If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

1050/1052/1060/1070 Aluminum PS substrate for printing

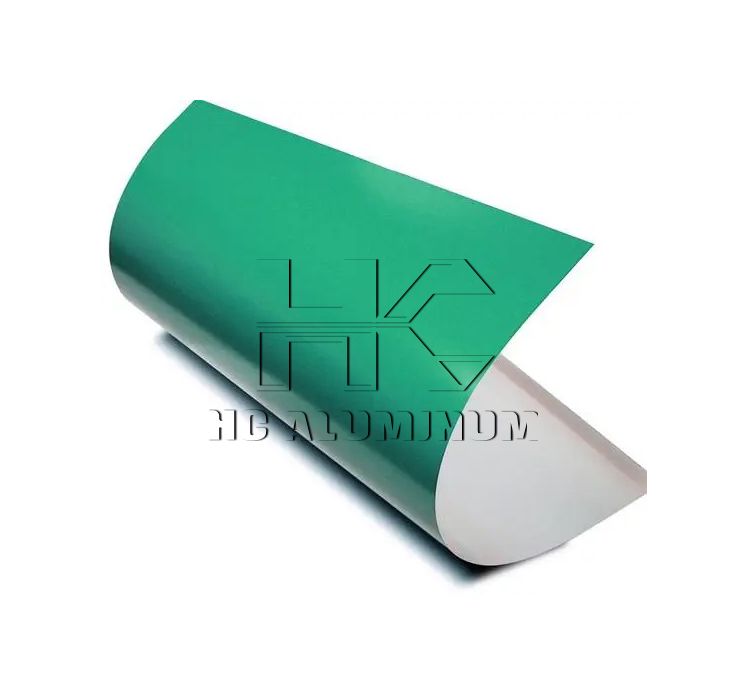

PS/CTP are both rolled into a certain thickness of thin plate through hot and cold rolling process. The surface of the plate is coated with a layer of photosensitive resin after a specific process treatment, and then dried to make a printing plate for various purposes.

PS plate is a lithographic plate pre-coated with a photosensitive layer, which consists of a photosensitive layer and an aluminum substrate. Aluminum plate requires sufficient strength, good dimensional viscosity and flatness, and has a surface state and chemical composition that is suitable for template decomposition. PS plates are commonly made of aluminum alloys such as 1050, 1060, and 1070. 1060-H18 state alloy is widely used in offset printing plates such as PS plates for printing, positive PS plates, and CTP plates.

PS aluminum sheet substrate for printing

| Alloy | 1050, 1060, 1070, 1052 |

| Temper | H18 |

| Thickness | 0.13-0.4mm |

| Width | 100-2100mm |

| Length | 100-16000mm |

| Application | positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates |

| Packing details | standard export wooden pallet or according to customer requirements |

| Delivery time | Within 25-30 days after receiving advance payment |

1 series aluminum sheet has the advantages of low density, high strength, moderate wear resistance, good formability, good hydrophilicity, high stability, good surface treatment, etc., making it an indisputable high-quality PS/CTP plate substrate.

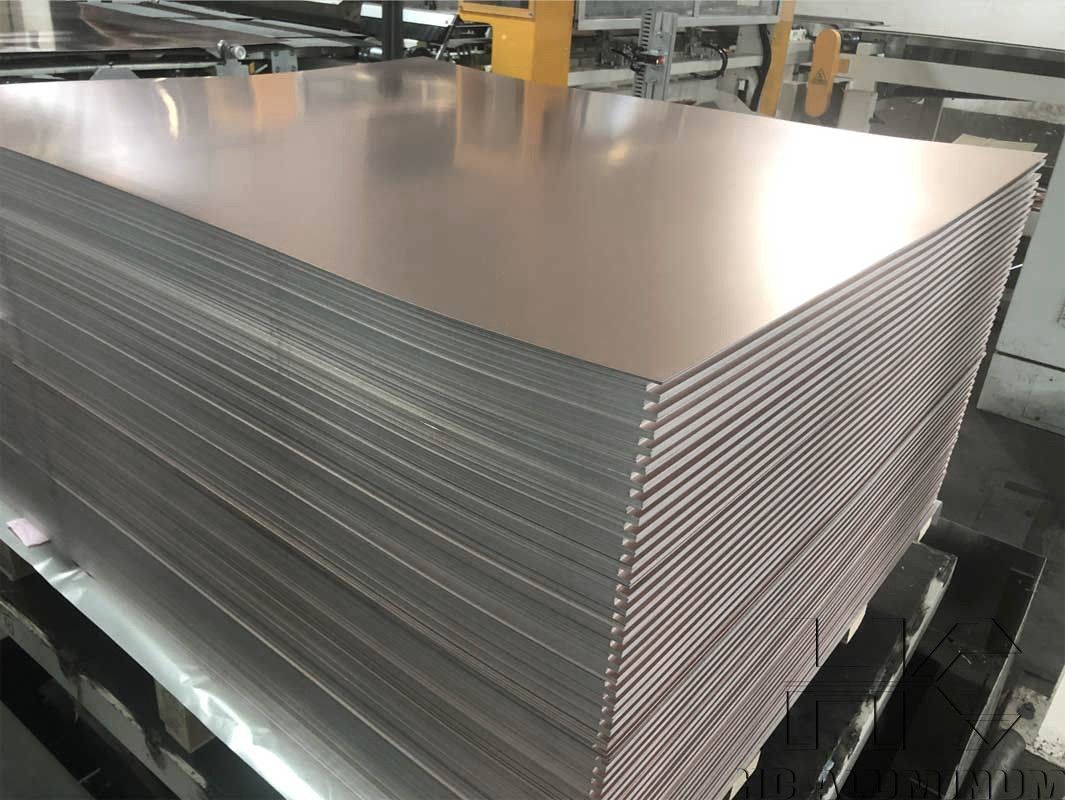

Hongchang Aluminum uses hot rolling technology to produce aluminum plate base for printing. The products produced by hot rolling method have good quality and high stability. The production process of hot rolling method: melting - casting - milling surface - heating - hot rolling - cold rolling - (annealing) - cold rolling - straightening - (longitudinal cutting) - finished product.

Since the surface quality and straightness of PS plate base aluminum strip are very high, in order to obtain high-quality PS plate base strip, a special straightening method must be adopted after cold rolling. In addition, the grit value of PS plate is generally 0.60~0.80μm. To obtain finer grit, the internal composition of the aluminum plate base is the key, which is related to the content and composition of trace special metals contained in the aluminum alloy.

Why choose Hongchang Aluminum?

1. Hongchang Aluminum's main production equipment for aluminum sheets and strips for printing includes melting furnaces, holding furnaces, online aluminum melt purification devices, casting and rolling mills/casting machines, sawing machines, milling machines, soaking furnaces, ingot heating furnaces, hot rolling mills, cold rolling mills, straightening mills/pure stretching mills, slitting mills, annealing furnaces, etc.

2. The surface of aluminum sheets and coils is absolutely clean and flat, without cracks, corrosion pits, scratches, oil marks and other defects.

3. We cater to global markets, including Africa, America, Asia, Europe, the European Union and the Middle East.