If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

0.15-0.30mm Aluminum PS Plate for Offset Printing Machines

Aluminum PS plates (pre-coated photosensitive plates) with a thickness range of 0.15-0.30mm are a core consumable for offset printing machines.

The base material of aluminum PS plates is mainly 1050, 1060, and 1070 aluminum alloys, in the H18 temper (fully cold-hardened). The surface undergoes electrolytic oxidation treatment to form a grain (sand grain) structure with a depth of 3-6 μm, and is coated with a photosensitive resin.

The plate is exposed to UV light (e.g., wavelength 300-400 nm) in a plate-making machine, then developed with an alkaline developer to remove the exposed areas and reveal the hydrophilic grain layer. The unexposed areas retain the oleophilic image, enabling printing through the water–ink balance principle of offset lithography.

Why Choose a 0.15-0.30mm PS Printing Plate?

A thickness of 0.15-0.30mm falls within the industry standard range and fits the plate-clamping systems of most offset presses. This range ensures a printing endurance of typically 50,000-100,000 impressions while keeping raw material costs under control - making it the preferred choice for most printing houses.

Features of Aluminum Offset PS Plates

1. Corrosion Resistance

In humid printing environments and in contact with chemical developers, the aluminum base remains stable and resistant to corrosion.

2. High Flatness

Premium aluminum PS plates are stretched, leveled, and anodized, resulting in a smooth surface that improves registration accuracy.

3. Compatibility and Adaptability

Compatible with UV inks and mainstream offset presses; available in various thicknesses; suitable for sheet-fed or high-speed printing; strong chemical resistance.

4. Printing Endurance

Standard endurance is 50,000-100,000 impressions; with optimized processing, can be increased to 200,000 impressions. Avoid excessive water/ink roller pressure or pH imbalance in fountain solution to reduce wear.

5. Efficiency and Cost-Effectiveness

Fast photosensitivity, wide development latitude, excellent dot reproduction, significantly reducing plate-making time and costs.

Applications of PS Plates in Offset Printing

Commercial Printing: Newspapers, magazines, books, and posters.

Packaging Printing: Cartons, labels, and various packaging materials.

Other Printed Materials: Flyers, brochures, postcards.

Technical Requirements of Offset Presses for Printing Plates

1. Thickness and Flatness

Offset presses require uniform plate thickness and minimal flatness deviation. Aluminum PS plates meet these requirements through precision rolling and surface treatment.

2. Printing Endurance

Standard endurance: 50,000-100,000 impressions.

After baking (230-250°C, 1-2 minutes): Can exceed 200,000 impressions.

Compared with flexo plates: Flexographic plates can achieve over 1 million impressions, but aluminum PS plates are more than efficient enough for offset printing.

3. Chemical Stability

The aluminum oxide layer is corrosion-resistant and compatible with the chemical environment of offset fountain solutions (pH 5–6), preventing substrate corrosion.

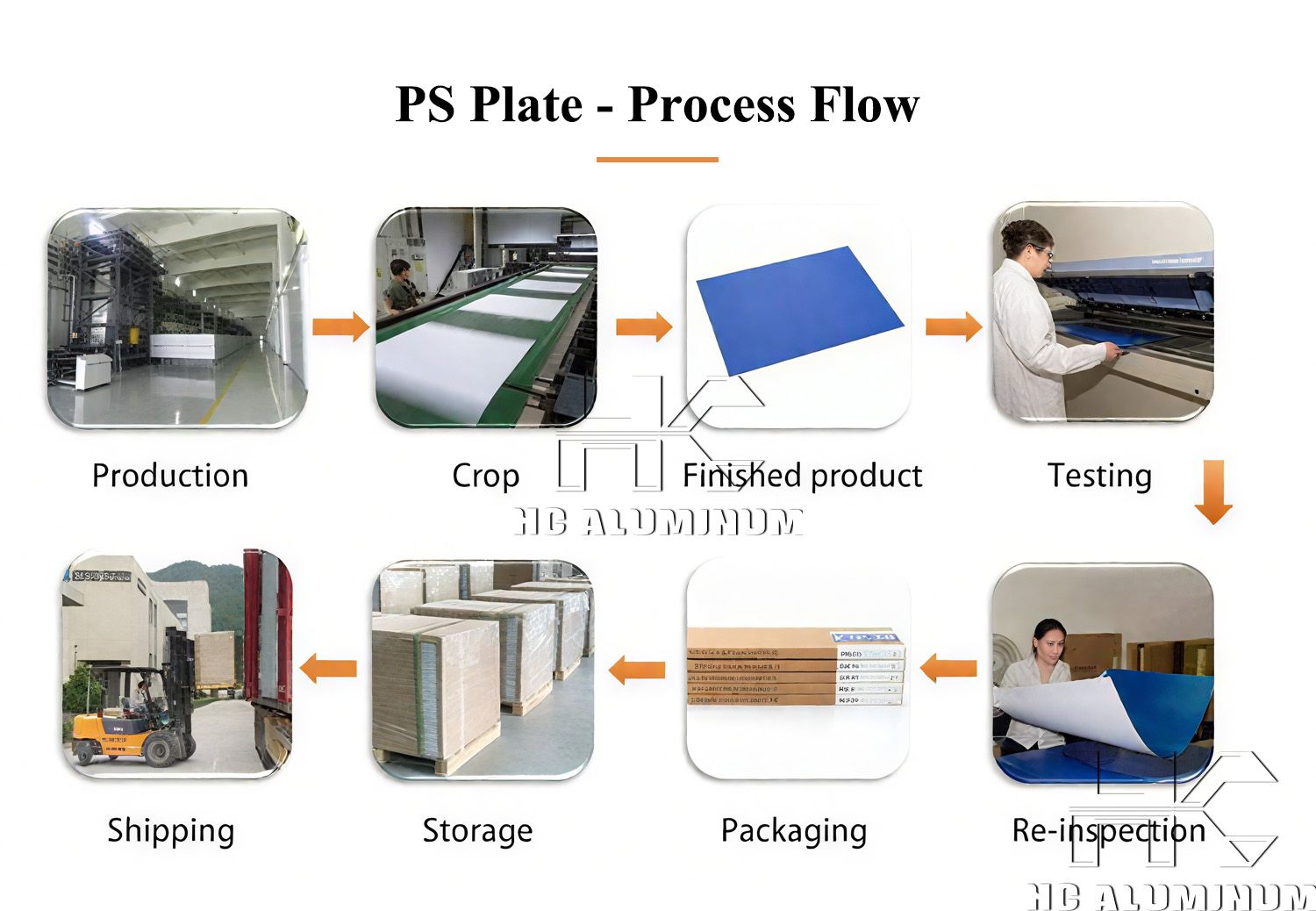

HONGCHANG Aluminum produces aluminum PS plates in the 0.15-0.30mm thickness range for positive PS plates and CTP plates used in offset printing. By optimizing rolling precision, surface treatment processes, and plate-baking procedures, we further enhance performance to meet high-efficiency printing demands. Our products are exported to multiple countries and regions worldwide, with large production capacity, short lead times, and competitive prices.

Website: https://www.printarea-plate.com/a/015-030mm-aluminum-ps-plate-for-offset-printing-machines.html

Keyword: PS plate aluminum PS plate PS printing plate aluminum substrate aluminum printing plate material aluminum offset PS plate 1050 aluminum sheet 1060 aluminum sheet 1070 aluminum sheet aluminum PS plate manufacturer