What is positive PS plate?

Positive PS plate is a lithographic printing plate with a photosensitive resin layer pre-coated by the manufacturer on 1050 aluminum plate (Hongchang Aluminum Products) and the like.

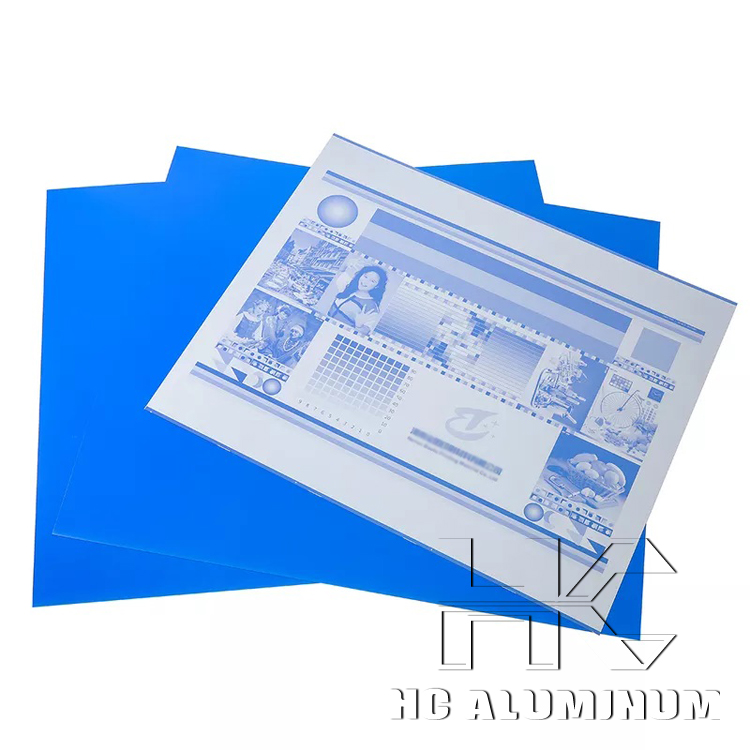

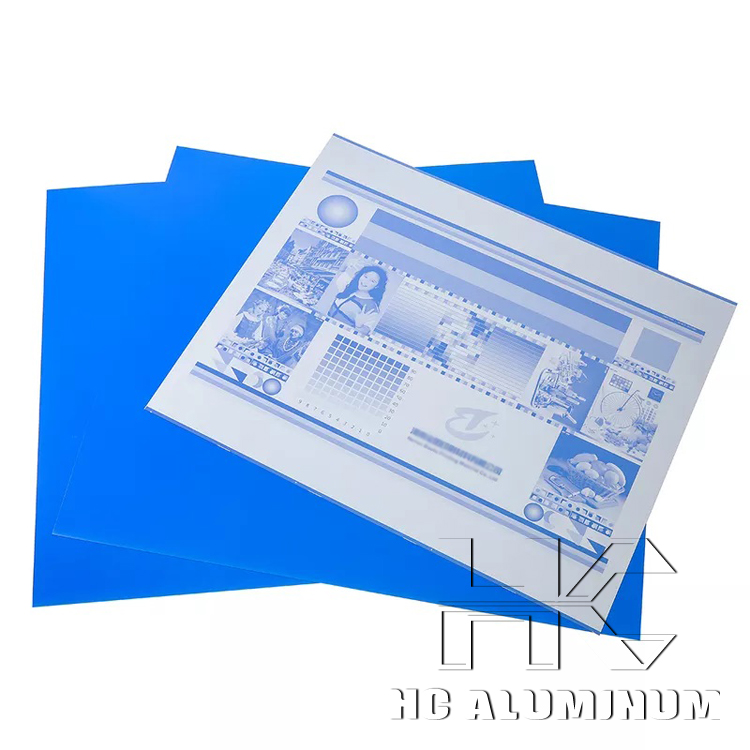

Positive PS plate refers to the use of positive original plate. The exposed ultraviolet light passes through the low-density and blank areas on the original plate to reach the photosensitive layer of the PS plate, and is absorbed by the photosensitive agent until it is photosensitive to form characters and images.

Positive PS plate is used in high-end commercial color printing and newspaper printing. Positive PS plate has the characteristics of stable performance, fast sensitivity, large development tolerance, and high printing durability. The unique production and manufacturing technology and high-quality raw material supply have created the ultra-high sensitivity, fine dot reproduction and excellent stability of Hongchang plate materials.

