If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

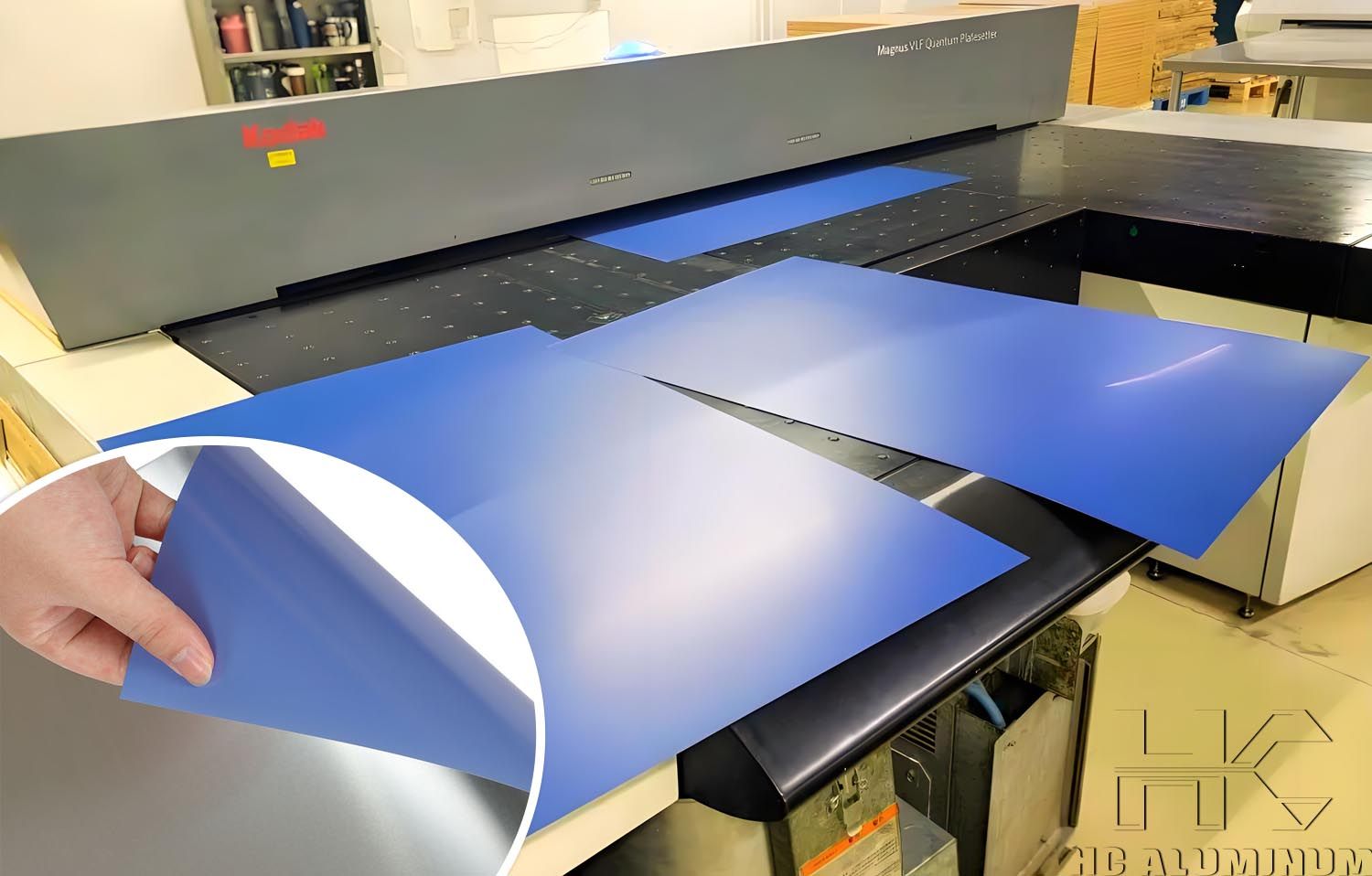

Thermal CTP Offset Printing Plate for Printing Machines

As commercial printing and packaging printing continue to move toward higher efficiency, greater stability, and environmental sustainability, the prepress plate-making process has become a critical factor affecting overall print quality and production cost. As a professional printing plate manufacturer, based on long-term production experience and customer feedback, we have observed that thermal CTP plates are increasingly becoming one of the core plate materials used with mainstream printing machines.

