If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

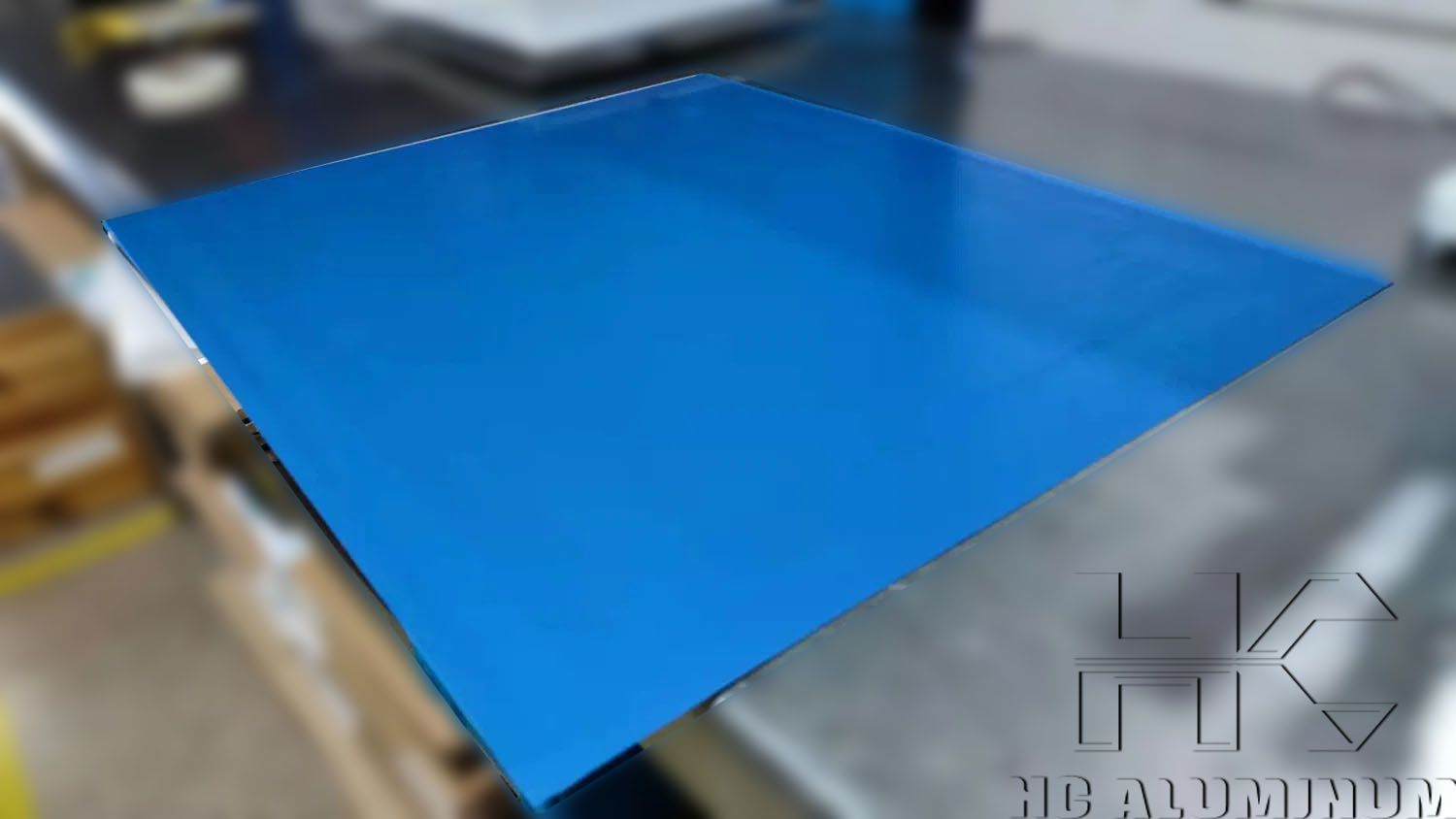

Blue thermal coating CTP / PS offset printing aluminum plate

Blue thermal coating CTP/PS offset printing plate usually uses high-quality aluminum plate as the plate base. Aluminum plate has good ductility, corrosion resistance and light weight, which is suitable for making printing plates. A special blue thermal coating is applied on the surface of the aluminum plate. This coating is sensitive to infrared lasers and can undergo chemical or physical changes under laser irradiation to form graphic information.

The alloy types of aluminum plates for printing bases usually include 1050, 1060, 1070, 1100, etc. These alloys have the advantages of low density, high strength, good formability, good hydrophilicity, high stability and good surface treatment.

Specifications of printed aluminum substrates:

| Product series | 1 series aluminum sheets |

| Alloys | 1050, 1060, 1070, 1100, etc. |

| Temper | H18 |

| Thickness | 0.13-0.40mm |

| Width | 680-1600mm |

| Length | customized according to customer needs |

| Surface color | blue |

Features of blue thermal coating CTP/PS aluminum plates:

1. High precision and consistency

Digital platemaking technology ensures that the patterns and texts printed each time are high in precision and consistency, suitable for complex designs and high-end printing needs.

2. Dynamic response of thermal coatings

The coating can change color or display hidden information when the temperature changes, suitable for smart packaging, cold chain monitoring and anti-counterfeiting design.

3. Superior durability

The aluminum plate substrate is anti-oxidation and anti-corrosion, and the coating is not easy to fall off or fade, which is suitable for various storage and transportation environments.

4. Environmental protection characteristics

The CTP platemaking process reduces the emission of chemical waste, and both the aluminum and the coating can be recycled, which is in line with the concept of sustainable development.

Blue thermal coating CTP/PS aluminum plate application scenarios:

Blue thermal coating CTP/PS printing offset aluminum plate is widely used in newspapers, books, magazines, packaging and other printing fields. Its high-quality printing effect and stable performance make it one of the important plates in the printing industry.

1. Book printing: suitable for the printing of various books, including textbooks, novels, picture albums, etc., which can ensure clear text and realistic images, and improve the printing quality and ornamental value of books.

2. Packaging printing: widely used in the packaging printing of various products such as food, beverages, cosmetics, electronic products, etc., which can print exquisite packaging patterns and texts, and enhance the packaging grade and market competitiveness of products.

3. Commercial printing: such as the printing of commercial promotional materials such as posters, leaflets, business cards, invitations, etc., which can meet the requirements of different customers for printing quality and effect, and help enterprises better promote products and services.

Quality requirements for aluminum plate substrates for printing:

1. The thickness of aluminum plate should be uniform, the thickness tolerance should be controlled within ±0.02mm, and the flatness error should be less than 0.5%.

2. There are no obvious scratches, bubbles or particles on the surface of the aluminum plate, no pollutants such as oil stains, and the gloss is uniform.

3. The surface of the aluminum plate must be flat without obvious bumps, and the warping should be less than 0.5%.

4. The aluminum plate should have good oxidation resistance and corrosion resistance to adapt to different storage environments and long-term use requirements.

5. The aluminum plate substrate needs to have appropriate hardness (usually HB 20-30) and tensile strength (≥150MPa) to meet the needs of mechanical pressure during printing.

Website: https://www.printarea-plate.com/a/blue-thermal-coating-ctp-ps-offset-printing-aluminum-plate.html

Keyword: CTP/PS plate aluminum plate for printing plate base aluminum plate substrate printing aluminum substrate

Previous: Aluminum plate for printing house