If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

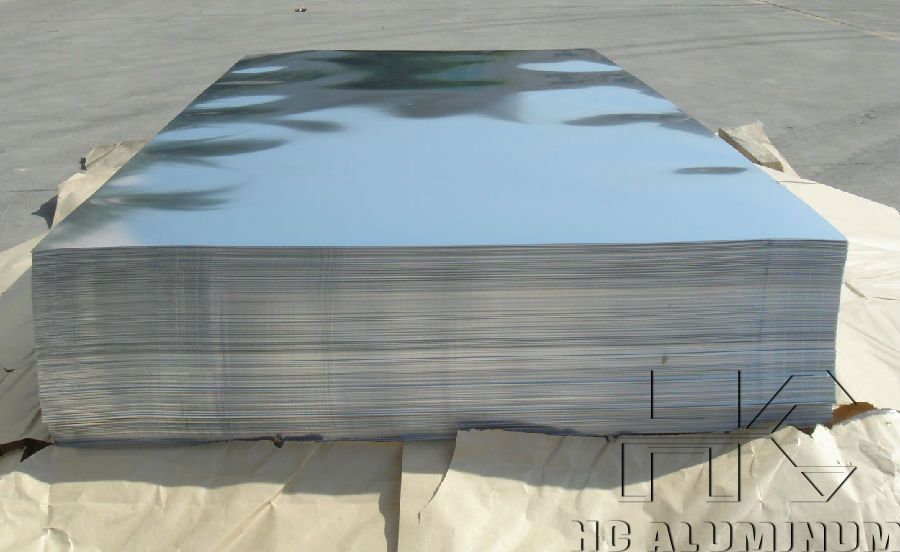

Aluminum for printing 1050A 1060

PS/CTP plates can be collectively referred to as printing plates or offset plates. They are plates that are coated with a photosensitive layer on an aluminum substrate (provided by MC Aluminum) and can be printed on the machine after plate making.

The substrates of modern printing plates are all aluminum plates, and the commonly used alloy numbers are 1050, 1060, 1070, 1052, etc., and their aluminum contents are ≥99.50%, ≥99.60%, ≥99.70%, and ≥99.52% respectively. Aluminum substrate has the advantages of low density, high strength, moderate wear resistance, easy processing, good forming, good hydrophilicity, high stability, good surface treatment, strong recyclability, easy regeneration, abundant resources, and reasonable price, making it an indisputable high-quality PS/CTP substrate.

Specifications of aluminum plates for printing:

| Alloy | 1050, 1060, 1070, 1052 |

| Temper | H18 |

| Thickness | 0.13-0.40mm |

| Width | 650-2250mm |

| Length | 100-16000mm |

| Coating color | blue, green |

| Application | positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates |

PS/CTP plate base performance parameters:

| Alloy | Tensile strength (normal temperature) | Tensile strength (baked plate) | Elongation after fracture |

| 1050A | 185~215MPA | 125~140MPA | >1% |

| 1060 | 200~230MPA | 125~140MPA | >1% |

PS plate aluminum plate base is divided into three categories:

1. Ordinary printing PS plate base, for ordinary paper printing such as newspapers and books;

2. Color printing PS plate base, for pictures, color printing text and special paper printing;

3. CTP printing PS plate base, for computer direct plate making.

Printing requirements for aluminum plate base:

1. High surface flatness. When printing, the surface of the aluminum plate is not allowed to have defects such as unevenness or impurities.

2. Moderate hardness. The aluminum plate should not be too hard to avoid scratches or wear during printing, nor too soft to avoid paper slip or deformation.

3. Moderate thickness. The thickness of the aluminum plate should be determined according to the requirements of the printed matter. Generally speaking, the thickness of the flat printing plate is between 0.15-0.3mm, and the thickness of the rotary plate is between 0.3-0.5mm.

4. Good corrosion resistance. Aluminum plates should be treated with chemicals during the production process, and the aluminum plate itself is required to have a certain corrosion resistance.

Hongchang Aluminum has formed a systematic ingot hot rolling and continuous casting strip production system, using continuous casting strip production PS aluminum plate base, CTP aluminum plate base production ingot hot rolling strip, with good quality, high yield and stable performance. The company provides 1 series aluminum plates for the production of PS/CTP plates, with a complete range of product models, exported overseas, short delivery time and preferential prices.