If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

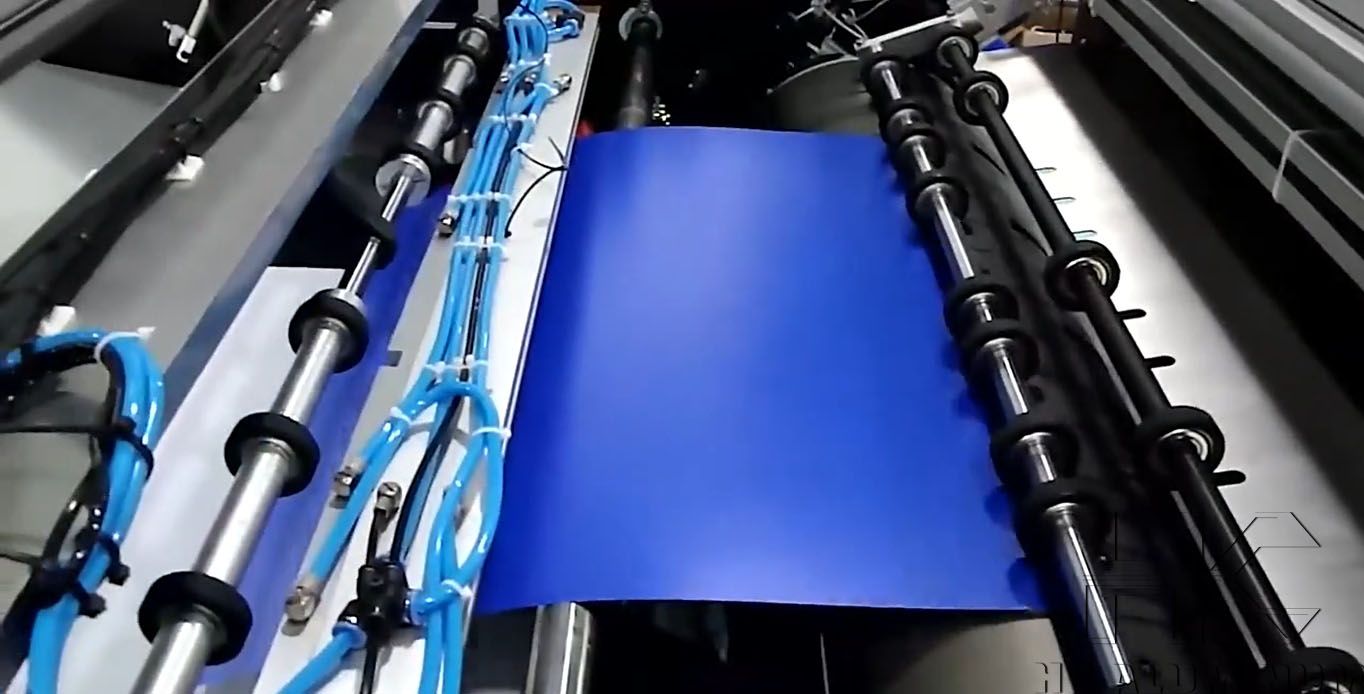

Five characteristics of printed aluminum plate

Printed aluminum plate is a metal substrate used in the printing industry, usually used as the base material of PS plate (pre-coated photosensitive plate) or CTCP plate (computer direct plate). It has been specially processed to meet the requirements of imaging accuracy, durability and chemical stability in the printing process, and is an indispensable part of modern offset printing technology.

Printed aluminum plate usually uses aluminum alloy as the substrate, commonly used 1050 aluminum alloy, 1060 aluminum alloy, 1070 aluminum alloy, etc., with aluminum content of 99.5%, 99.6%, 99.7% respectively, high purity, better surface finish, suitable for high-precision imaging printing needs.

Advantages of printed aluminum substrate for CTCP/PS plate:

1. Excellent flatness and dimensional stability

Aluminum plate has excellent flatness, ensuring the accurate presentation of images and text during printing. At the same time, it has strong deformation resistance and is not affected by temperature and humidity changes, which makes aluminum plate have good stability in high-speed printing equipment.

2. High durability and corrosion resistance

Aluminum itself has a high antioxidant capacity. After special treatment, it can effectively prevent the corrosion of chemicals on the plate during the printing process. This durability not only increases the life of the aluminum plate, but also reduces the frequency of plate replacement during production, improving production efficiency.

3. Excellent thermal conductivity and heat dissipation

The aluminum plate has good thermal conductivity, which makes the heat distribution even during exposure and plate making, which helps to improve the quality of imaging. At the same time, this feature reduces the loss of equipment due to overheating.

4. Good surface treatment performance

The surface of the printed aluminum plate has excellent smoothness and photosensitivity after anodizing, coating with a photosensitive layer or other treatments. This makes it excellent in imaging clarity and dot reproduction, suitable for high-precision printing needs.

5. Environmental protection and recyclability

Aluminum is a recyclable material. Used aluminum plates can be recycled and reprocessed, which not only saves resources, but also meets the requirements of green environmental protection. This feature is favored by more and more environmentally friendly printing factories.

Uses of printed aluminum plates:

Printed aluminum plates are widely used in the field of offset printing, including but not limited to the following:

Commercial printing: such as leaflets, brochures, posters, etc.

Packaging printing: such as food packaging, cosmetic packaging.

Publishing printing: such as books, magazines, newspapers.

Industrial decoration: such as metal nameplates, billboards.