If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

Aluminum plate for printing house

Aluminum plate is an important printing material, mainly used for layout production in the printing process. Its name reflects its material and use, that is, it is a printing plate made of aluminum alloy. It is widely used in printed materials such as books, magazines, newspapers, etc. with long printing cycles and requiring accurate layout.

The aluminum plates used in printing houses are mainly PS plate aluminum plate base and CTP plate aluminum plate base, generally made of 1050, 1060, 1070 and other aluminum alloy materials, with aluminum content ≥99.50%, ≥99.60%, ≥99.70%, thickness range 0.14-0.5mm, state H18. Aluminum plate has the advantages of low density, high strength, moderate wear resistance, good forming, high stability, and good surface treatment.

Features of 1 series aluminum plate for printing:

1. Lightweight: The aluminum plate is light in weight and easy to carry and operate.2. High precision: The surface is flat and the image transfer accuracy is high.

3. Strong durability: The treated aluminum plate has good corrosion resistance and durability.

4. Excellent thermal conductivity: It helps to achieve fast and uniform printing effects.

5. Machinability: The aluminum plate has good plasticity and machinability, and is easy to cut, grind, bend and punch.

6. Environmental protection: Some PS plates can be reused to reduce waste.

Production process:

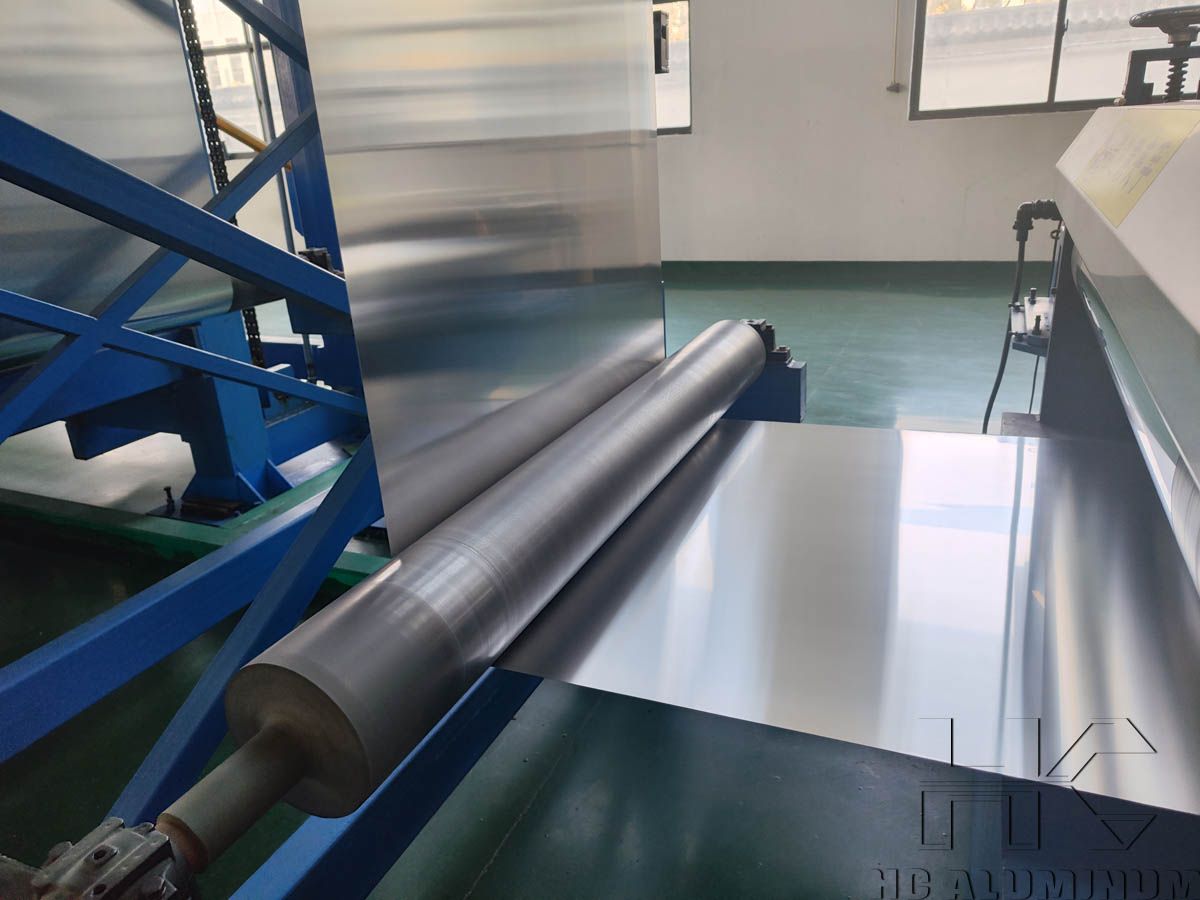

PS/CTP plates are rolled into thin plates of a certain thickness through hot and cold rolling processes. The surface of the plate is coated with a layer of photosensitive resin after a specific process treatment, and then dried to make printing plates for various purposes.

Classification and use:

General printing plate: used for ordinary printing, it needs to have good hydrophilicity and ink adsorption to ensure the clarity and integrity of the printed images.

Color printing plate: suitable for color printing, with high requirements on the surface flatness and color consistency of the aluminum plate, and also needs to have good anodizing performance for subsequent surface treatment.

CTP board: It is an aluminum plate substrate for computer direct plate making, which requires higher precision and stability, as well as good simulated electrolytic performance.

PS/CTP aluminum plate base quality requirements:

1. Surface quality: The surface should be flat and smooth, without obvious scratches, abrasions, oil stains, oxidation spots and other defects to ensure the platemaking quality and printing effect of the printing plate.

2. Thickness tolerance: The thickness tolerance should be controlled within a small range to ensure the flatness and registration accuracy of the printing plate during the printing process.

3. Mechanical properties: The aluminum plate should have appropriate hardness and strength to withstand the pressure and friction during the printing process, and should also have good toughness and ductility to prevent cracking, deformation and other problems during the platemaking and printing process.