If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

PS plate aluminum base for printing

Definition of PS plate for printing:

PS plate (pre-sensitized plate) aluminum plate base for printing is a commonly used printing plate material in modern offset printing. Its main component is a high-purity aluminum alloy plate base, which is coated with a layer of photosensitive coating after surface treatment to form a PS plate that can be used for printing.

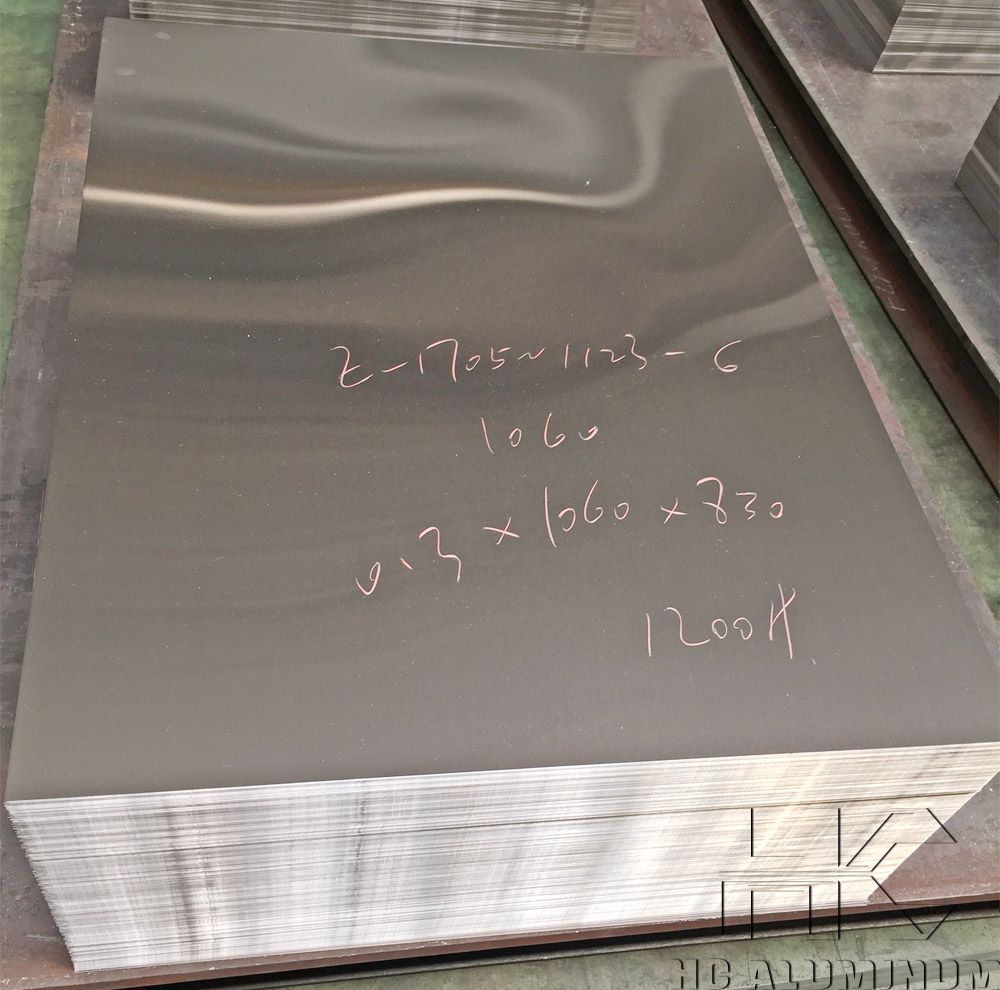

PS plate aluminum plate base usually uses high-purity aluminum alloy, which has good corrosion resistance and thermal conductivity. Commonly used aluminum alloys include 1050, 1060 and other series. They have good plasticity and processing performance, which can fully meet the requirements of conventional processing (stamping, stretching), and are commonly used materials for PS plate aluminum plate base.