What Is a Thermal CTP Offset Printing Plate?

A thermal CTP (Computer to Plate) offset printing plate is imaged directly on an aluminum substrate using an infrared laser with a wavelength of approximately 830 nm. This technology eliminates the traditional film output process and enables the direct transfer of digital files to the printing plate.

Thermal CTP plates are typically composed of an aluminum substrate (commonly high-purity 1050 or 1060 aluminum), a thermal-sensitive photosensitive coating, and a protective or functional top layer. This structural design ensures stable performance in terms of imaging accuracy, mechanical strength, and printing durability.

Core Technical Features of Thermal CTP Printing Plates

1. High-Resolution Imaging and Accurate Dot Reproduction

Thermal CTP plates use infrared laser imaging directly on the aluminum surface, achieving resolutions of up to 200 lpi and supporting 1%-99% dot reproduction. This high-precision imaging technology ensures excellent detail and color fidelity, making it especially suitable for high-quality applications such as packaging printing, commercial printing, and book and magazine publishing.

2. Dual-Layer Structure and No Baking Requirement

Thermal CTP plates typically feature a dual-layer structure:

The top layer is a photosensitive material

The bottom layer is a heat-resistant layer

This design not only enhances plate durability but also eliminates the baking step required by traditional plates, resulting in a faster, more environmentally friendly production process.

3. Wide Compatibility Across Applications

Thermal CTP plates are compatible with mainstream thermal plate setters such as Dainippon Screen, CRON, and others. They also support multiple printing press types, including offset, gravure, and web printing machines. Whether for large-format printing or small-size jobs, stable and reliable performance can be maintained.

4. Long Service Life and High Durability

In the non-baked condition, thermal CTP plates can achieve a run length of up to 350,000 impressions. After baking, the run length can be extended to up to 2 million impressions. This high durability significantly reduces plate change frequency and overall production costs.

Thermal CTP Plate Technical Parameters

| Spectral Sensitivity | 800-830 nm |

| Exposure Energy | 110-130 mJ/cm² |

| Resolution | 200 lpi (1%-99%) |

| Run Length (Non-baked) | 80,000-120,000 impressions |

| Run Length (Baked) | Up to over 1,000,000 impressions |

| Print Compatibility | Compatible with standard fountain solutions and inks |

| Developer Temperature | 22-28°C |

| Maximum Plate Size | 1650 × 1350 mm |

| Service Life | Non-baked: 350,000 impressions; Baked: up to 2,000,000 impressions |

Application Value of Thermal CTP Plates on Offset Printing Presses

1. Improved Print Quality and Consistency

The high resolution and accurate dot reproduction of thermal CTP plates ensure sharp images and consistent color output. This is particularly important in packaging printing, where visual quality directly influences purchasing decisions.

2. Faster Production Cycles

By eliminating baking and complex chemical processing steps, thermal CTP plates can reduce the plate-making cycle by 30%-50%, significantly improving production efficiency and market responsiveness.

3. Reduced Environmental and Operating Costs

Thermal CTP plates reduce chemical consumption and waste generation, aligning with the sustainability goals of the modern printing industry. Their long service life further minimizes plate replacement frequency, resulting in lower overall costs.

4. Adaptability to Diverse Printing Jobs

Whether for high-quality packaging printing or large-volume commercial printing, thermal CTP plates deliver stable performance and meet diverse and customized customer requirements.

Application Scenarios for 830nm Thermal CTP Plates

Commercial brochures, flyers, magazines, and periodicals

High-end packaging color printing (food, daily chemical, and pharmaceutical packaging)

Label printing and spot-color printing

Medium- and long-run jobs and repeat order production