If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

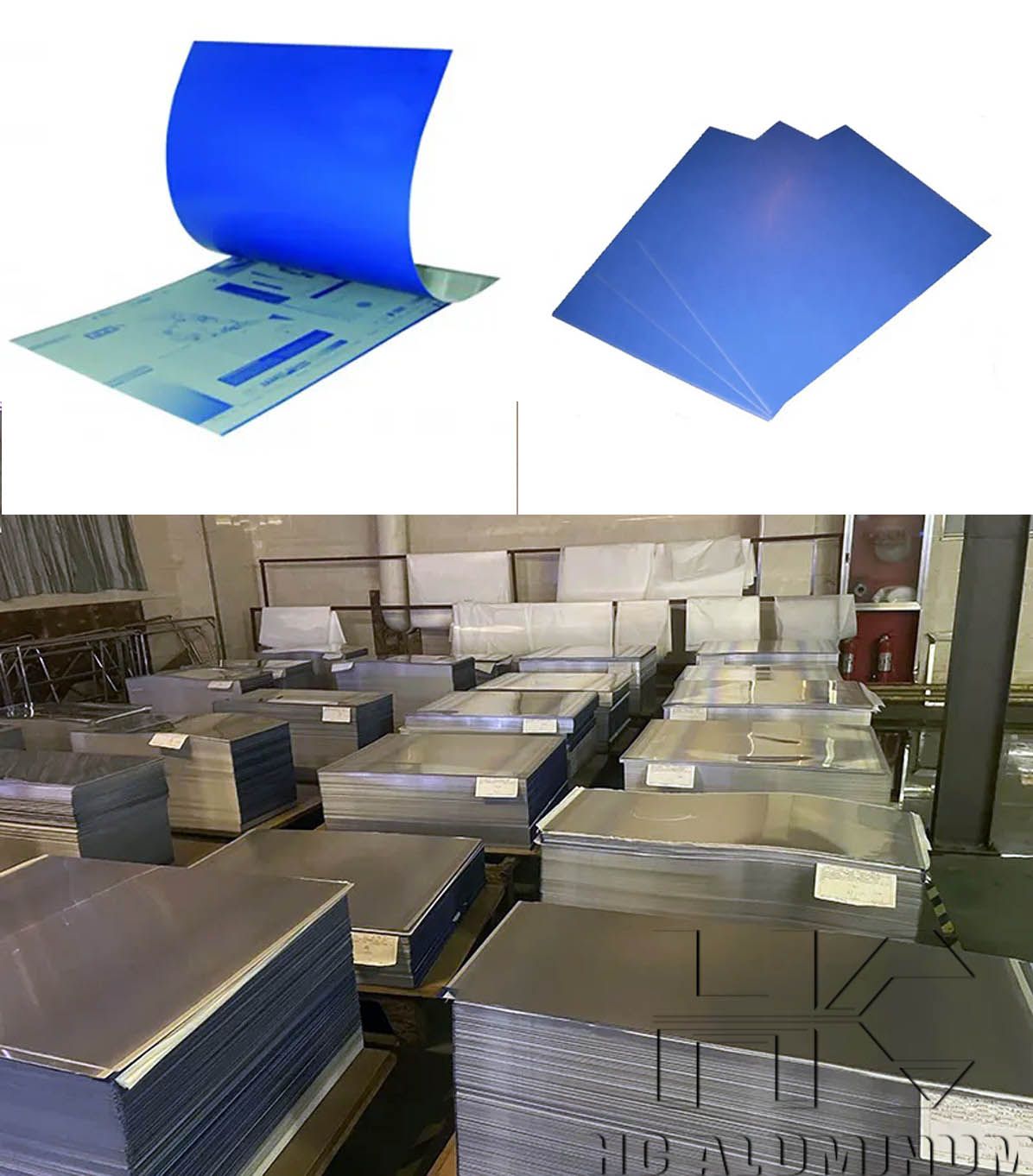

Differences Between CTCP and CTP Plates

CTCP plates transfer image data directly to traditional PS plates (photosensitive plates) via computer, using ultraviolet (UV) light for exposure. This technology simplifies traditional plate-making processes, offering lower costs and making it suitable for small and medium-sized printing businesses with lower printing quality requirements. CTCP plates are typically made of traditional aluminum sheets (1050, 1060, 1070, etc.) with an oleophilic photosensitive coating, providing advantages such as simple plate-making processes, low cost, good dot reproduction, and high printing durability.

CTP plates are specially designed for direct computer-to-plate imaging, using laser technology (thermal or violet laser) to burn images directly onto the plate surface, eliminating the need for film production. CTP plates deliver high-quality and high-precision images, making them widely used in high-end printing applications such as packaging and publishing. CTP plates are mainly made of aluminum substrates, commonly 1050 and 1060 aluminum sheets, with photosensitive coatings consisting of thermal-sensitive or UV-sensitive materials.

CTCP and CTP are both computer-to-plate technologies, but they differ significantly in terms of plate type, imaging process, cost, and applications.

Key Differences Between CTCP and CTP

1.Plate Type

CTCP Plate: Uses traditional PS plates (photosensitive resin plates), originally designed for conventional film-based plate-making but later adapted for CTCP equipment.

CTP Plate: Uses specialized CTP plates (such as thermal CTP and violet laser CTP plates), with a photosensitive coating designed exclusively for computer-to-plate technology and not suitable for traditional processes.

2.Imaging Process

CTCP: Uses ultraviolet (UV) light to expose traditional PS plates, similar to conventional plate-making but without the need for film.

CTP: Uses laser technology (thermal or violet laser) to expose specialized CTP plates directly, completely eliminating film and PS plates.

3.Equipment and Operating Costs

CTCP: Lower equipment costs, compatible with traditional PS plates, and lower plate-making material costs, making it ideal for budget-conscious printing companies.

CTP: Higher equipment costs and more expensive CTP plates, but it offers superior plate-making precision, suitable for high-end printing.

4.Application Scope

CTCP: Mainly used in commercial printing and small to medium-sized printing businesses, especially those already utilizing PS plates, allowing for an easy transition.

CTP: Ideal for high-precision printing, such as packaging, publishing, and large-scale commercial printing, catering to businesses demanding high-quality output.

5.Printing Quality and Durability

CTCP: Lower precision compared to CTP, with a typical durability of up to 100,000 impressions, suitable for standard printing needs.

CTP: Higher precision, better dot reproduction, and greater durability (some CTP plates can last for hundreds of thousands of impressions), making it ideal for high-quality printing.

6.Environmental Considerations

CTCP: Still requires traditional chemical processing with developer solutions, resulting in a higher environmental impact compared to CTP.

CTP: Some CTP plates (such as process-free CTP plates) can eliminate or significantly reduce chemical processing, making them more environmentally friendly.

If your printing needs prioritize cost control and compatibility with traditional PS plates, CTCP is a good choice. However, if you seek superior printing quality, durability, and environmental benefits, CTP is the better option.

About MC Aluminum

MC Aluminum is a professional manufacturer of offset printing aluminum plates, offering high-quality aluminum sheets and coils such as 1050, 1060, 1070, and 1100 grades. Our products feature a smooth surface, free from black streaks, scratches, or rough edges. With high-quality standards, international exports, free samples, competitive prices, and excellent after-sales service, you can order with confidence.