If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

Green printing aluminum plate

Green printing aluminum plate refers to aluminum-based plates produced by environmentally friendly materials and processes in the printing platemaking process, aiming to reduce the impact on the environment and meet the requirements of sustainable development.

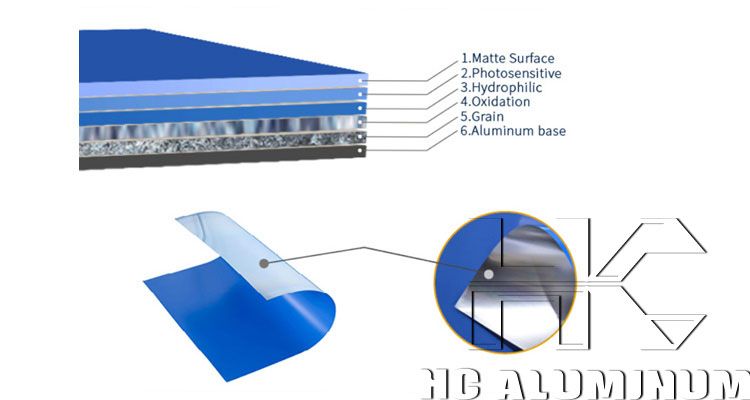

Aluminum substrate is the main carrier of green printing aluminum plate. It is usually made of high-purity aluminum, using 1050 aluminum alloy, 1060 aluminum alloy, etc., with the characteristics of light weight, high strength, corrosion resistance, good thermal conductivity and strong plasticity. The surface of the aluminum plate is anodized and coated to improve wear resistance and hydrophilicity, which is very suitable as a substrate for printing plates.

Advantages of printed aluminum plate:

1. Reduce pollution: Use water development or no development technology to reduce the discharge of harmful waste liquid and reduce air pollution.

2. High-quality printing: The surface flatness and coating uniformity of the plate are good, which can meet the needs of high-precision printing.

3. Long printing life: Aluminum-based materials have good corrosion resistance and wear resistance, suitable for long-run printing, and reduce the frequency of plate replacement.

4. Recyclable and reusable: Aluminum plates can be recycled and reprocessed multiple times to reduce material costs.

5. Improved production efficiency: With advanced platemaking technology and printing equipment, green printed aluminum plates can achieve fast platemaking and efficient printing, which improves production efficiency

6. Easy to process: Aluminum plates have good processability and can be cut, bent, punched and processed according to customer needs to meet different application scenarios.

Green printed aluminum plates are suitable for offset printing, packaging printing, commercial printing and other printing fields.

Key points of quality control:

1. Surface cleanliness of aluminum coils: Before platemaking, ensure that the surface of the aluminum coil is free of oil, scratches and impurities to improve the adhesion of the photosensitive coating.

2. Coating uniformity: The coated photosensitive layer should be uniform and consistent to avoid local uneven thickness, which affects the exposure and development effect.

3. Exposure accuracy: CTP/PS platemaking requires precise optical control to ensure the clarity and contrast of the image.