If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

CTP plate requirements for the plate base

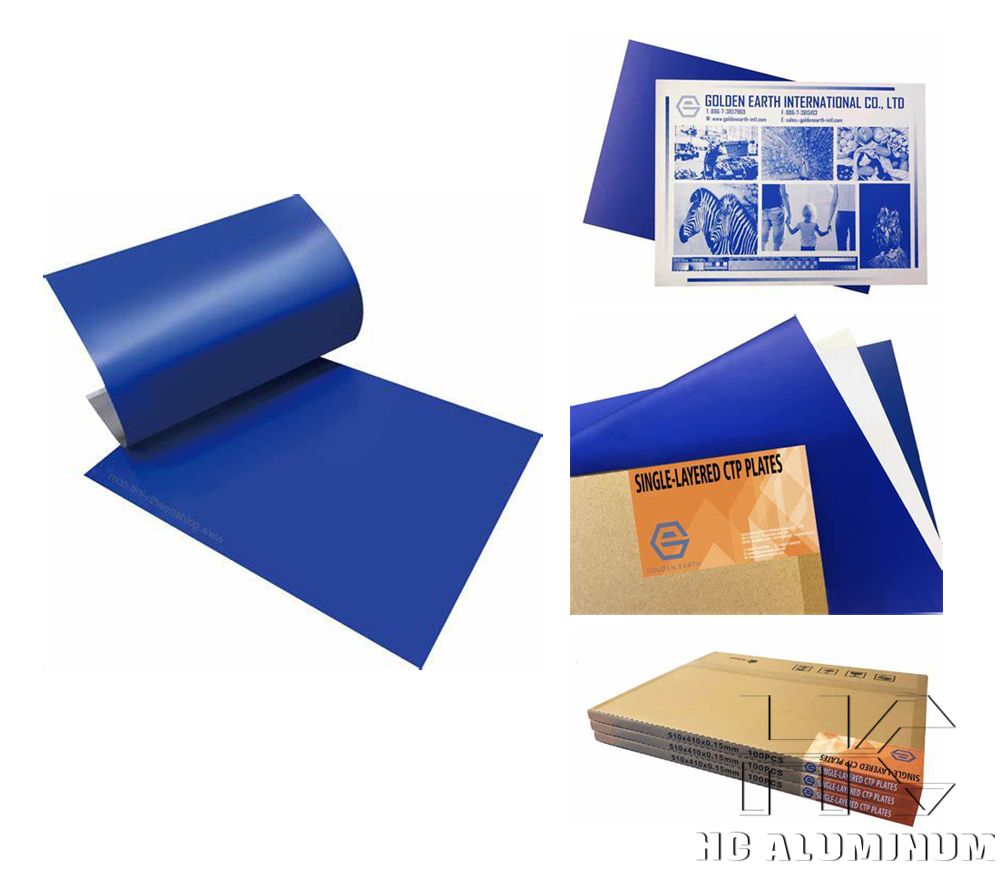

CTP plate is a high-end direct platemaking technology, widely used in different types of offset printing plates, such as positive PS plate, thermal CTP plate, photosensitive CTP plate and UV-CTP plate. CTP plate has the advantages of high printing quality, strong printability, environmental friendliness, cleanliness and sanitation, and reasonable cost. With the development of CTP technology and the decline in prices, more and more printing practitioners like to use CTP plates, and the usage is also increasing rapidly, with a trend of surpassing traditional PS plates.

CTP plate is a high-end product, widely used in offset printing plates such as positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate, etc. It has the advantages of high printing quality, strong printability, environmental friendliness, cleanliness and sanitation, and reasonable cost. With the maturity of technology and the decline in prices, CTP technology is favored by printing practitioners and its usage is increasing rapidly. CTP plates are surpassing traditional PS plates.

At present, the commonly used alloys for CTP bases are 1110, 1050, 1052, 1060, 1070, etc. CTP base 1 series alloys have the advantages of low density, high strength, good forming, good hydrophilicity, high stability, and good surface treatment.

The overall requirements for aluminum substrates in printing are very high, especially since CTP plates are mostly used for high-end color printing. To ensure the quality of the printing plate, the requirements for CTP base are as follows:

1. Surface quality requirements:

Requirements for the surface performance of the base:

The basic requirements for the appearance of aluminum substrates are clean and flat, without cracks, corrosion pits, points, vents, scratches, folds, marks, peeling, pine branch patterns, oil marks and other defects; non-metallic indentation and adhesion, horizontal skin, horizontal lines and other defects are not allowed on the surface; slight color difference, bright strips and other problems are not allowed; there should be no bulges, ruffles and other phenomena.

The CTP plate must be completely flat, otherwise it will affect the quality of laser imaging. CTP plate production has the following three specific requirements for the flatness of the plate base:

(1) The gap between the unfolded surface of the aluminum coil and the plane should not be greater than 1mm, and the number of waves per meter of the unfolded surface should not exceed 3;

(2) The side bend should not be greater than 1mm per meter;

(3) The aluminum coil should be tight and the end surface should be neat, without cracks or burrs.

2. Physical performance requirements:

CTP plate making machine has a high plate making speed, automatic plate loading and positioning punching, and strict requirements on the geometric dimensions of the plate base, including thickness, width, uniformity, etc.

(1) Thickness and tolerance of aluminum plate base

The thickness of the aluminum plate base used for CTP plates is generally 0.280mm, which is slightly thicker than PS plates (thickness is 0.270mm±0.005mm). Some foreign companies use 0.275mm thick aluminum plate bases, and the thickness tolerance is ±0.005mm. The thicker the aluminum plate base, the better the plate stiffness and the less likely it will bend.

(2) Aluminum coil width tolerance

my country's plate production generally does not install online trimming devices, so the width tolerance of aluminum coils is required to be ≤±0.5mm, preferably no tolerance.

There are also clear requirements for the cutting quality of aluminum coils, that is, there should be no burrs, ruffles, etc. on both sides of the aluminum coil after longitudinal cutting. Of course, the electrolytic edges on both sides should be trimmed before coating.

(3) Longitudinal and transverse uniformity of the plate base

The longitudinal and transverse thickness tolerances of the aluminum plate base should be ≤±0.005mm. The thickness of the plate is mostly set to 0.280mm or 0.275mm for various types of platemaking machines; thickness deviations will affect platemaking, and the parameters set by CTP platemaking machines are generally not allowed to be adjusted at will.

3. Adaptability to electrolytic performance requirements

CTP plates require good adaptability during the electrolytic treatment process to ensure the uniform distribution of the electrolyte and the smooth progress of the electrolytic reaction. This requires the plate base material to have stable chemical and physical properties under electrolytic conditions.

4. Other requirements

Surface roughness: The surface roughness of the CTP plate base also has certain requirements to ensure the clarity and accuracy of laser imaging.

Corrosion resistance: The plate base should have a certain degree of corrosion resistance to resist corrosive substances that may be encountered during plate making and use.