If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

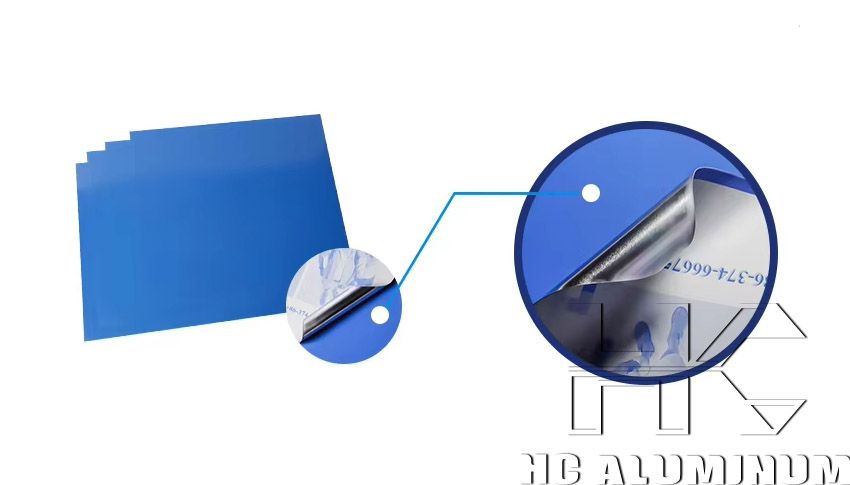

CTP printing aluminum substrate

The CTP plate in the printing industry refers to the printing platemaking technology that directly transfers the numbers, pictures or pages edited in the electronic prepress processing system or color desktop system to the printing press without subsequent processing.

In CTP printing aluminum substrates, the commonly used aluminum plate base alloys are 1050, 1060, etc., and the aluminum content of these alloys is ≥99.50% and ≥99.60% respectively. These aluminum materials have the advantages of low density, high strength, easy forming, high stability, and good surface treatment, so they are ideal choices for PS/CTP substrates.

Where is the CTP substrate used?

CTP substrates are widely used in offset printing plates such as positive PS plates, thermal CTP plates, photosensitive CTP plates, and UV-CTP plates.

Specifications of aluminum for CTP substrate:

| Alloy series | 1 series |

| Typical alloys | 1050A, 1060,1070 |

| Temper | H18 |

| Thickness | 0.13-0.40mm |

| Width | 650-1420mm |

| Length | C |

| Color | blue |

| Application | newspaper printing and commercial printing |

Features of CTP substrate:

1.High printing quality: The surface flatness of CTP printing aluminum substrate is high, which can ensure the stability and consistency of printing quality, thus meeting the needs of high-quality printing.

2.Strong printing resistance: CTP printing aluminum substrate has high hardness and strength, can withstand high-intensity printing force, and ensure that the printing quality remains stable during long-term and high-intensity printing.

3.Environmentally friendly: CTP printing aluminum substrate is made of environmentally friendly materials, does not contain harmful substances, does not pollute the environment, and meets the environmental protection requirements of the modern printing industry.

4.Cleanliness: The surface of CTP printed aluminum substrate is smooth and not easy to be contaminated with dust and dirt, which can ensure the hygiene and cleanliness of printed products, which is especially important for packaging printing in industries such as food and medicine.

5.Reasonable cost: The price of CTP printed aluminum substrate is relatively low and the cost is reasonable, which enables printing companies to effectively control costs and improve economic benefits while ensuring printing quality.

In addition, CTP printed aluminum substrate also has the advantages of low density, high strength, easy forming, high stability, and good surface treatment. These advantages make CTP printed aluminum substrate have a wide range of application prospects in the field of printing platemaking.

CTP plate material has very high requirements for the quality of the plate base:

1. CTP plate base has very high requirements for the surface quality of the aluminum substrate. The surface needs to be clean and flat, without cracks, corrosion pits/spots, vents, scratches, folds, marks, peeling, pine branch patterns, oil marks and other defects to ensure the quality of the printing plate.

2. CTP plates have high requirements for the flatness of the plate base, and no unevenness is allowed, because most CTP equipment uses scanning imaging, unlike PS plates, which use vacuuming to make the plate surface and the film fit tightly. If the plate flatness is poor, it will affect the quality of laser imaging.

What is the difference between CTP plates and PS plates?

CTP plates are computer-to-plate and are high-end products of PS plates.

| Features | CTP plate | PS plate |

| Platemaking method | The computer directly transfers the image to the plate | The image is transferred through film exposure and chemical processing |

| Platemaking accuracy | High accuracy, suitable for detailed patterns and high-resolution printing | Lower accuracy, suitable for general printing tasks |

| Production efficiency | High, high degree of automation, reduced manual operation | Low, cumbersome process and manual operation required |

| Environmental protection | High, no film and chemicals are used | Low, photosensitive film and chemicals are required |

| Image quality | High quality, strong stability | Low, may have color difference and instability problems |

| Scope of application | High-end printing, commercial printing, mass production | Low-precision printing, small-batch production |

| Cost | High initial investment, but low long-term cost | Low initial investment, but high long-term cost |

| Maintenance and operation | Easy to operate and maintain | Complex operation and high maintenance requirements |