaking (CTP) technology.

In the platemaking process, the aluminum offset thermal CTP plate usually uses infrared laser exposure imaging, and can be printed on the machine after development processing. The plate base has a uniform and fine grain structure and a dense oxide film after a unique grain treatment process, which not only ensures the bonding strength of the thermal coating and the aluminum plate base, but also improves the high printing resistance and dot reproduction accuracy of the printing plate.

Offset thermal CTP aluminum plate has the following characteristics:

1. High-quality substrate: Usually 1 series pure aluminum plates, such as 1050 aluminum plates and 1060 aluminum plates, are used. These aluminum plates have the advantages of low density, high strength, easy forming, high stability, and good surface treatment, which are suitable as the substrate of CTP plates.

2. High plate making efficiency: The use of CTP technology can greatly improve plate making efficiency, shorten printing preparation time, and improve production efficiency.

3. High printing quality: Due to the excellent performance of the aluminum substrate and the precise coating of the photosensitive material, the thermal CTP plate shows high printing durability, sharp dot edges, and high printing quality during the printing process, which is suitable for high-end color printing.

4. Environmental protection and hygiene: Aluminum offset thermal CTP plates are environmentally friendly during the printing process, and are easy to clean and handle, meeting the environmental protection requirements of the modern printing industry.

5. Easy operation: It can work in a bright room without a dark room environment, which reduces the difficulty and cost of operation.

Scope of application:

Book, magazine, newspaper printing

Commercial printing (brochures, posters, packaging, etc.)

Fine dot printing (high-end albums, artwork reproduction)

Preparation process:

The preparation process of aluminum offset thermal CTP plate includes base preparation, imaging coating liquid preparation, coating and drying. Among them, base preparation is one of the key links, which involves the cleaning, roughening, oxidation and sealing of aluminum plates to ensure that the base surface has appropriate roughness and hydrophilicity. The preparation of imaging coating liquid directly affects the imaging performance and printing quality of the plate. The coating and drying steps determine the thickness and uniformity of the imaging layer.

Aluminum substrate requirements and selection:

1. Material composition: Select high-purity aluminum (generally 1050, 1060, 1070 aluminum alloy), and the content of iron (Fe) and silicon (Si) should be controlled within a reasonable range to ensure the ductility and corrosion resistance of the substrate.

2. Surface treatment: The surface treatment of aluminum requires no color difference, smooth and delicate, realistic color, strong powder adhesion and good weather resistance. These requirements can ensure that the aluminum maintains good appearance and performance during use.

3. Mechanical properties: The plate should be flat enough to ensure the accuracy of laser imaging and reduce image distortion caused by deformation during printing. The aluminum substrate cannot be too soft, otherwise it will be easily scratched; but it cannot be too hard, otherwise it will break easily under printing pressure.

4. Dimensional accuracy: Length and width errors are usually ≤ ±0.5mm; thickness errors are usually ≤ ±0.005mm;