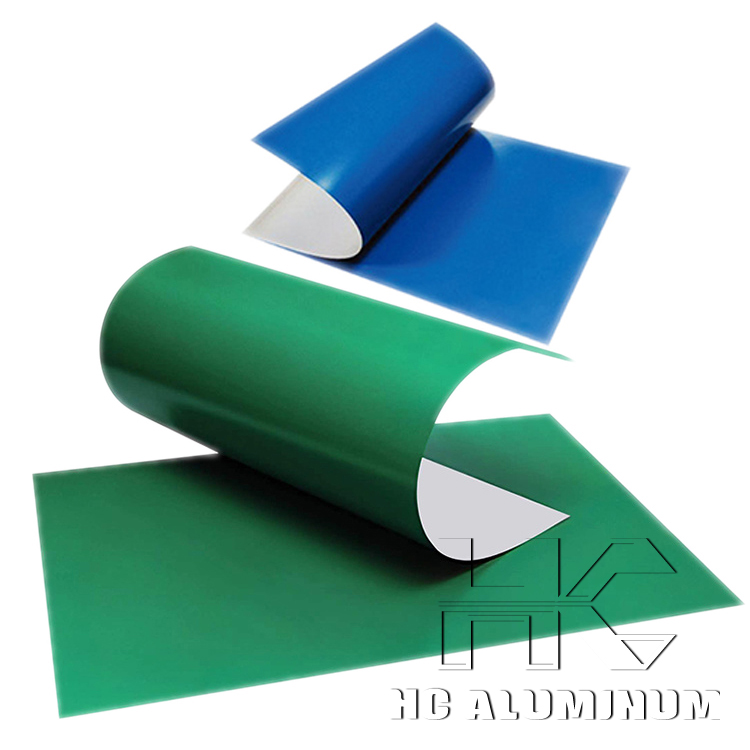

PS board substrate

PS plate substrate selection:

Positive PS plate substrate is usually high-quality aluminum, such as 1050A, 1060, 1070, 1100 and other aluminum alloys, which are corrosion-resistant, durable, stable and highly flat on the surface, ensuring the printing quality and stability of PS plates.

Positive PS plate principle:

Under the action of ultraviolet light, the positive PS plate undergoes decomposition and structural rearrangement reactions, making the photosensitive part change from insoluble in dilute alkali to soluble in dilute alkali. At the same time, as the photosensitive group disappears, the color of the photosensitive part changes from green to the color of the pigment in the photosensitive layer - blue.