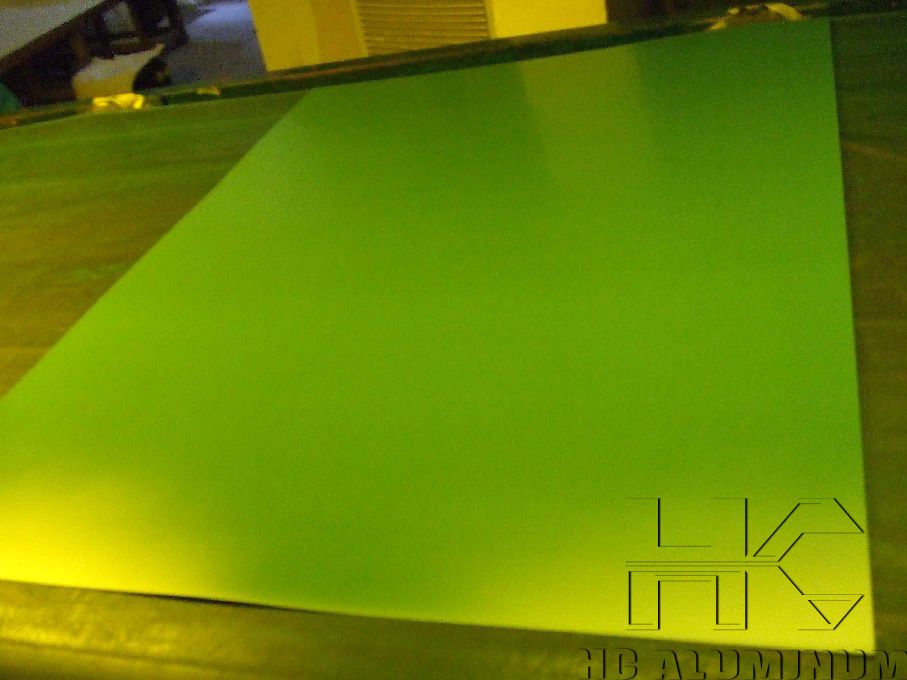

Surface treatment of aluminum plate:

The surface of the aluminum plate base undergoes multiple processing procedures, such as surface roughening, anodizing and sealing, to enhance the hydrophilicity of the plate surface and the adhesion of the coating, while improving the wear resistance and chemical corrosion resistance of the aluminum plate.

(1) Roughening treatment: Through chemical or electrochemical methods, tiny pits are formed on the surface of the aluminum plate to improve the adhesion of ink.

(2) Anodizing: A layer of aluminum oxide film is formed on the surface of the aluminum plate to further improve corrosion resistance and wear resistance.

(3) Sealing treatment: After anodizing, the tiny holes are sealed to prevent chemical substances from entering and increase the service life of the plate.

PS plate aluminum plate base specifications:

| Alloy | 1050, 1060, 1070, etc |

| Temper | H18 |

| Thickness | 0.13-0.4mm |

| Width | 100-1600mm |

| Length | C |

| Application | positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates |

| MOQ | 1-3 tons |

| Sample | free |

| Packaging | standard export wooden box |

| Delivery time | 25-35 days after payment |

Performance advantages of aluminum plate for printing PS plate

1. Corrosion resistance: After anodizing, a layer of aluminum oxide film is formed on the surface of the aluminum plate, which has strong corrosion resistance and can resist the erosion of moisture, chemicals and ink during printing, extending the service life of the plate.

2. Easy processing: Aluminum alloy materials have good plasticity and processing performance, which is convenient for various process processing in production, such as cutting, bending and surface treatment.

3. Strength and toughness: High-purity aluminum alloy material has good strength and toughness, can withstand the pressure and friction of the machine during printing, and is not easy to deform.

4. Surface flatness: The aluminum plate base has excellent flatness, which enables the image to be uniform and consistent during the printing process, reduces printing errors, and ensures high-quality printing effects.

5. Thermal conductivity: Aluminum has good thermal conductivity, can quickly dissipate heat during the printing process, prevent the printing equipment from overheating under long-term operation, maintain the stability of the printing plate and extend its service life.

6. Photosensitive performance: The photosensitive coating on the aluminum plate base is very sensitive to exposure, has a fast exposure speed, clear images and high resolution, and can achieve fine image performance. After exposure and development, the photosensitive layer can accurately restore the image area to ensure the precise transfer of ink during the printing process.

7. Environmental protection and recycling: Aluminum is a renewable and recyclable resource that meets environmental protection requirements.

8. Low cost: Mature platemaking technology and low material cost reduce overall printing costs.

PS plate surface quality requirements for aluminum plate base:

1. PS plate base aluminum strip has very high requirements for surface quality and straightness. In order to obtain high-quality PS plate base strip, a special straightening method must be adopted after cold rolling.

2. The grit value of PS plate is generally in the range of 0.15mm-0.50mm, and its surface roughness parameter Ra is required to be 0.40-0.90μm. Fine printing parts require finer grit, generally around 0.60-0.80μm. To obtain finer grit, the intrinsic composition of the aluminum plate base is the key, that is, it is related to the content and composition of trace special metals contained in the aluminum alloy.