If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

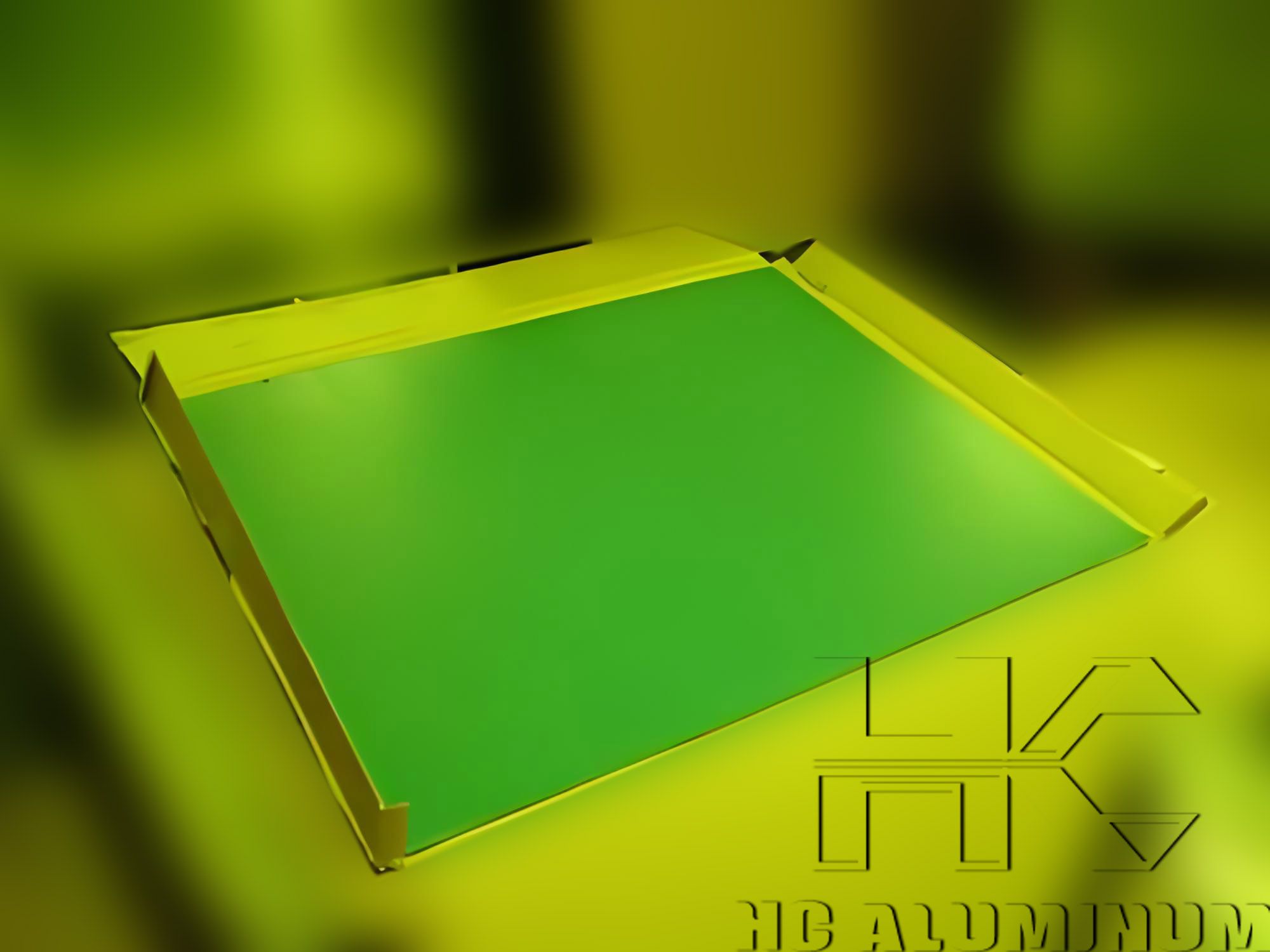

Aluminum Printing PS Plate

Aluminum Printing PS Plate is a photosensitive material commonly used in the printing industry, mainly used for lithography (also known as offset printing). The full name of PS plate is "pre-coated photosensitive plate". Its main features are high precision and durability through the combination of photosensitive materials and aluminum substrates, and it is suitable for large-scale printing tasks. It is used in various printing fields, such as books, magazines, newspapers, packaging, advertising, etc. Its high-quality printing effect and stable performance make it one of the important materials in the printing industry.

Composition of Aluminum Printing PS Plate

Aluminum Substrate:

Usually high-purity aluminum plate is used as the substrate, and the common alloy grades are 1050 or 1060 series (purity of more than 99.5%). It has excellent strength, corrosion resistance and thermal conductivity, which ensures the stability and service life of the PS plate.

Oxide layer:

Anodizing is performed on the surface of the aluminum plate to form a layer of aluminum oxide film, which improves the surface hardness and adhesion, while increasing wear resistance and corrosion resistance.

Photosensitive layer:

The photosensitive material coated on the oxide layer is sensitive to ultraviolet light or other specific wavelengths of light, and forms a printed image through exposure and development.

Protective layer

There may also be a protective layer (transparent polymer material) on the surface of the photosensitive layer to improve storage stability and prevent scratches and contamination.

Performance of printed PS aluminum plate

1. High resolution and clarity: fine sand mesh, smooth dots, good color reproduction, and clear image.

2. Wear resistance and acid resistance: diazo photosensitive resin is wear-resistant and acid-resistant, and the hardness is increased after baking, and the printing rate can reach 200,000 to 300,000 sheets.

3. Hydrophilic and lipophilic properties: Aluminum oxide film is hydrophilic, wear-resistant and chemically stable; diazo photosensitive resin is lipophilic, ink is easy to spread, and water is difficult to spread.

4. Convenient use and stable quality: Professional and centralized production, photosensitive glue and drying quality assurance, convenient use, stable quality.

Applicable scenarios

Aluminum printing PS plates are widely used in printing fields such as books, newspapers, packaging, brochures, etc., especially in high-quality and large-volume printing.

MC Aluminum is a large aluminum plate manufacturer for PS plate base/CTP plate base production. The aluminum plates such as 1050A aluminum plate, 1060 aluminum plate, 1050 aluminum plate, 1070 aluminum plate, etc. used in the production of printed PS/CTP plates are flat and clean. It has long-term cooperation with many large foreign companies and is highly trusted by customers.

Website: https://www.printarea-plate.com/a/aluminum-printing-ps-plate.html

Keyword: Aluminum Substrate PS Plate Aluminum Plate

Previous: 1050A PS aluminum-based sheet