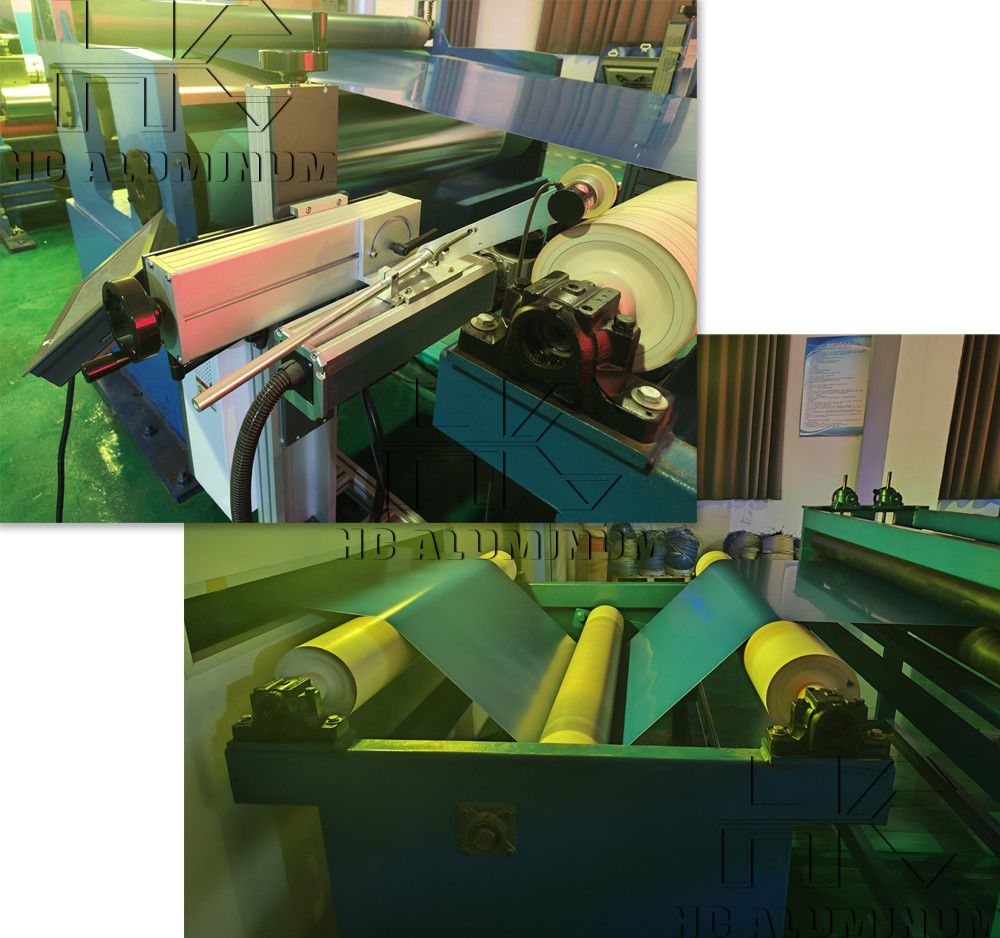

Positive PS plate production process:

PS plate is a lithographic printing plate with a photosensitive resin layer pre-coated on an aluminum plate. When used, it is directly exposed and developed to complete the plate making.

Exposure-development (PS plate developer)-dirt removal and repair-baking-inking-gluing

Specification

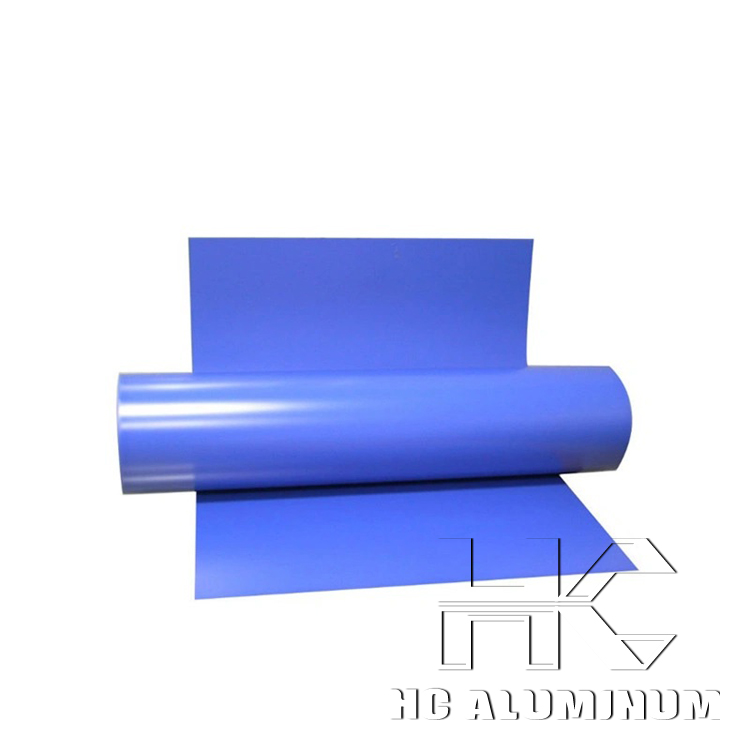

Positive PS plate specifications:

| Material | Aluminum |

| Aluminum alloy | 1050 aluminum alloy |

| Coating | IR sensitive, positive acting |

| Coating color | green, blue |

| Thickness | 0.15mm, 0.20mm, 0.25mm, 0.30mm, 0.40mm |

| Max width | 1380mm |

| Length of Run | Unbaked: 50000 to 80,000 impressions |

| Baked | Over 100000 impressions |

| Usage | Offset Printing, Digital Printing |

| Trademark | HONGCHANG or customized |

| Developer | Temperature:23+/-2 Degree |

| Laser Energy Required | 80-180mj/Cm2 |

| Transport Package | Export Standard Seaworthy Package |

Features

Advantages of positive PS plate:

1. Good stability

2. Large tolerance, easy operation, strong adaptability to printing environment.

3. High sensitivity

4. Applicable to all mainstream platemaking machines, developers and developers

5. Ultra-high resolution and press run

6. Faster exposure time and excellent stability.

7. Dot restoration, good ink affinity, high press run.

8. High-quality aluminum plate (1050/1060/1050A/1070) is processed by electrolytic grinding, anodizing and other processes

Packaging

Storage conditions: temperature 5-30°C, RH: ≤65°C, stacking height: ≤1.2m

Applicable to 405nm CTCP printing; development system.