If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

Hot-rolled aluminum sheet for CTP plate

Hot-rolled aluminum sheet is an aluminum sheet that has been processed by hot rolling process, with high strength, good ductility and processing performance. In CTP platemaking technology, hot-rolled aluminum sheet is used as the substrate of the printing plate, carrying the transfer and printing process of graphic information.

Common hot-rolled aluminum sheet alloys for CTP plates include 1100 alloy aluminum sheet.

Hot-rolled 1100 CTP aluminum sheet belongs to the pure aluminum sheet series, with relatively low strength, but excellent ductility, formability, weldability and corrosion resistance; after anodizing treatment, the corrosion resistance can be further improved and a beautiful surface can be obtained; but it cannot be strengthened by heat treatment.

Specifications:

| Alloy | 1100, 1050, 1060, 1070, etc |

| Temperature | H18 |

| Thickness | 0.13-0.4mm |

| Width | 100-1600mm |

| Length | C |

| Application | positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates |

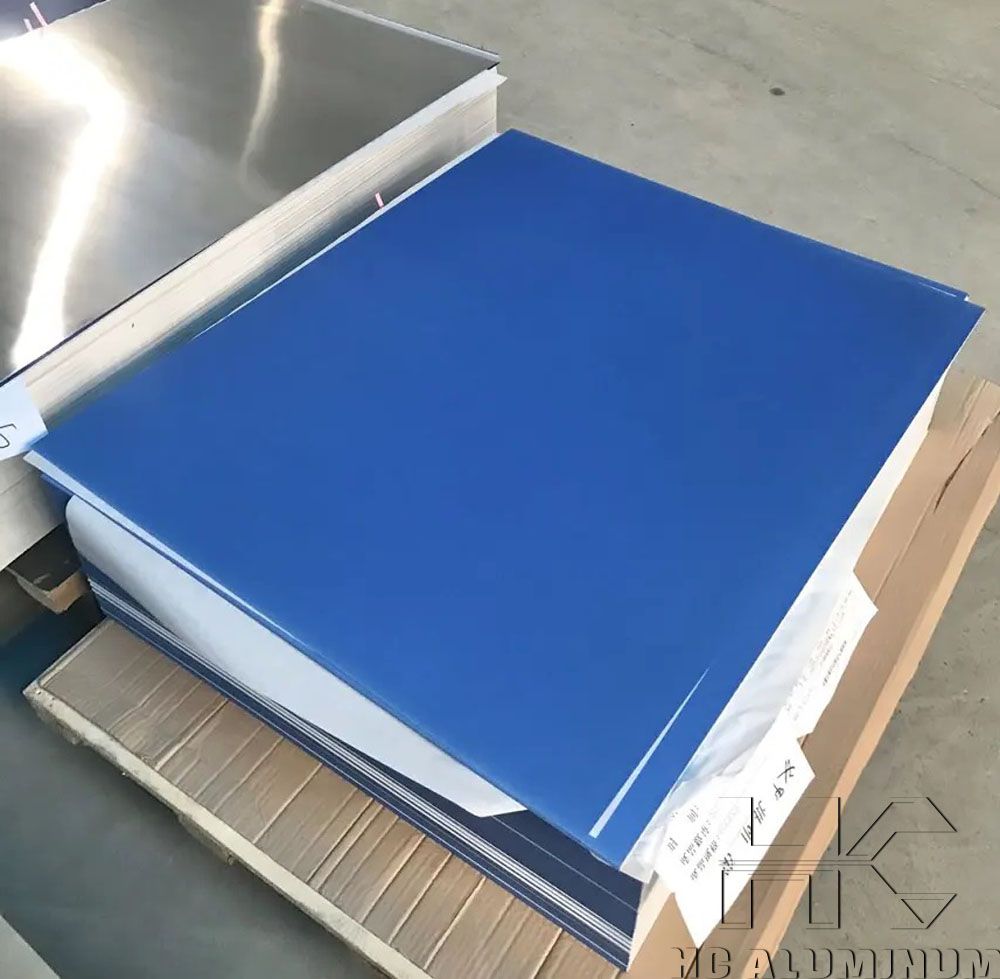

| Color | blue, green |

| MOQ | 1-3 tons |

| Sample | free |

| Packaging | standard export wooden box |

| Delivery time | 25-35 days after payment |

Advantages of hot-rolled aluminum plate for CTP plate:

1. High flatness: The hot-rolled aluminum plate has excellent flatness after stretching treatment, which ensures good contact of the CTP plate on the printing press and improves the printing quality.

2. Good mechanical properties: The grain is refined and the stress is uniform during the hot rolling process. The aluminum plate has high strength and toughness, which is suitable for high-speed printing.

3. High surface finish: The surface treatment after hot rolling makes the aluminum plate smooth, which is conducive to high-resolution image presentation.

4. Strong corrosion resistance: Hot-rolled aluminum plates usually have high corrosion resistance, which prolongs the service life.

5. Wide adaptability: It can adapt to different types of CTP platemaking equipment and processes to meet diversified printing needs.

CTP plate application:

Hot-rolled aluminum plates for CTP plates are widely used in the printing industry, especially in fields that require high-precision and high-quality printing, such as books, newspapers, advertisements, packaging, etc. In the CTP platemaking process, hot-rolled aluminum plates, as the substrate of the printing plate, carry the transfer and printing process of graphic information, which is of great significance for improving printing quality and efficiency.

Quality requirements for CTP hot-rolled aluminum plates:

1. Surface quality requirements: The surface is flat, clean, oil-free, defect-free, with neat edges, no burrs, ruffles, etc.

2. Geometric size requirements: The dimensional accuracy of width and length must be strictly controlled, and the error is usually required to be within ±0.5 mm to ensure the installation and adaptability of the printing plate.

3. Chemical composition requirements: The aluminum plate should meet specific alloy standards (such as 1050, 1060) to ensure processing performance and stability.

4. Surface roughness requirements: The average value Ra is between 0.17~0.21μm, the lateral Ra allowable deviation is ±0.02μm, and Rz≤2.5μm to improve printing quality.

Website: https://www.printarea-plate.com/a/hot-rolled-aluminum-sheet-for-ctp-plate.html

Keyword: hot-rolled aluminum sheet CTP plate 1100 aluminum sheet pure aluminum sheet

Previous: Aluminum plate base for printing plates